GENERAL INSTALLATION

TOOL LISTING

Depending on your installation, you may require the use of

these tools. The power tools are recommended to make your

installation proceed quickly. Also, plan a mask when cutting

ducting (PVC dust) and gloves when using glue.

• Wire Strippers • 1/4’’ Drill Bit

• Utility Knife • 1/2’’ Drill Bit

• Knife • Putty Knife

• 2½’’ Hole Saw • Keyhole Saw

• Hammer • Cold Chisel

• Level • Flashlight

• Drill • Electrical Tape

• Screwdriver • Safety Glasses

• Wrench • Hacksaw

• Tape Measure

WORKING WITH PLASTIC TUBING

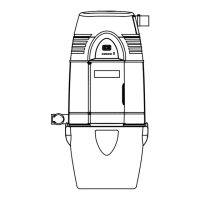

Cutting Tubing

Before you cut a length of tube, accurately measure the

length you need. Allow 5/8” (16 mm) of tubing for inserting

into fittings and 1½” (38 mm) for placing into flexible tubing.

Cut the plastic tubing

with a hacksaw, making

sure that the cut is exactly

square. (You can use a

tube cutter if one is

available.) Use wire cutters

or tin snips to cut flexible

tubing, 8” (203 mm)

lengths of flexible tubing

should not be cut. Refer

to Figure 4.

Use a small knife to

remove any burrs from

the inside of the tube.

You can also use steel

wool to remove burrs.

The burrs must be

removed or they may

impede air flow of form

clogs by snagging hair

and carpet thread.

See Figure 5.

Next, use a file to slightly

bevel the outside of the

tube so that it will easily

slide into the fitting. Use

steel wool or a light

grained sandpaper to

buff the surface of the

tube which will be glued.

This will clean the tube

and assure a good seal.

Refer to Figure 6.

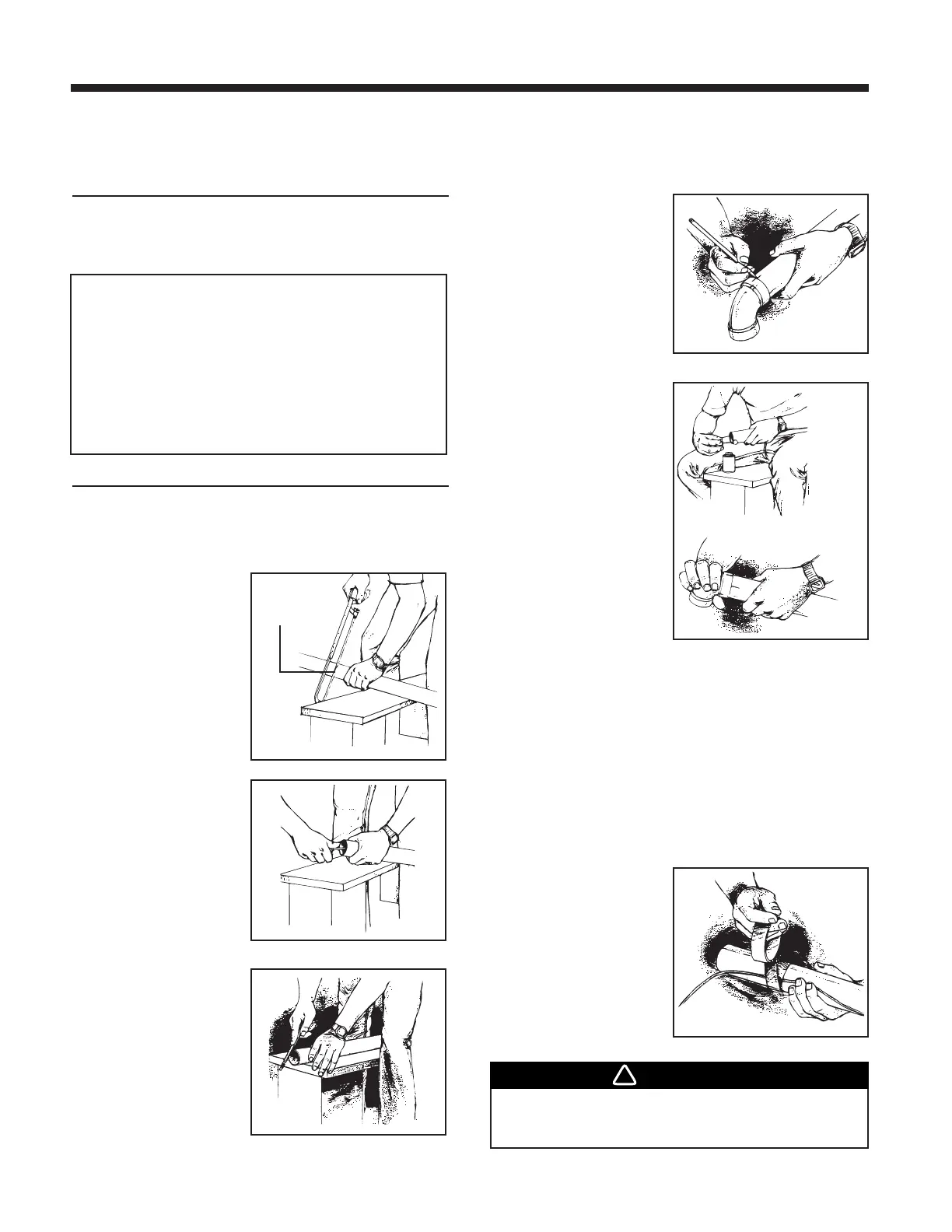

Making a Joint

Insert the tube into the

fitting, aligning the two

parts as they will be

installed. Mark the tube

and the fitting so that you

can quickly realign the

joint. Refer to Figure 7.

Apply cement only to the

outside of the tube. Dab

the cement generously in

an inch-wide (25 mm)

band. Insert the tube into

the fitting with the

alignment marks a quarter

turn apart, and then

quickly push and turn the

fitting to align the marks

and spread the cement.

Allow one minute for the

joint to dry. You may also

use electrical tape or duct

tape to further seal the

joint. Refer to Figure 8.

Cementing Flexible Tubing

Make sure the ends of the flexible tubing are even—trim if

necessary. When you join flexible tubing to plastic tubing or

to an inlet mounting plate, apply cement to both the inside of

the flexible tubing and the outside of the plastic tubing or

mounting plate tubing ring. Twist the two pieces as you join

them to evenly spread the glue. Allow five minutes for the

cement to set in flexible tubing. You may also use electrical

tape or duct tape to further seal the joint.

Secure Wire to Tubing

The low-voltage power

wiring is run along with

the tubing. To insure that

the wire is secure and will

not hang-up in a wall, use

electrical tape to attach

the wire to the tubing. Tape

the wire approximately

every 12-18 inches

(305 mm - 457 mm).

Refer to Figure 9.

Loading...

Loading...