Omron TM Collaborative Robot S Series: TM12S and TM14S Hardware Installation Manual

7. Maintenance and Repair

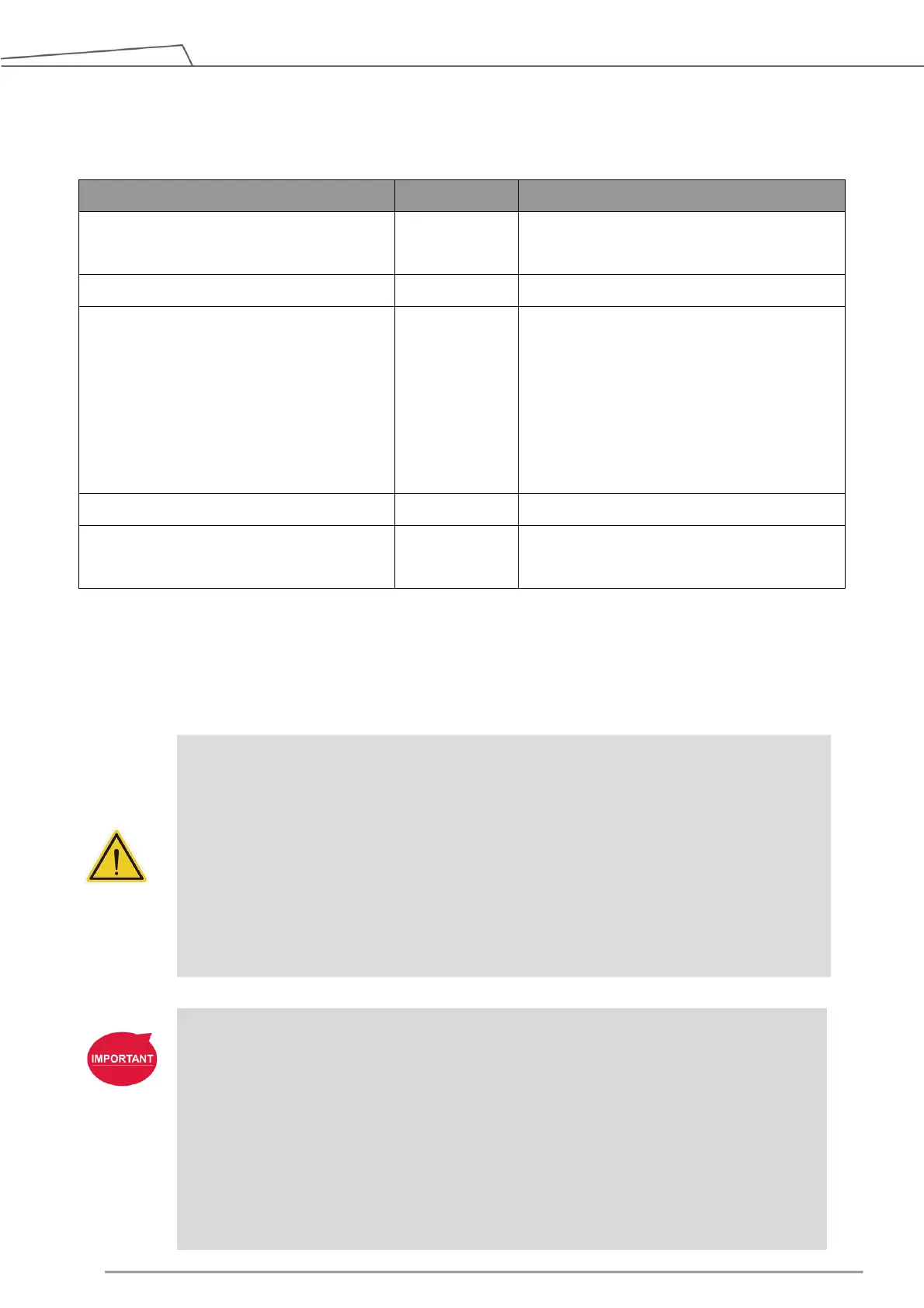

The following table gives a summary of the preventive maintenance procedures and guidelines:

Ensure the labels are present and legible.

Replace them if necessary.

Replace the filter every 3 months.

Check Emergency Stop Functions,

Check Enabling Switch Functions,

Check Reset Functions,

Check Safeguard Functions,

Check Input Functions,

Check Output Functions,

Check Robot Mounting Screws

Refer to 4.2.1.5 Robot Arm Installation

EMO button (SEMI version only)

Press the EMO button to check whether

power has been switched off.

