Omron TM Collaborative Robot S Series: TM12S and TM14S Hardware Installation Manual

The light module uses 4 of M3 screws to fix, and the recommended tightening torque is 1 Nm. For

higher accuracy on usages in demand, use both of the 2 ㎜ diameter openings with the positioning pins

to get the better steadiness. Users can replace the light module by applications in demand. The choice

depends on the torque load of the light module, the available load of the robot, the possible influence

the other light module made to the camera's field of view, and the electrical specifications.

1. The torque load of the light module (M): this torque load must be lower than 900 kgfmm, which is

the available strength of the camera module M3 screw can be loaded.

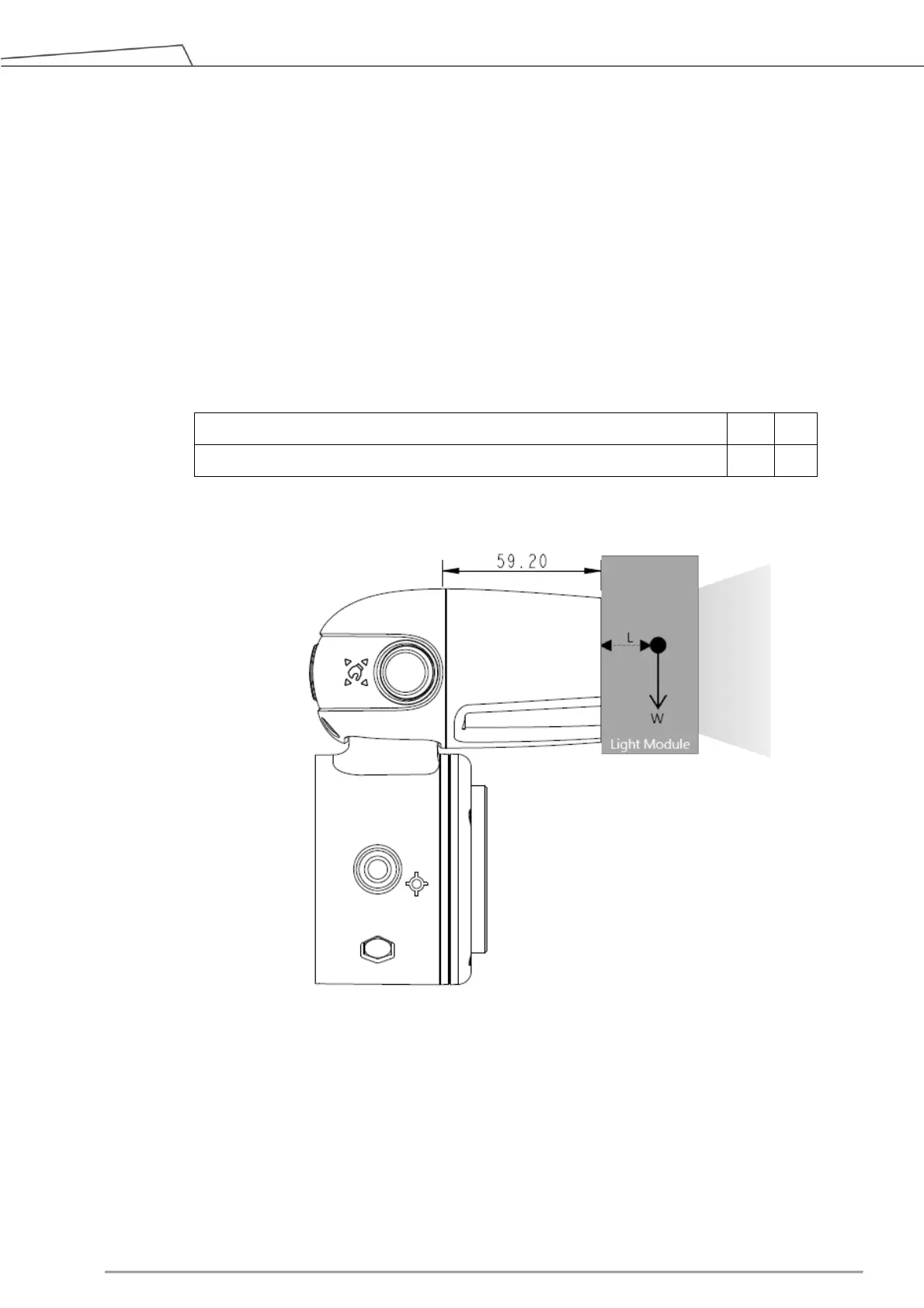

