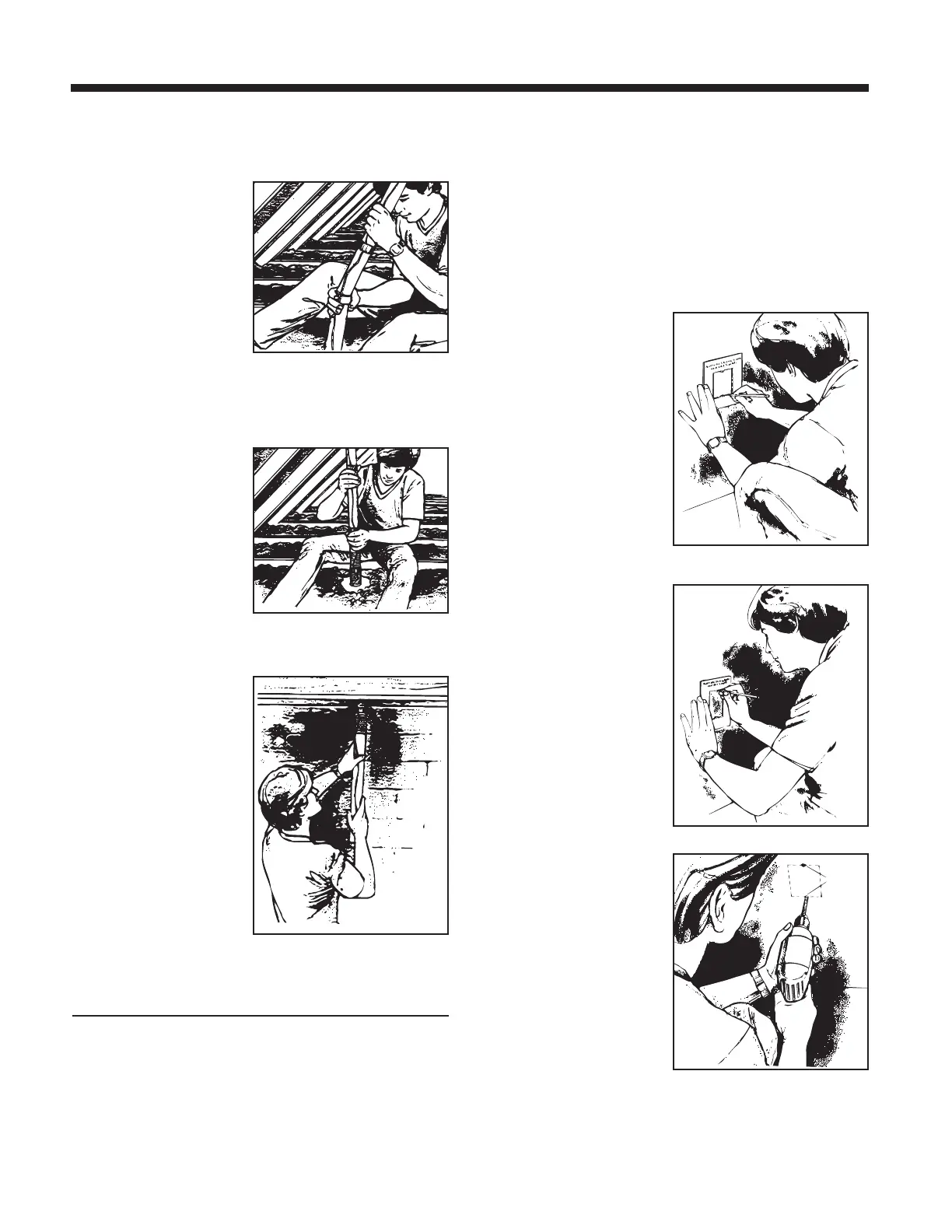

If space permits, you can

assemble the entire inlet line

by joining two sections of

tubing with a stop coupling

before dropping the

assembly into the access

hole. (Remember to only

glue the outside of the

tubing when joining two

pieces of PVC tubing.)

Oftentimes, tight attic

spaces require you to begin your drop and then join the

second section of tubing. Of course, the order of assembly,

and the length of tubing required, depend on your attic space

and your wall height.

Whatever the case, insert

the completed inlet line

into the access hole and

thread it down inside the

wall. The inlet line should

be long enough so that it

extends above the joists

in the attic; at this height, it

can be easily connected

to the branch and truck

lines. When cutting the

inlet tubing to length, remember that your inlet will be placed

18” (458 mm) above the floor.

For a basement installation,

assemble the tubing to

the inlet flexible tubing in

the same way and insert

it into the access hole. A

basement inlet line is

necessarily shorter because

it must only reach 18”

(458 mm) from the floor

to the inlet. Most of the

time, basement inlet lines

are more easily installed

by two people after the

inlet hole has been cut in

the interior wall. See

“Installing the Inlet.”

Complete all your inlet lines, and then proceed to your inlet

installations.

WALL INLET INSTALLATION

The wall inlet design allows you to work outside the wall—

where assembly is easy and all the parts you need are accessible.