Table 19: Summary of the Preventive Maintenance Procedures and Guidelines

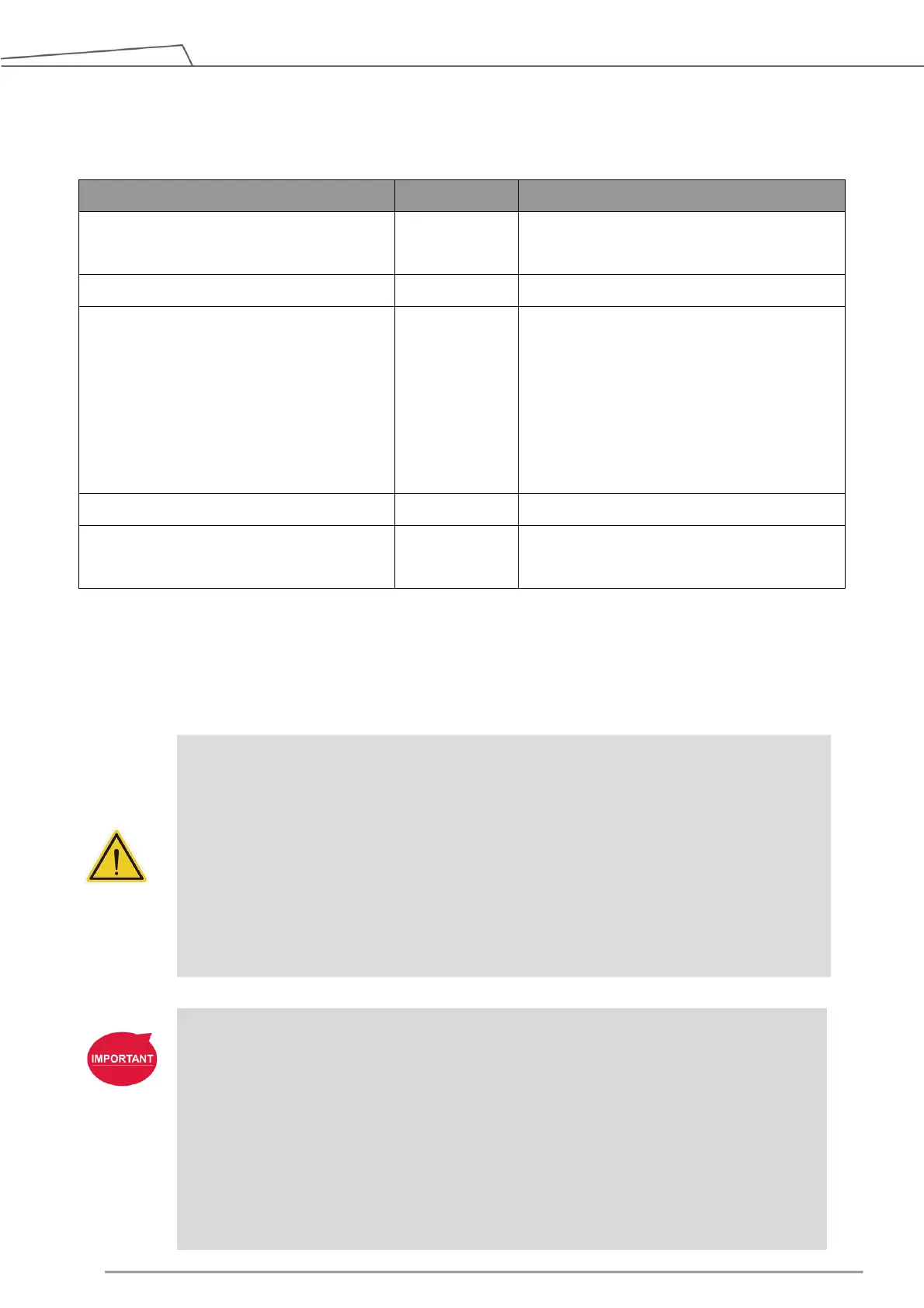

Only the legal distributor or authorized service center should repair the TM Robot. Users should not repair it by

themselves.

IMPORTANT:

After the maintenance is completed (including the change of component parts or addition of

optional equipment for both hardware and software to the robot), make sure all the tests

and examination listed below are carried out:

1. The functional testing of Emergency Stop functions

2. The functional testing of Safeguard functions

3. The functional testing of Enabling Switch functions

4. The functional testing of Force and Torque Limit functions

5. The functional testing of Speed Limit functions

6. The functional testing of Soft Axis Limit functions

DANGER:

Before performing maintenance or service record the details of each setting for the robot for

normal operation. Make sure that each setting satisfies the original conditions before

resuming normal operation, including but not limited to:

Safety Software Settings

Safety I/O

Preset operation project

TCP Settings

I/O Settings

I/O Wiring

Loading...

Loading...