!

CARBURETOR

ADJUsTMENT

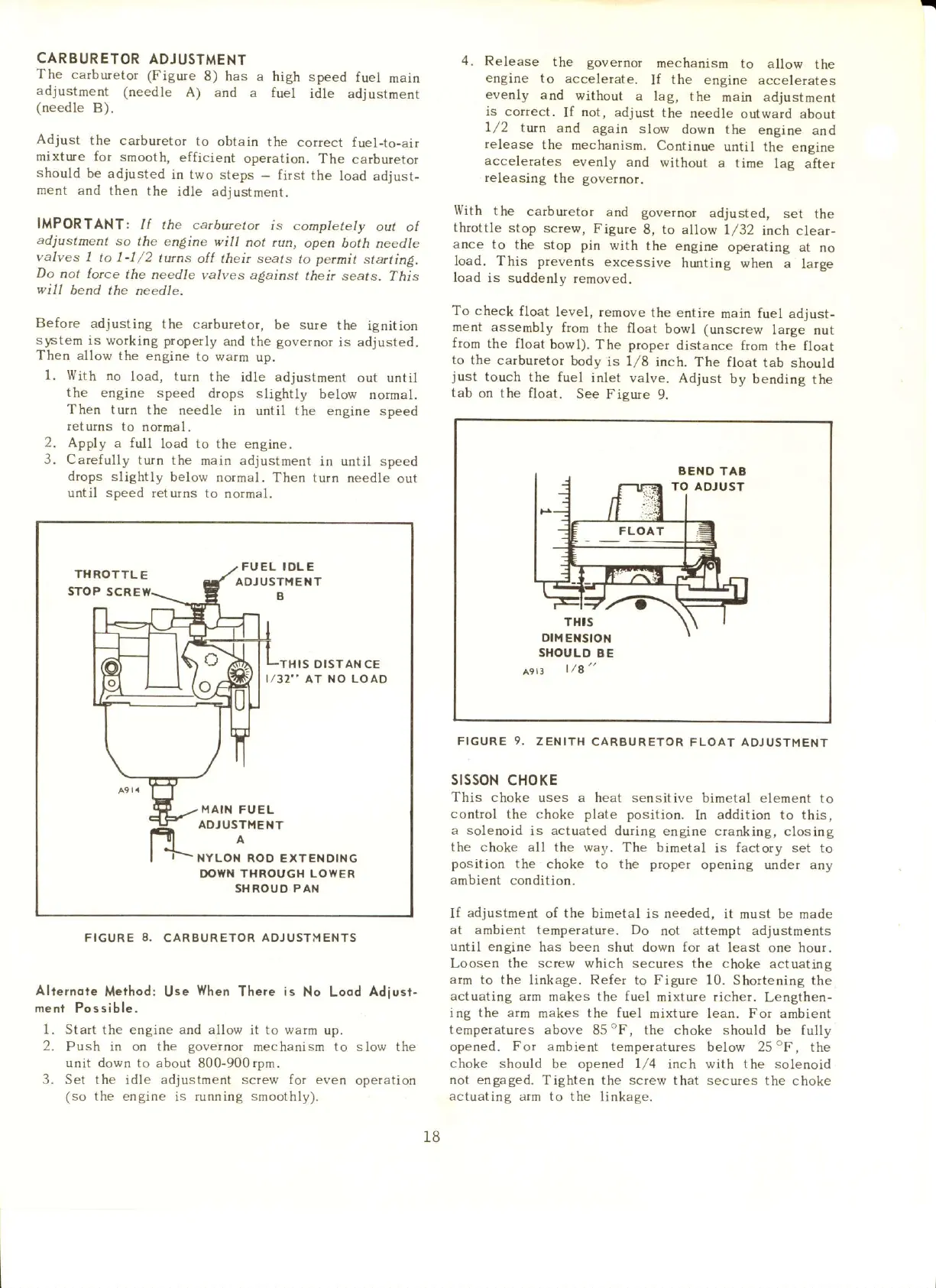

The

carburetor

(Figuie

8) has

a high

speed fuel

main

adjustment

(needle

A)

and a fuel

idle adjustment

(needle

B).

