I

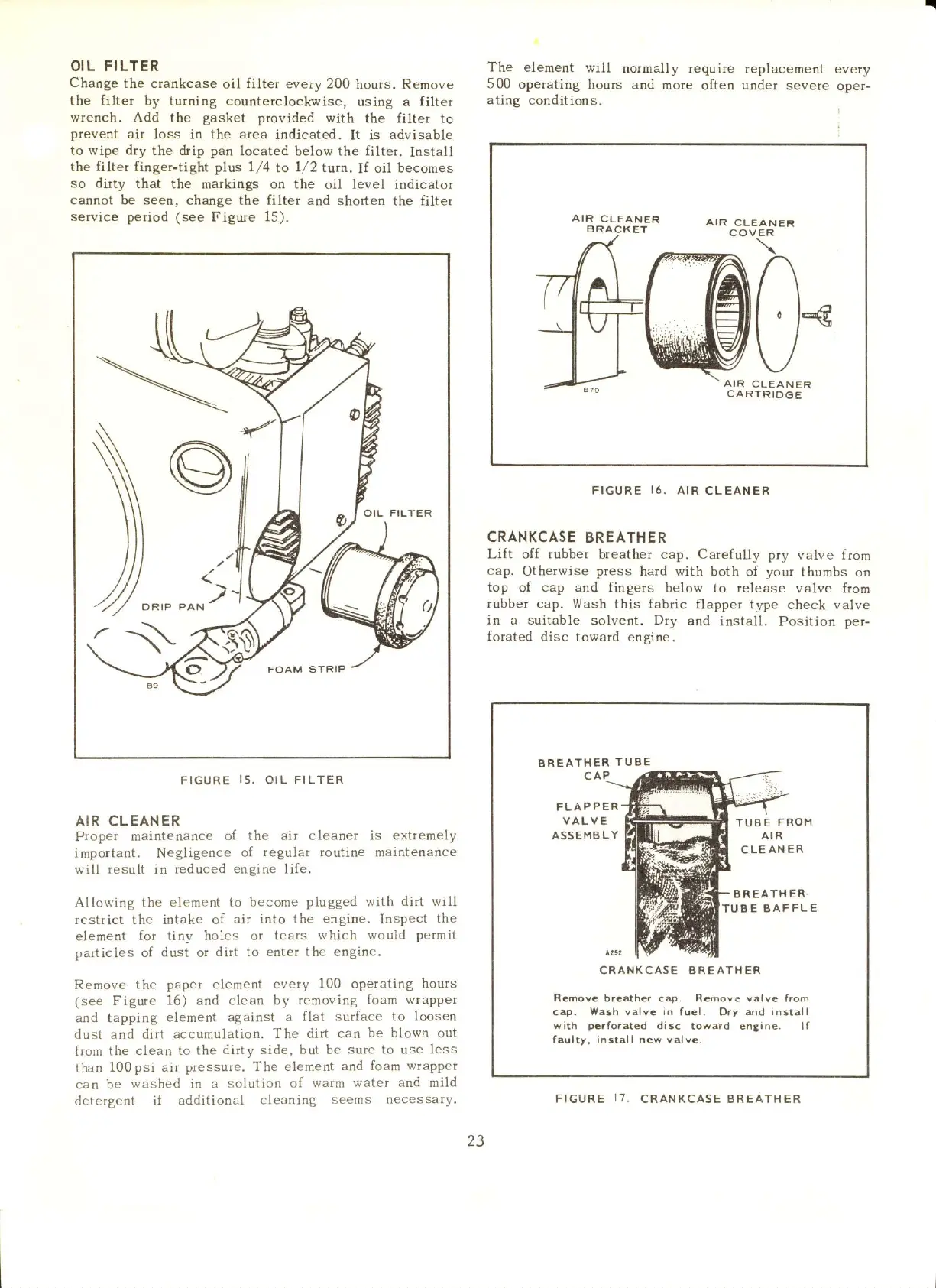

OIL FILTER

Change

the crankcase

oil

filter

every 200

hours. Remove

the filter

by turning counterclockwise,

using a

filter

wrench. Add

the

gasket

provided

with

the filter to

prevent

air

loss in

the area

indicated.

It is

advisable

to wipe dry

the

drip pan

located below the filter.

lnstall

the

filter

finger-tight plus 1/4

to

l/2

tnrf,.

ll

oil becomes

so dirty

that the maikings on the

oil

level

indicator

cannot be seen,

change the

filter

and shorten

the filter

service period (see

Figure 15).

OIL

FILTER

FIGURE

I5.

OIL F ILTER

AIR

CLEANER

Proper maintenance

of the air cleaner

is exttemely

important.

Negligence

of

regular routine

maintenance

will

result

in

reduced engine life.

Allowing

the element to

become

plugged

with

dirt will

restrict the intake of

air into the

engine.

Ilspect

the

element

for tiny

holes

or

tears

which would

permit

particles

of dust or

dirt to enter the engine.

Remove the

paper element

every

100

operating

hours

(see

Figure

16)

and

clean by temoving

foam wtapper

and tapping

element agailst

a flat

surface to loosen

dust and

dirt accumulation.

The dirt can

be blown out

from the

clean to the

dirty side, but be

sure to use less

than

100psi air pressure.

