Remote Radiator (Optional)

Remote radiators can be located a horizontal or a

verti-

cal distance, from an engine. The horizontal distance is

limited by the capability of the engine driven water pump

and the maximum external Friction Head pressure. The

vertical distance is limited to the maximum Static Head

pressure which can be imposed on coolant system

gaskets and seals without leakage of coolant from coo-

lant system components. The Friction and Static Head

pressures of each GenSet are included in their Product

Data Sheet.

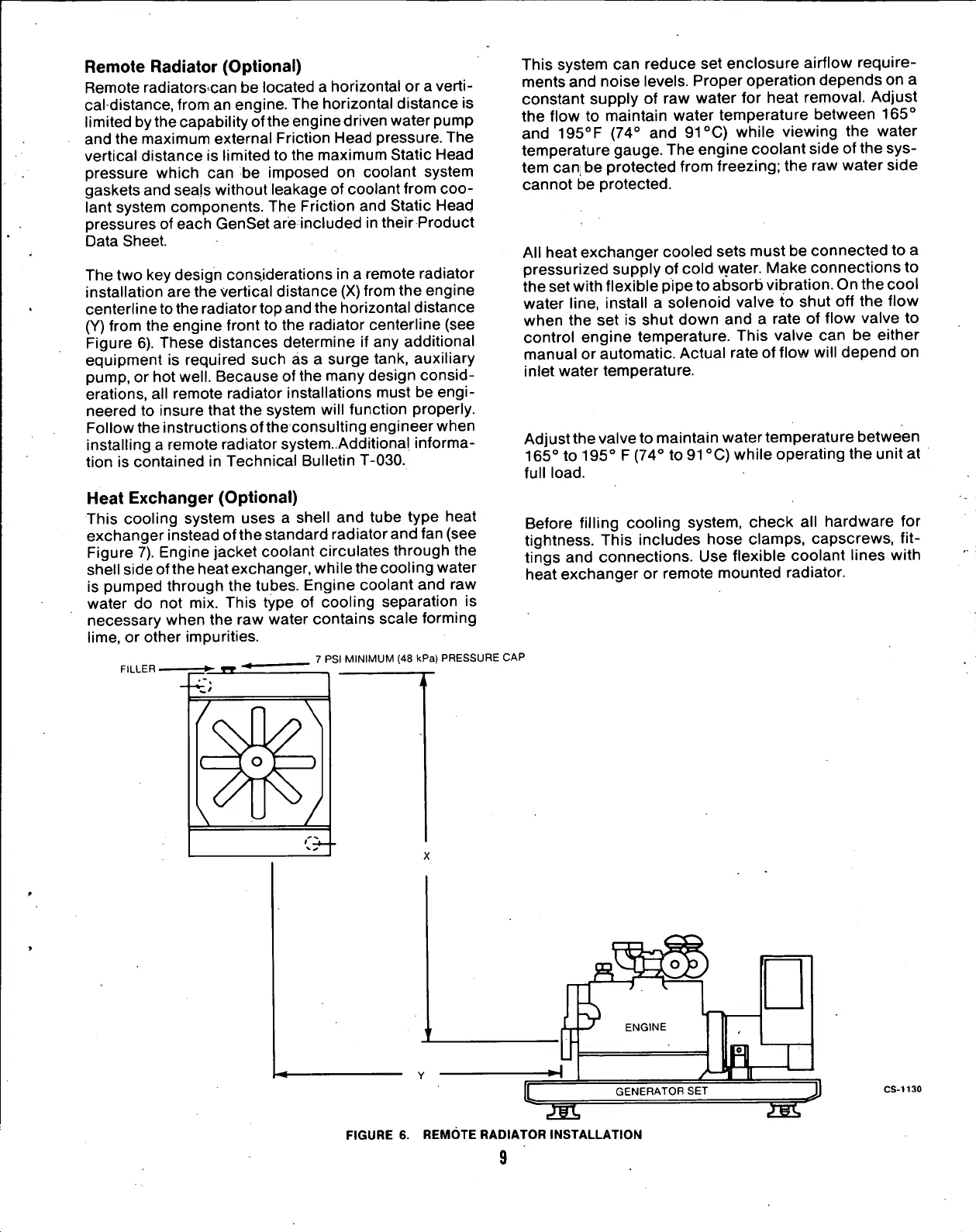

The two key design considerations in a remote radiator

installation are the vertical distance (X) from the engine

centerline to the radiator top and the horizontal distance

(Y)

from the engine front to the radiator centerline (see

Figure 6). These distances determine if any additional

equipment is required such as a surge tank, auxiliary

pump,

or hot

well.

Because of the many design consid-

erations, all remote radiator installations must be

engi-

neered to insure that the system will function properly.

Follow the instructions of the consulting engineer when

installing a remote radiator system-Additional informa-

tion is contained in Technical Bulletin T-030.

This system can reduce set enclosure airflow require-

ments and noise levels. Proper operation depends on a

constant supply of raw water for heat removal. Adjust

the flow to maintain water temperature between 165°

and 195

0

F (74° and 91

0

C) while viewing the water

temperature gauge. The engine coolant side of the sys-

tem can be protected from freezing; the raw water side

cannot be protected.

All heat exchanger cooled sets must be connected to a

pressurized supply of cold water. Make connections to

the set with flexible pipe to absorb vibration. On the cool

water line, install a solenoid valve to shut off the flow

when the set is shut down and a rate of flow valve to

control engine temperature. This valve can be either

manual or automatic. Actual rate of flow will depend on

inlet water temperature.

Adjust the valve to maintain water temperature between

165° to 195° F (74° to 91

0

C) while operating the unit at

full

load.

Heat

Exchanger

(Optional)

This cooling system uses a shell and tube type heat

exchanger instead ofthe standard radiator and fan (see

Figure 7). Engine jacket coolant circulates through the

shell side ofthe heat exchanger, while the cooling water

is pumped through the tubes. Engine coolant and raw

water do not mix. This type of cooling separation is

necessary when the raw water contains scale forming

lime,

or other impurities.

7 PSI MINIMUM (48 kPa) PRESSURE CAP

FILLER

Before filling cooling system, check all hardware for

tightness. This includes hose clamps, capscrews, fit-

tings and connections. Use flexible coolant lines with

heat exchanger or remote mounted radiator.

C

ENGINE

GENERATOR SET

m

FIGURE 6. REMOTE RADIATOR INSTALLATION

9

CS-1130

Loading...

Loading...