5

WORKING WITH

PLASTIC TUBING

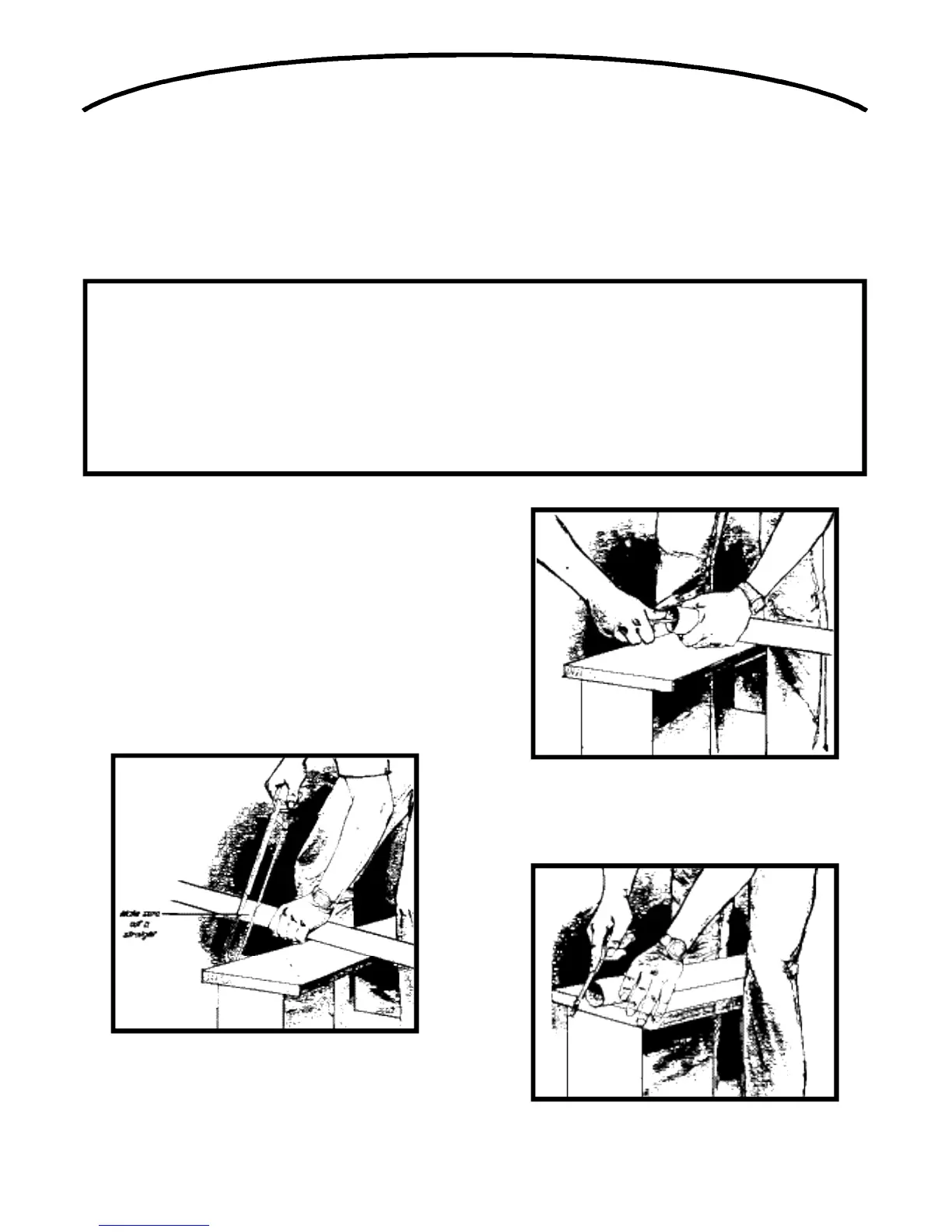

Cutting the Tubing

Before you cut a length of tube, accurately measure the

length you need. Allow 5/8” of tubing for inserting into fit-

tings and 1 1/2” for placing into flexible tubing. Cut the

plastic tubing with a hacksaw, making sure that the cut is

exactly square. (You can use a tube cutter if one is avail-

able.) Use wire cutters or tin snips to cut flexible tubing.

The 8” lengths of flexible tubing supplied with each inlet

should not be cut. See Figure 4.

