MAINTENANCE

SCHEDULED MAINTENANCE

The lifespan of the machine and its maximum operating safety are ensured by correct and regular maintenance.

See the GENERAL INFORMATION and SAFETY paragraphs.

Provided below is the Scheduled Maintenance Table. The intervals shown may vary according to particular working conditions,

which are to be dened by the person in charge of the maintenance.

For instructions on maintenance procedures, see the following paragraphs.

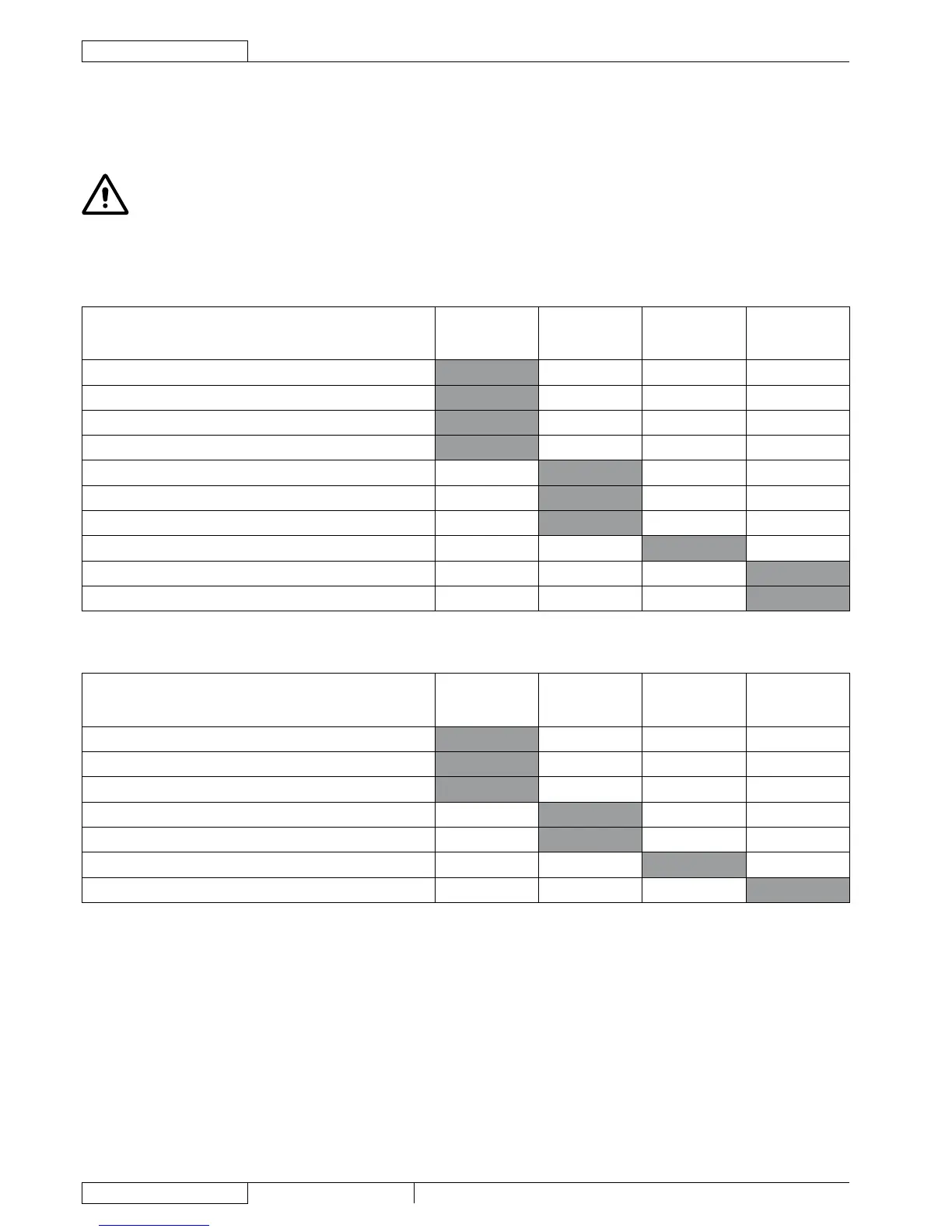

SCHEDULED MAINTENANCE TABLE [MICROMATIC M17B]

Procedure

Daily or after

using the

machine

Weekly

Every six

months

Yearly

Squeegee cleaning

Brush cleaning

Tank and vacuum grid with oat cleaning

Battery charging

Squeegee blade check (and replacement)