Adjust

the calburetor

to

obtain

the corfect fuel-to-air

mixture for

smooth,

efficient

operation.

The

carburetor

should

be adjusted

in two steps

-

first

the load

adjust-

ment

and then

the idle

adjustment.

IMPORTANT;

II the carburetot

is completely

out ol

adjustment

so

tfie enlline

will

not tun,

open both

needle

valves 1

to 1-1/2

tutns

otl

their

seats

to permit

starting.

Do

not force

the needle

yalyes

a{ainsf

tleir seats.

Tfiis

will

bend the

needle.

Before adjusting

the

carburetor,

be sure the

ignition

s],stem

is working properly

and

the

governor

is adjusted.

Then

allow the engine

to

warm up.

1.

With no

load, turn

the

idle

adjustment

out until

the

engine

speed

drops slightly

below

normal.

Then

turn the

needle

in until the engine

speed

retums

to normal.

2. Apply

a full

load to the ergine.

3. Carefully

turn

the main adjustmeot

in

until speed

drops slightly

below

normal. Then

turn needle

out

until speed returns

to normal.

THROTTL

E

STOP

SCRE

THIS

OISTAN CE

t/32"

AT

NO LOAO

MAIN

FUEL

AOJUSTTIE

NT

YLO ROO EXTENDIXG

DOWX THROUGH LOIVER

SHROUO PAN

FIGURE

8.

CARBURETOR

ADJ

USTM

ENTS

Alternote

Method: Use

When

There is

No Lood

Adiust-

rnent

Pos

sible.

1. Start the engine and allow

it to

warm

up.

2.

Push in on the

governor

mechanism to slow the

unit

down

to about 800-900rpm.

3. Set the idle adjustrnedt screw for even

operation

(so the engine

is

running smoothly).

4.

Release

the governor

mechanism

to

allow

the

engifle

to accelerate.

If

the

engine accelerates

evenly

and

without

a

lag, the

main adjustment

is correct.

If

not,

adjust the

needle

outward

about

l/2 tltn

and

again

slow

down the

engine

and

release

the rnechanism.

Continue

until the

ensine

accelerates

evenly

and

without

a tirne

lag after

releasing

the governor.

With

the

carburetor

and governor

adjusted,

set the

throttle

stop screw,

Figure

8, to

allow 1/32

inch clear-

ance

to the stop pin

with the

engine

operating

at no

load, This prevents

excessive

hunting

when

a large

Ioad is

suddenly

removed.