The element

and foam wrapper

can be

washed

in

a solution

of warm

water and mild

detergent

if additional

cleaning

seems

necessaty.

The element

will

normally require

500

operating hous and

more

often

ating

conditioris,

replacement

every

under

severe

oper-

FIGU R E

I6.

AIR

CLEANER

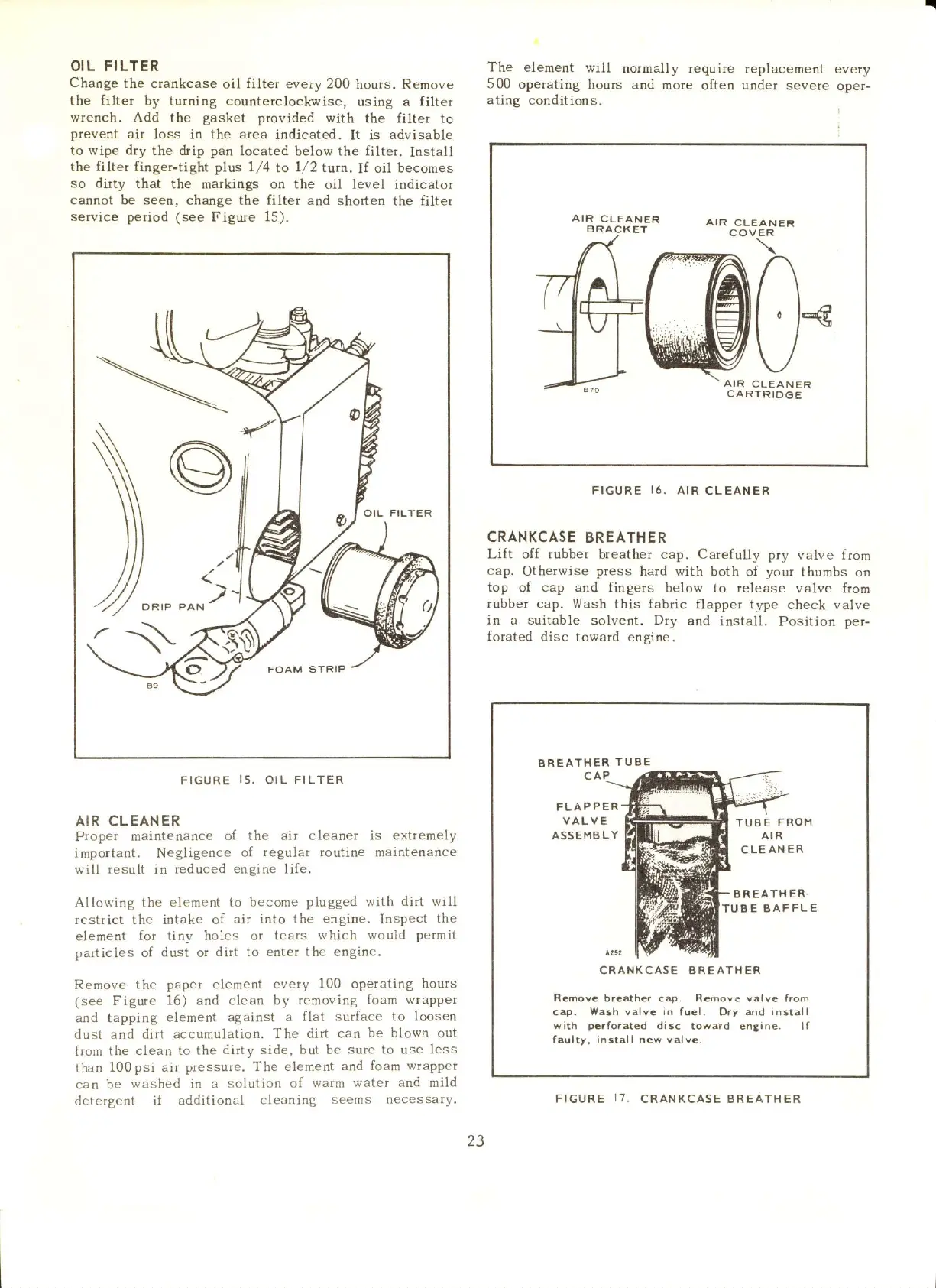

CRANKCASE

BREATH ER

Lift off rubber

breather cap. Carefully pry

valve from

cap.

Otherwise

press

hard with

both of your thumbs

on

top

of cap and fingers

below to release valve

f.om

rubber cap.

Wash this fabric flapper

type check valve

in a suitable

solvent.

Dty

and

install.

Position

per-

forated

disc

toward enqine.

AIR

CLEANER

COVER

A

I'l-€

V

AIR

CLEANER

CARlRIDGE

B R

E

ATHER

TUBE

CAP

FLAPPER

ASSEHB LY

TUBE

FROM

AIR

CLEATI€R

BREATHER'

TUBE BAFFLE

CRANKCASE

AREATH ER

Rcmovc

brcather cap. R€move valve trom

cap.

lYach valvc In

fuel. Ory

and install

with

pcrforated

disc

toward entane.

lf

faulty, install ncw valve.

23

FIGURE

I7.

C RAN KCASE BREATHER

Loading...

Loading...