!

ASSETNBTY

TORQUES

AND SPECIAT

TOOTS

TORQUE

Assembly torques as

given

here require the

use

of a

torque wrench. These assembly torques will assure

proper tightness without

danger

of

stripping the

threads.

If

a torque lvrench is not

available, you will

have to

estimate the degree of tightness necessary

for

the

stud,

nut

or

screw

being installed

and tighten accordingly.

Be

careful

not

to strip the threads.

Check all studs,

nuts

and

screws

often

with

the

engine cold. Tighten as

needed to

prevent

them

frorn working loose.

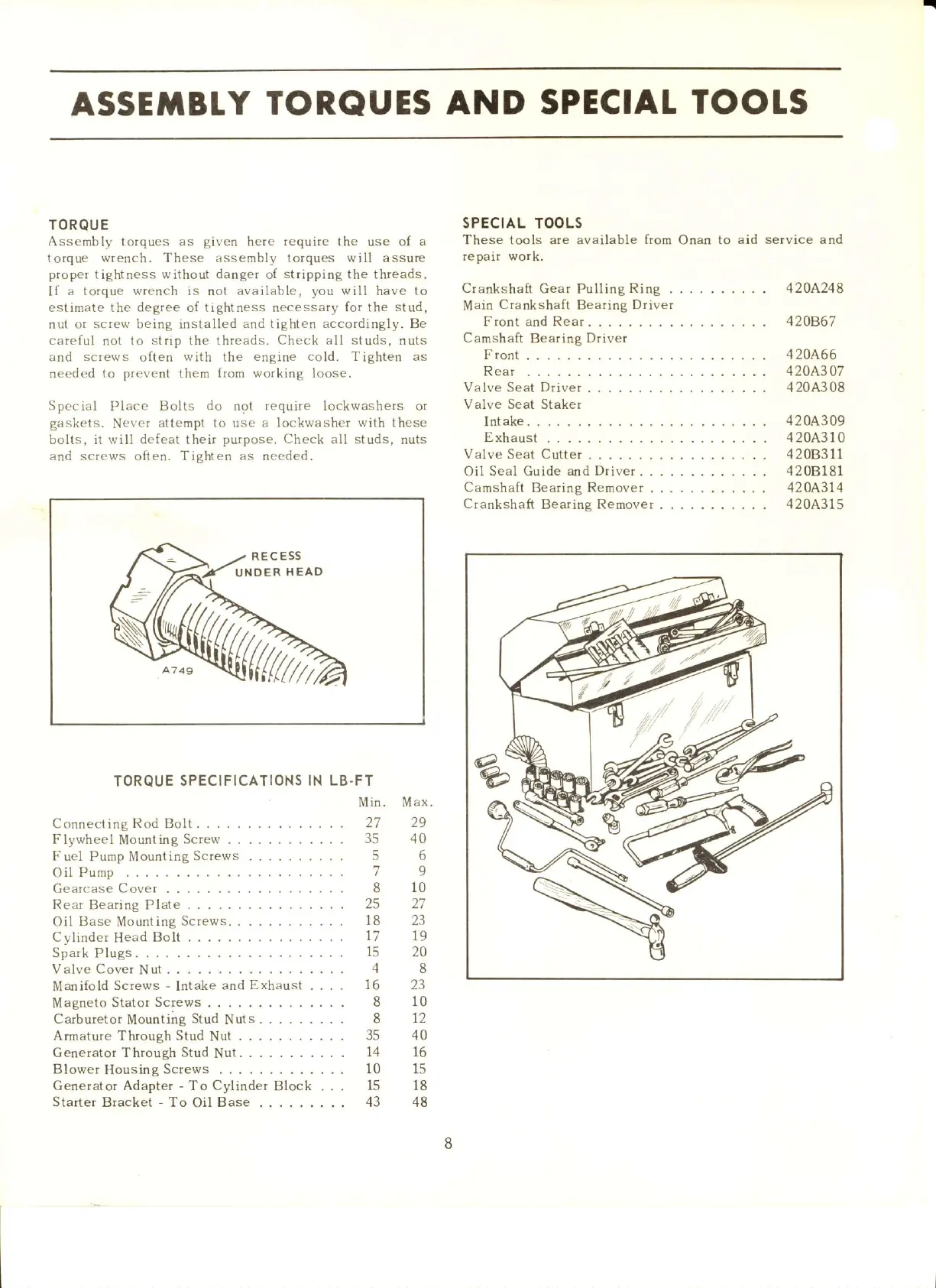

Special

Place

Bolts

do

not

require

lockwashers or

gaskets.

Never

attempt

to use

a lockwasher with these

bolts, it will defeat their

purpose. Check all studs,

nuts

and screws often. Tighten as needed.

R€ C

ESS

UNDER

HEAD

TOROUE

SPECIFICATIONS IN LB-FT

SPECIAL

TOOLS

These tools

are available from

Onan

to aid

repair work.

Crankshaft

Gear PullingRing .... .....

Main

Crankshaft

Bearing

Driver

Front and

Rear

.

Camshaft

Bearing

Driver

Ftont..

Rear

Valve Seat

Driver

.

Valve Seat Staker

Intake.

. .

Exhaust

service and

. 420A248

.

420867

.

420A66

.

420A307

. 42043 08

.

420A3

09

.

4 20A310

.

4 208311

.

4

2 08181

.

420A314

.

420A315

Valve Seat Cutter

.

Oil

Seal

Guide

and Driver.

. . .

Camshaft

Bearing

Remover

. .

Crankshaft

Bearing Remover .

.

.

C onnect ing

Rod

Bolt

FlywheelMountingsctew ..........

F ur-l

Pump [lounting

Screws

Oil

Pump

Ccarcase

Cover

Ii(.ar Beaong

PIate

..

Oil

Base

l\4odnl

Ing Screws.

CylinderHeadBolt....

Spark Plugs.

V alve Cover

N

ut .

Manifold

Screws

-

lotake

and

Exhaust

. .

Magneto

Stator

Screws

. .

Carbureror

Moun

t ing Stud

Nuts

Armature Through

Stud

Nur

,

Generator Through Stud

Nut..

.. .....

Blower

H ousrn

g

Screws

Generator Adapter

-

To Cylindet Block

. . .

Starter

Bracket

-

To

Oil

Base

>

'/e-4

Min.

Max.

27 29

35

40

56

79

8

10

25 27

18 23

17 19

15

20

48

16 23

8

10

812

35 40

74 16

10 15

15 18

43 48

Loading...

Loading...