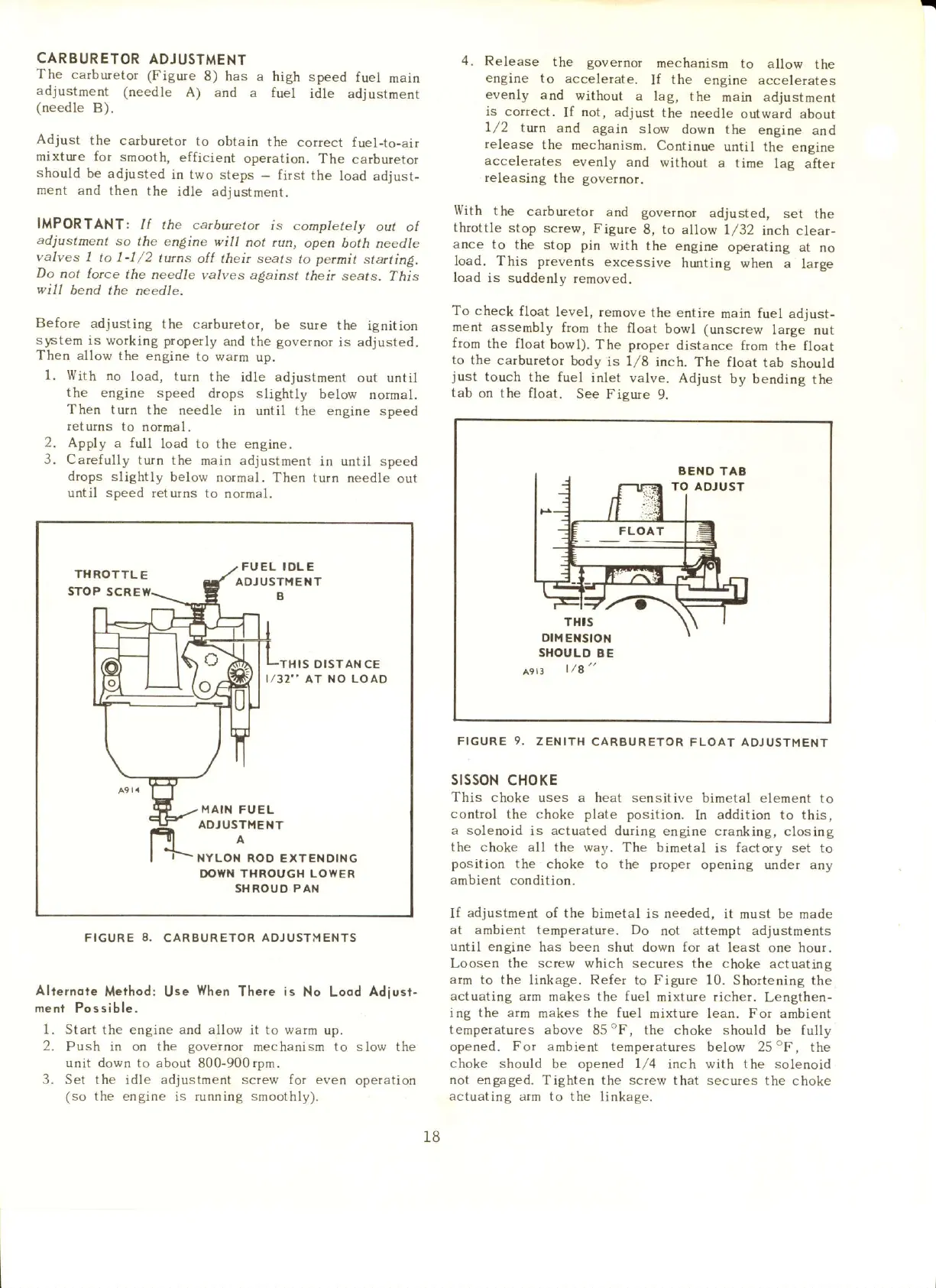

To check

float

level, femove

the

entire

main fuel

adjust-

ment

assembly

ftom

the

float bowl (unscrew

large nut

from

the float

bowl).

The

proper

distance

ftom the float

to

the carburetor

body

is

1/8

inch,

The float

tab should

just

touch

the fuel

inlet valve.

Adjust

by bending

the

tab

on the float.

See

Fieure

9.

SI{OULD

B E

A9rr

|/a"

FIGURE

9.

ZENITH

CARSURETOR

FLOAT

AOJUSTMENT

stssoN

cHoKE

This choke

uses a heat sensitive

bimetal element to

control

the

choke plate

position.

In

addition to this,

a solenoid

is actuated duting engine

cranking, closing

the

choke all the way. The

bimetal is factory set to

position

the choke to the proper

opening

under

any

ambient

condition,

If

adjustment

of the bimetal is needed,

it must be made

at ambient temperature. Do

oot

attempt adjustments

until

engine has been shut down for

at least

one

hour.

Loosen the

screw

which secures the choke

actuating

arm

to

the

linkage. Refer to Figure 10.

Shortening the

actuating

arm makes the fuel

mixture

richer.

Lengthen-

ing the arrn makes the fuel

mixture lean. For ambient

temperatufes above

85"F, the choke should

be fully

opened. For ambient temperatures

below 25"F, the

choke

should

be opened

l/4

inch with the solenoid

not engaged.

Tighten the screw that secures

the choke

actuating aim to

the linkage.

18

Loading...

Loading...