!

9. Wipe

entire unit.

Coat rustable

parts

with

a light

film of

grease or oil.

10.

If

battery is used,

disconoect and

follow standard

battery

storage

procedure.

DUST

AND DIRT

l.

Keep

plant clean.

Keep

cooling surfaces clean.

2. Service air cleaner as

frequently as necessary.

3. Change crankcase oil every

50

operating

hours

or

sooncr.

4.

Kcep

oil

and

gasoline

in

dust-tight

containers.

5.

Keep

governor

linkage

clean.

6.

Clean

generator

btushes,

slip

rings

and commutatot.

Do

nol remove normal

(dark btown) film.

Do

oot

pol

ish.

HIGH

ALTITUD E

For operation

at altitudes

of

2500 feet above sea level,

close

carburetor main

jet

adjustment slightly

to

main-

tain

proper

air-to-fuel

ratio (refet to the

ADJUSTMENT

SECTION), Maximum

power

will be

reduced approxi-

mately 4%

for

each

1000 feet above sea level, after lhe

first

1000 feet.

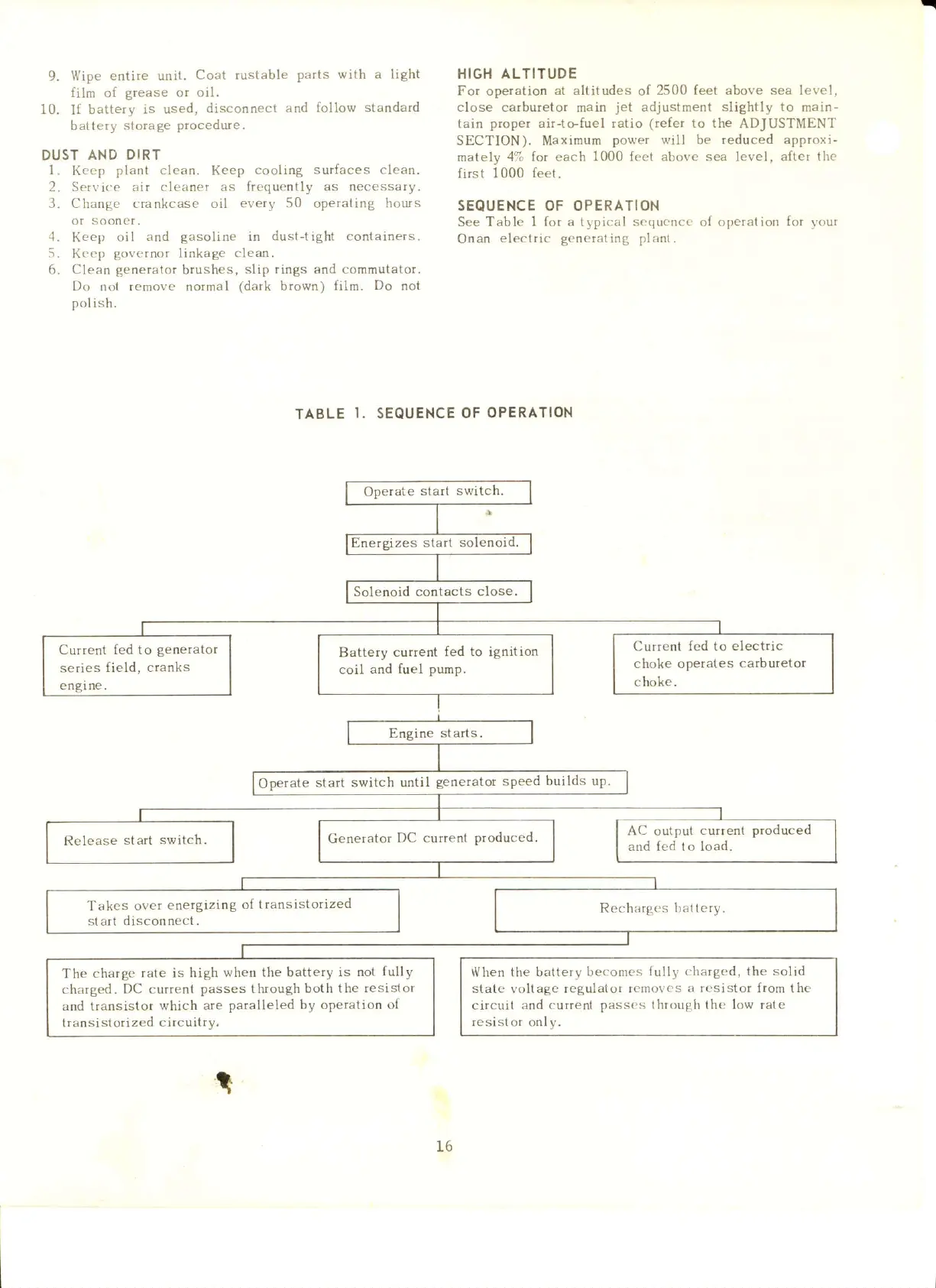

SEQUENCE OF OP

E RATION

See Table

1 for a

typical

sequcnc{:

of

operation for your

Onan

electtic generating plant.

TABLE

I.

SEQUENCE

OF OPERATION

Operate

starl swr tch.

Energizes

statt so

Solenoid cofltacts

close,

Battery

current fed

to

ignition

coil and

fuel

pump.

Current fed to

electlic

choke operates

carbuletor

choke.

Current

fed to

generator

series

field, cranks

englne.

Operate

start switch until

ge$eiator speed

builds

up.

Generator

DC cunent

produced.

AC output

current ptoduced

and fed to load.

Release

start

switch.

Recharges

baltery.

Takes

over

energizing

of trarlsistorized

st art

disconnect.

The

charge

rate is high

when the battery is

not

fully

charged.

DC

current

passes

tluough

both the

resistor

and

transistor

which are

paralleled by operation of

transistorized

circuitry.

When the battery

becomcs

fully charged, the solid

state

voltage

regulator removcs

a resistor

ftom the

circuit

and current passes through the low rate

tesrslor onl y.

!

l6

Loading...

Loading...