First, you make a cutout into in the wall and locate the flexible

tubing attached to the inlet line which you previously threaded

into the wall. Then, you attach the flexible tubing to the inlet

mounting plate, assemble the other inlet parts, and make the

wiring connections. You place the inlet assembly into the wall

cutout, sandwiching the wall between the inner and outer

parts, and secure the inlet tightly to the wall with two screws.

Assemble and install the wall inlet as shown in the illustrations

and as explained in the next few pages. Be careful and

patient as you make your first cutout and install your first

inlet—following the procedure step by step—and the other

inlets will be easy to install in very little time.

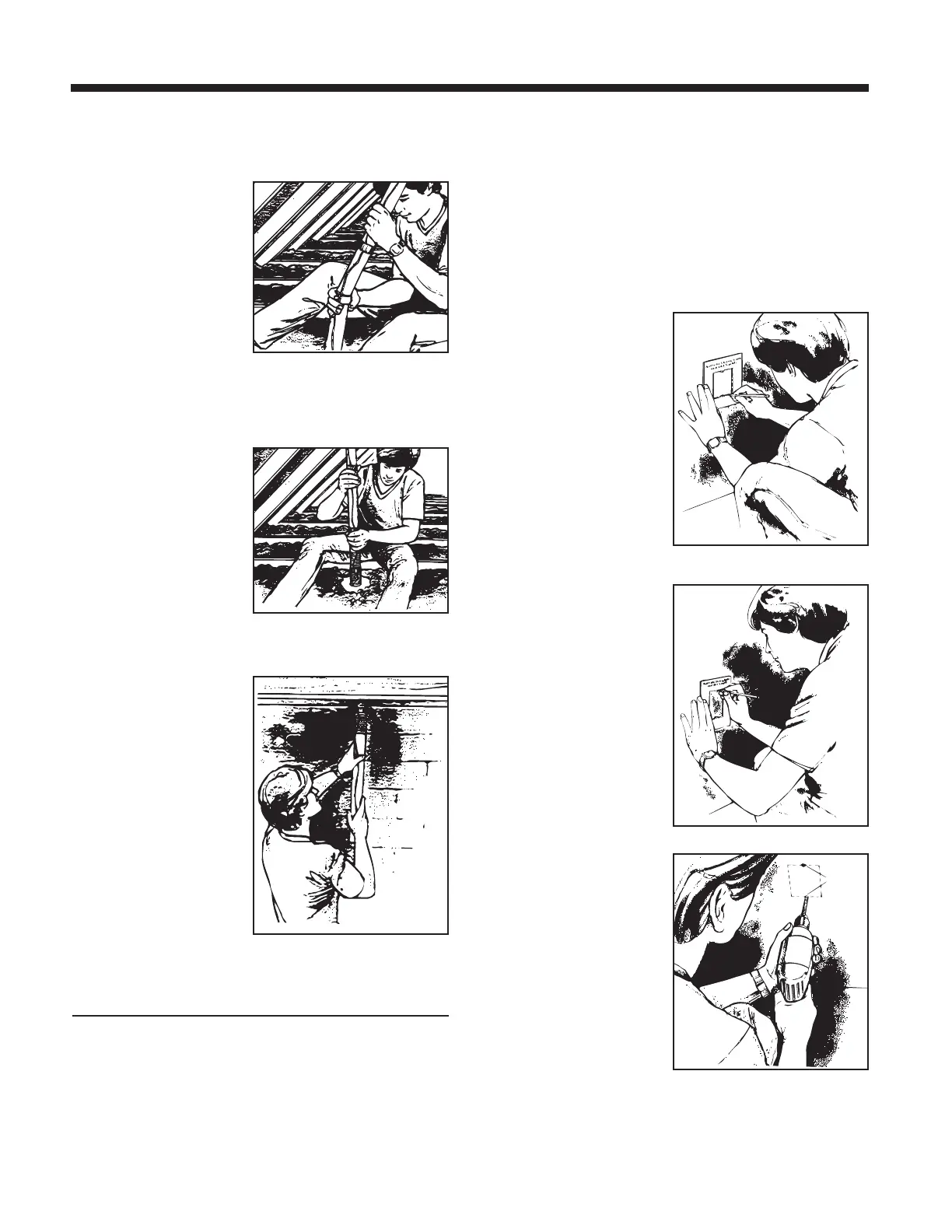

Making the Wall Inlet Cutout

The wall inlet should be

located 18” (458 mm)

on-center from the floor

and directly in line with

the attic or basement inlet

tubing hole you have

already drilled in the wall

plate or header. The wall

inlet cutout must be

exactly 3⅞” (98 mm) high

by 2⅞” (73 mm) wide. It is

crucial that you make an

accurate cutout, and we

have supplied a template

to help you.

Place the template

against the wall so that it

is 18” (458 mm) on-center

from the floor. Use a level

along the top edge of the

template to make sure it

is square to the wall.

Mark your wall for the

cutout by tracing around

the inside of the template.

Then use your pencil to

mark the screw hole

locations through punched

holes at the top and

bottom of the template.

Remove the template

from the wall.

Use an awl or ice pick to

punch pilot holes where

you marked the two hole

locations. Now, drill two

3/8” (10 mm) diameter

holes, using the pilot

holes as the centers.

Make sure to locate and

drill these holes exactly

as marked with the

template.

page 9

Loading...

Loading...