I

ADJUSTTIENTS

GEN

ERAL

Satisfactory engine

performance

is largely dependent

upon corect adjustments.

However,

adjustments

can-

not fully compensate

for

low

engine

powet

due to wear,

etc.

If

ttouble

develops, follow an

orderly

procedure

to determine the cause

before

making

any adjustment.

Refer to the Troubleshooting

Chart for help in checking

causes of

troubles which

may occur,

BREAKER

POINTS

1. Remove the

two

screws and the cover

on

the

breaker box.

2. Remove the

two

spark

plugs

so

engine

can be

easily rotated by hand.

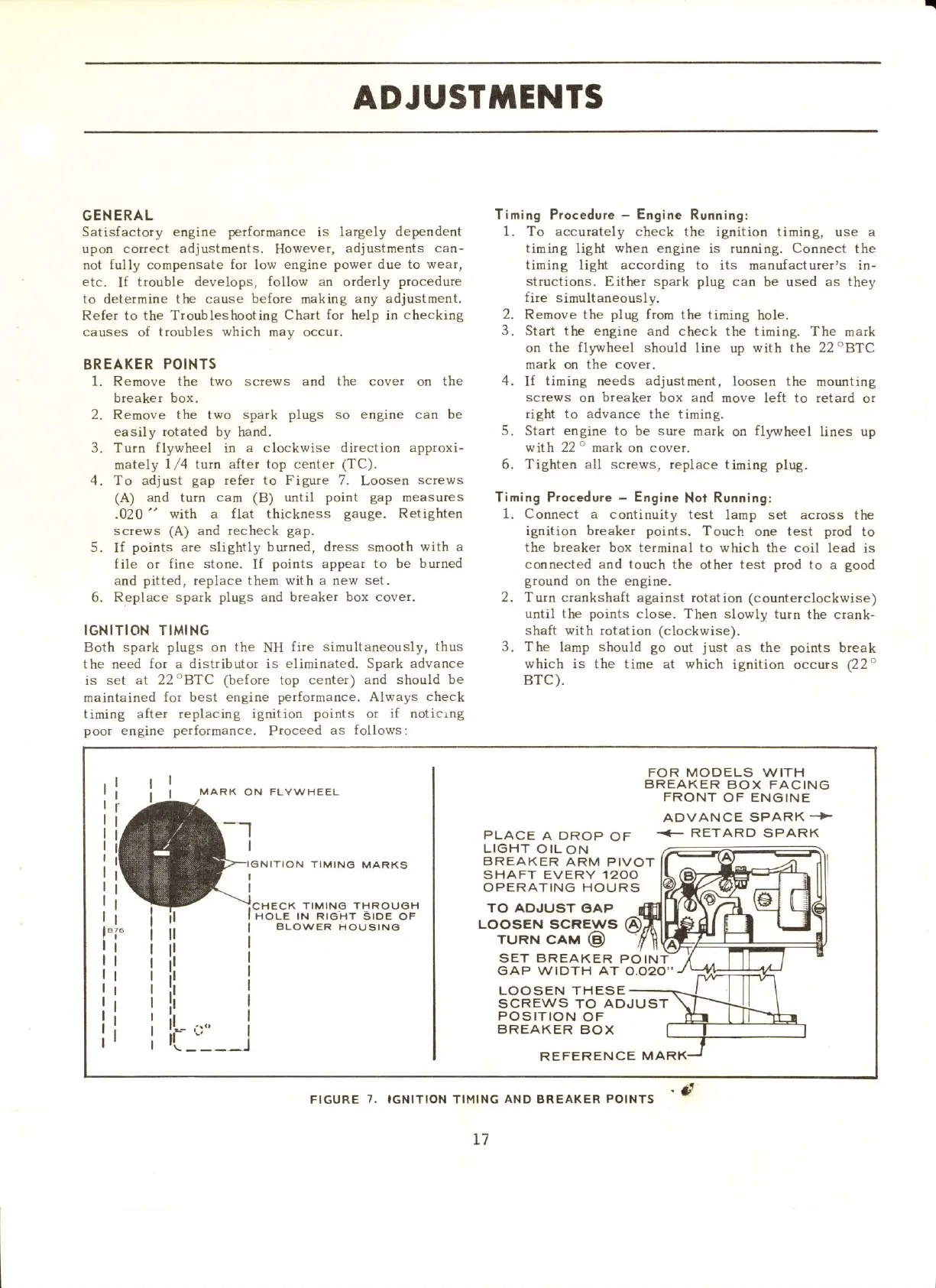

3. Turn

flywheel

in

a clockwise direction approxi-

mately

1/4 turn after top center (TC).