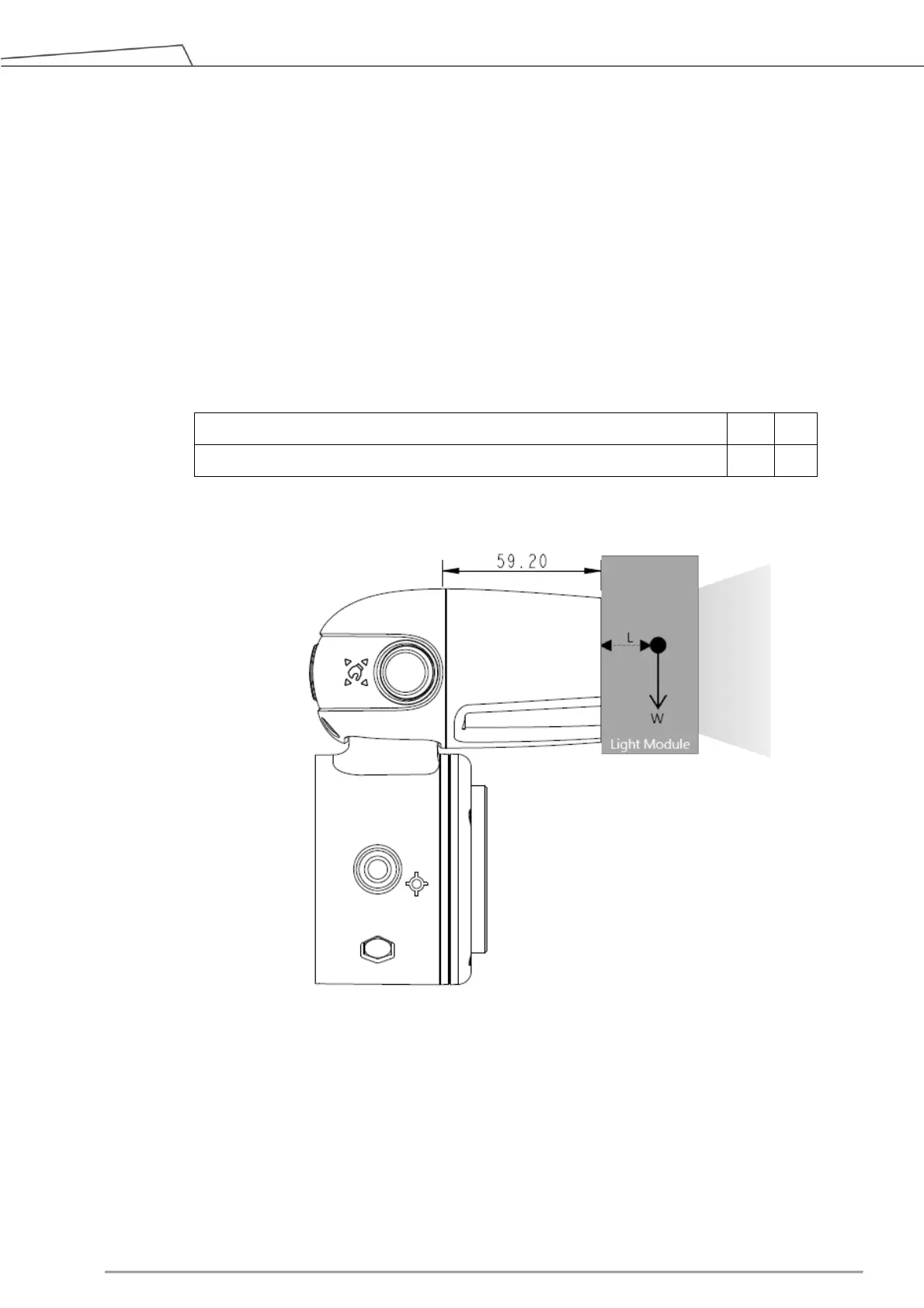

Calculation formula: M = (L+59.2)*W

The weight of the light module

The center of gravity of the light module

Table 7: Reference of the Symbol and Unit in Calculation the Torque Load of the Light Module

Figure 28: Calculation the Torque Load of the Light Module

*All measures are in ㎜.

2. The maximum allowed payload of the robot: the weight of the light module must match the relative

relationship between the maximum allowed payload and the center of gravity offset distance. If the

robot end of the flange goes with additional applications, it is required to generate the equivalent

center of gravity for its position and total load from the combination of the light module and the

application tool as well as follow 4.2.1.4 Payload and Torque of this manual.

Loading...

Loading...