Solution lter cleaning

Battery (WET) uid level check

Screw and nut tightening check (1)

Brush motor carbon brush check or replacement

Vacuum system motor carbon brush check or replacement

(1): and after the rst 8 working hours

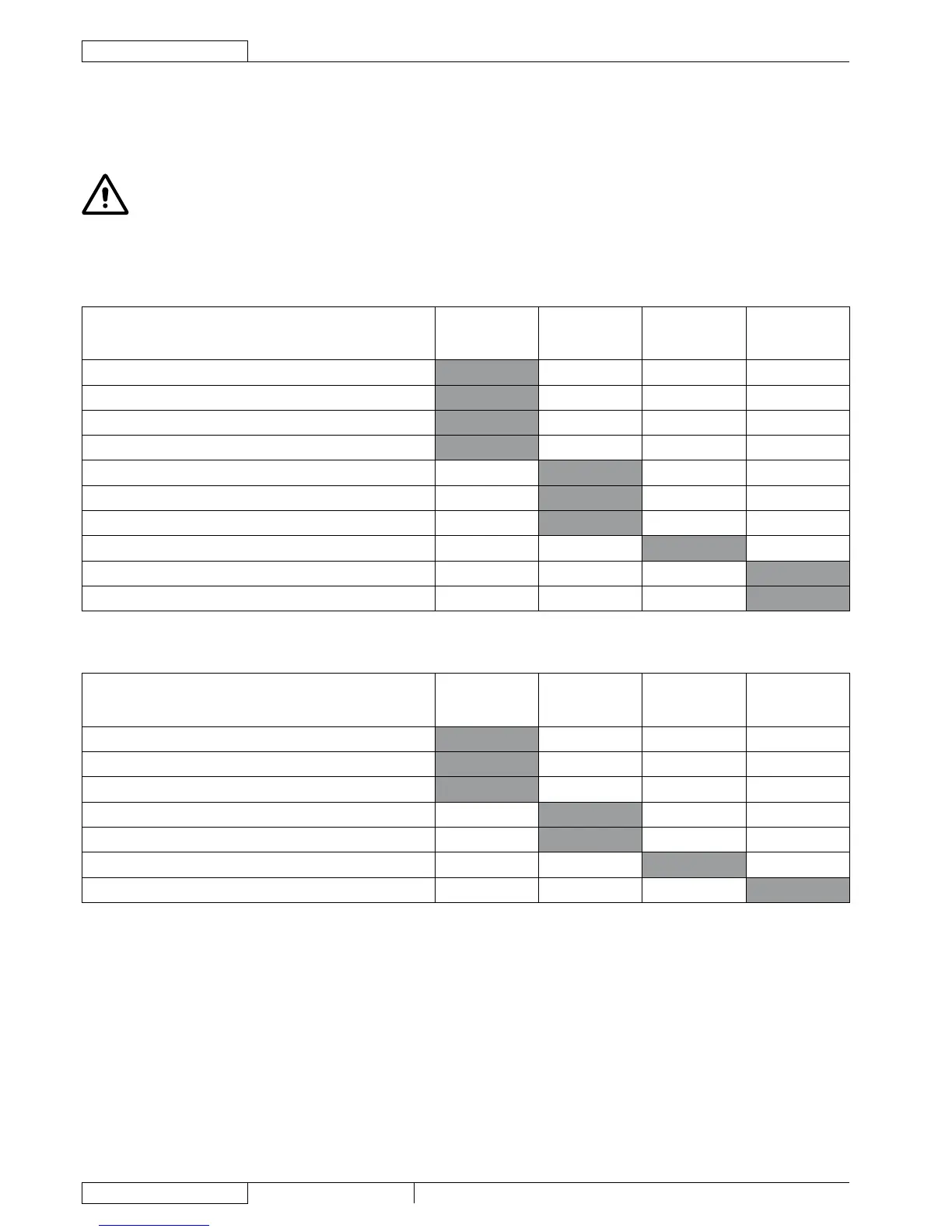

SCHEDULED MAINTENANCE TABLE [MICROMATIC M17E]

Procedure

Daily or after

using the

machine

Weekly

Every six

months

Yearly

Squeegee cleaning

Brush cleaning

Tank and vacuum grid with oat cleaning

Squeegee blade check (and replacement)

Solution lter cleaning

Screw and nut tightening check (1)

Vacuum system motor carbon brush check or replacement

(1): and after the rst 8 working hours

Loading...

Loading...