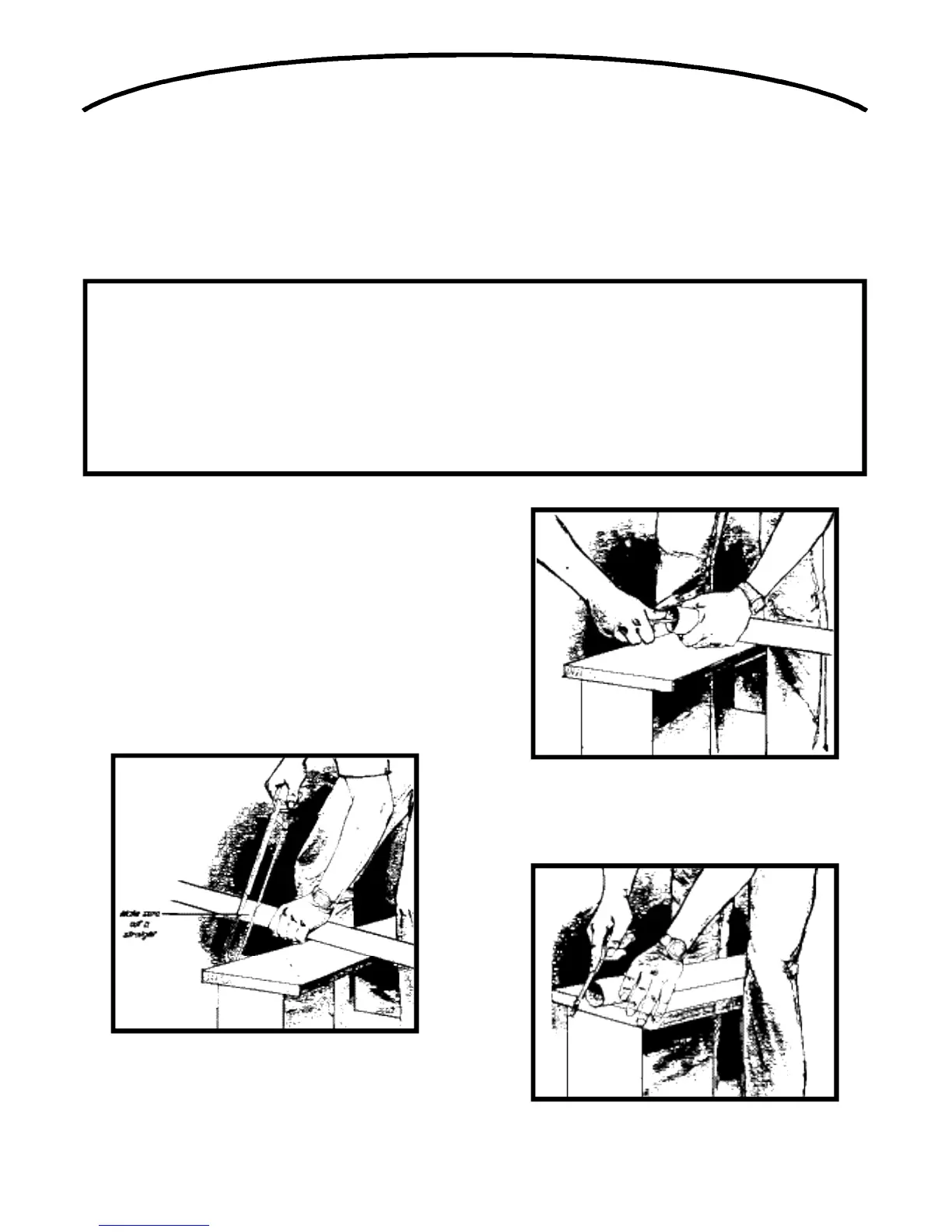

Use a small knife to remove any burrs from the inside of

the tube. You can also use steel wool to remove burrs.

The burrs must be removed or they may impede air flow

of form clogs by snagging hair and carpet thread. See

Figure 5.

Next, use a file to slightly bevel the outside of the tube so

that it will easily slide into the fitting. Use steel wool or a

light grained sandpaper to buff the surface of the tube

which will be glued. This will clean the tube and assure

a good seal. See Figure 6.

• Wire strippers • 1/4" Drill

• Utility Knife • Putty Knife

• Knife • Hammer

• 2 1/2"Hole Saw • Keyhole Saw

• 1/2" Drill • Cold Chisel

• Level • Flashlight

• Drill Bit • Electrical Tape

• Screwdriver • Safety Glasses

• Wrench • Hacksaw

• Tape Measurer

GENERAL INSTA L L ATION GUIDE

TOOL LISTING

Depending on your installation, you may require the use of these tools. The power tools are recommended

to make your installation proceed quickly.

FIGURE 4

FIGURE 5

FIGURE 6

Loading...

Loading...