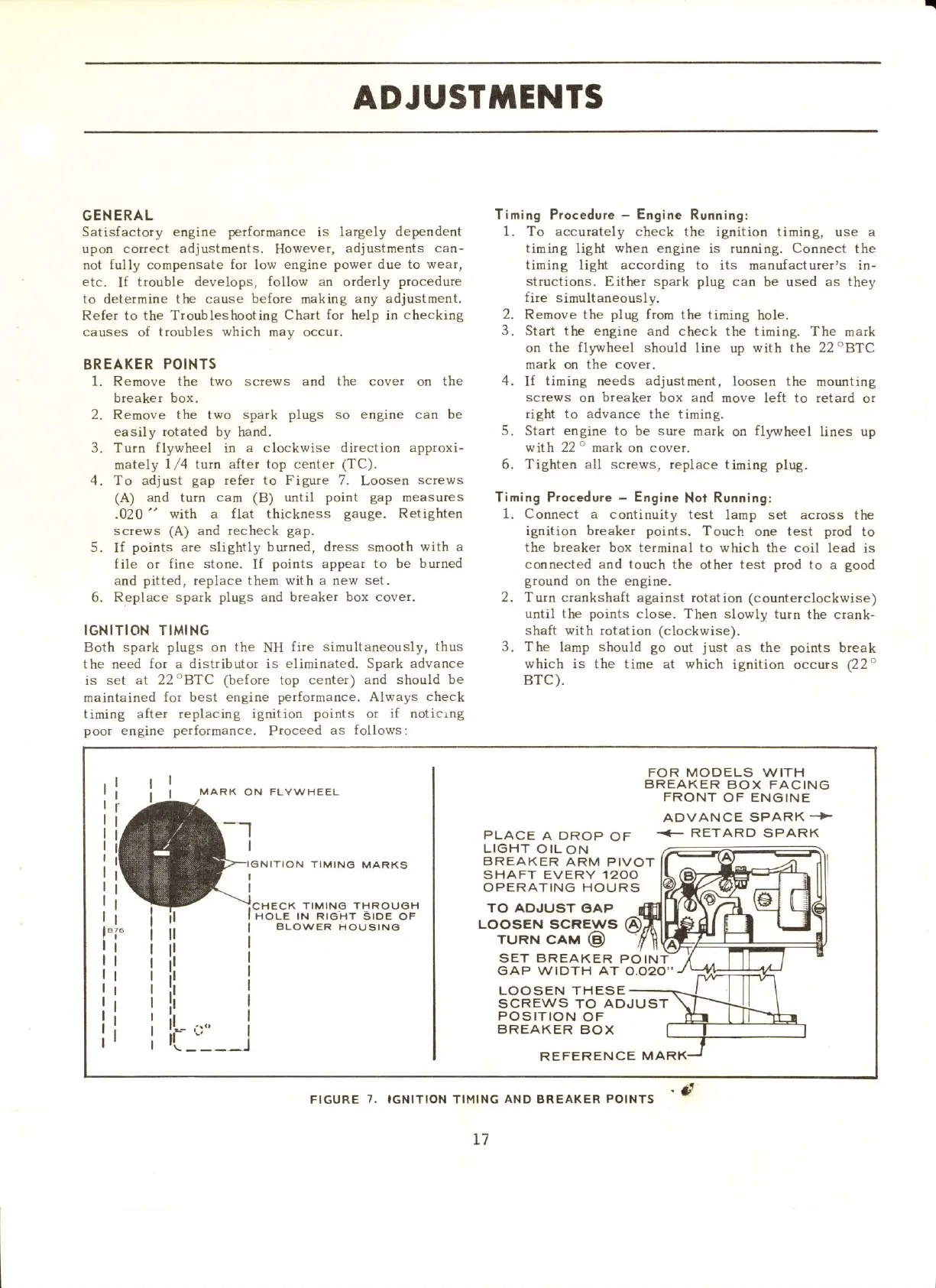

4. To adjust

gap refer to Figure 7,

Loosen

screws

(A)

and

turn

cam (B) until

point gap

measures

.020

"

with a flat thickness

gauge.

Retighten

screws

(A)

and

recheck

gap.

5.

If

points

are slightly

butned, dress smooth with a

file

or

fine stone.

If

points

appear to be

burned

and

pitted, replace them with a new set.

6.

Replace spark plugs and breaker box cover.

IGNITION TIMING

Both spark

plugs

on

the

NH

fire simultaneously, thus

the need for a distributor is

eliminated. Spark advance

is set

at 22oBTC (before top center) and

should be

maintained

for best engine performance. Always

check

timing after replacing

ignition

points

or if noticrog

poot

engine

performance.

Ptoceed

as follows:

Timing Procedure

-

Engine

Running:

1. To accurately

check the ignition timing, use a

tirning light when engine is running. Connect

the

timing light accotding to

its manufacturer's in-

structions.

Either spark

plug

calr

be used

as they

fite

simultaneously.

2. Remove the

plug

from

the timing hole.

3.

Start the engine and

check the timing. The

mark

on

the fllnvheel should

line up with the 22oBTC

mark on the cover.

4.

If

timing oeeds

adjustment,

loosen the

mourting

screws

on breaker box arrd

move left to retard

or

right

to

advance the timing.

5.

Start

engine

to be sure mark

on

fltmheel

lines up

wfth 22o mark on cover.

6.

Tighten all screws,

replace tirning

plug,

Timing Procedure

-

Engine

Not

Running:

1. Connect

a continuity test

lamp set acrcss the

ignition breaker points.

Touch one test

prod

to

the breaker box

terminal to which the coil

lead is

connected and touch the

other

test piod

to a

good

ground

or! the engine.

2. Turn crankshaft against rotation

(counterclockwise)

until the

points

close. Then slowly turn

the crank'

shaft with rotation (clockwise).

3. The

lamp

should go

out

just

as the points

break

which is the time at which

ignition

occurs

(22"

BTC).

I

I

t

I

MAFIK

ON FLYW HEEL

FOR

MODELS WITH

BREAKER

BOX FACING

FRONT

OF

ENGINE

ADVANCE SPARK

..>

OF

<- RETARD SPARK

--1

PLACE

A DROP

LIGHT

OILON

N TIMING

MARKS

BRE,AKER

ARM

PIVOT

SHAFT EVERY

,I2OO

OPERATING HOURS

ll

ll

tl

it

ii

il

..,,

rr:_'_

TO

ADJUST

OAP

LOOSEN

SCREWS

TURN

CAM

@

SET

BREAKER

GAP WIOTH AT

POI

o.o20"

LOOSEN THESE

SCREWS

TO ADJUST

_)

POSITION

OF

BREAKER

BOX

REFERENCE

MARK

FIGURE

7.

IGNITION TIMING

AND

BREAKER

POINTS

.

d

T7

Loading...

Loading...