!

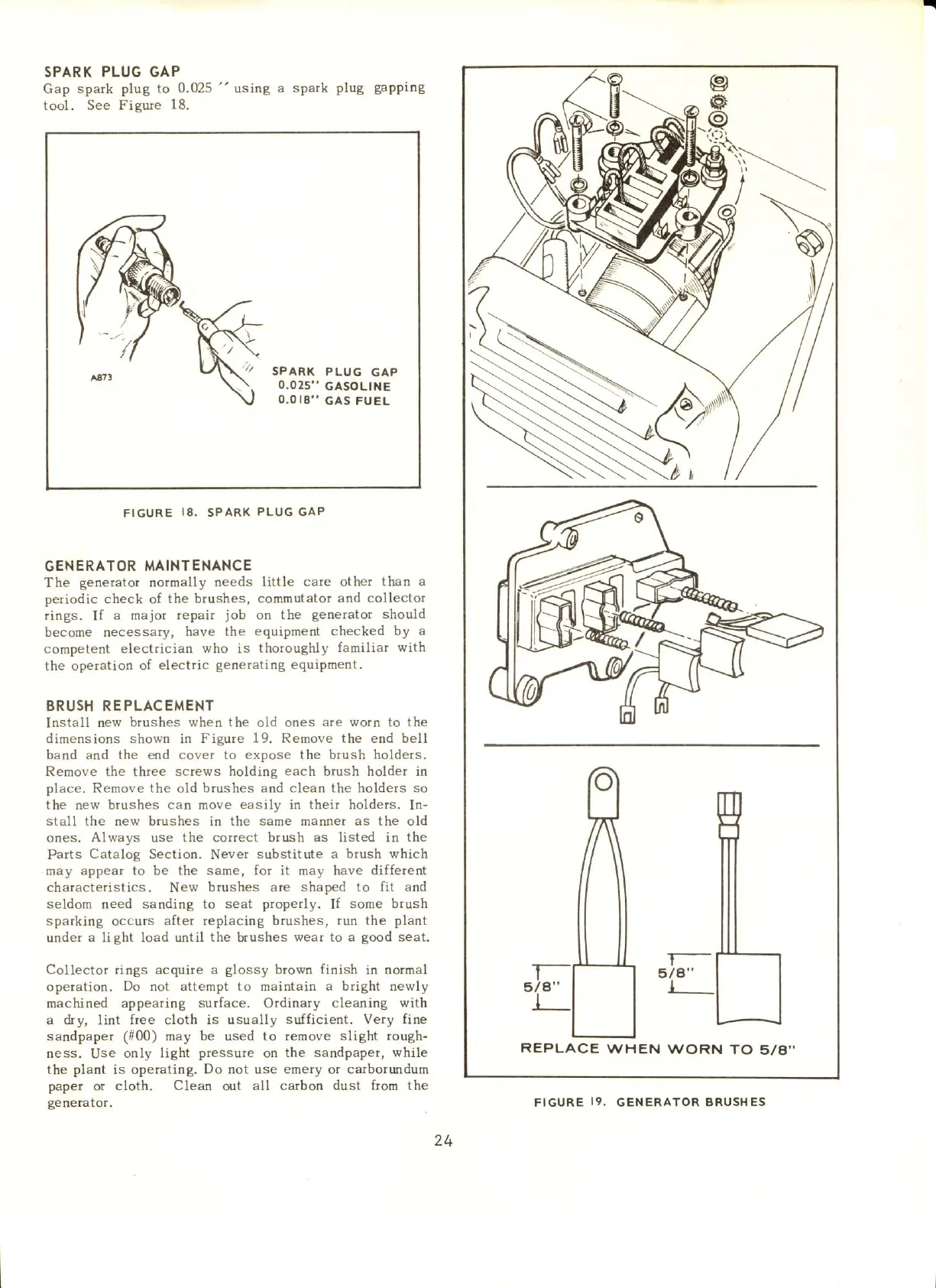

SPARK

PLUG

GAP

Gap spark

plug

to

0.025

"

using a

spark

plug

gapPing

tool. See Fieure

18.

SPARK

PLUG

GAP

0.02s"

GASOLTNE

0.0

18"

GAS

FUEL

FIGURE

18.

SPARK

PLUG GAP

GENERATOR

MAINTENANCE

The

generator

normally

needs little

cate

other

than a

petiodic check of

the brushes, commutator

and collector

rings.

If

a major repai!

job

on

the

generator should

become necessary,

have the

equipment checked by a

competent electrician

who

is

thoroughly

familiar with

the operation of

electric

generating

equipment.

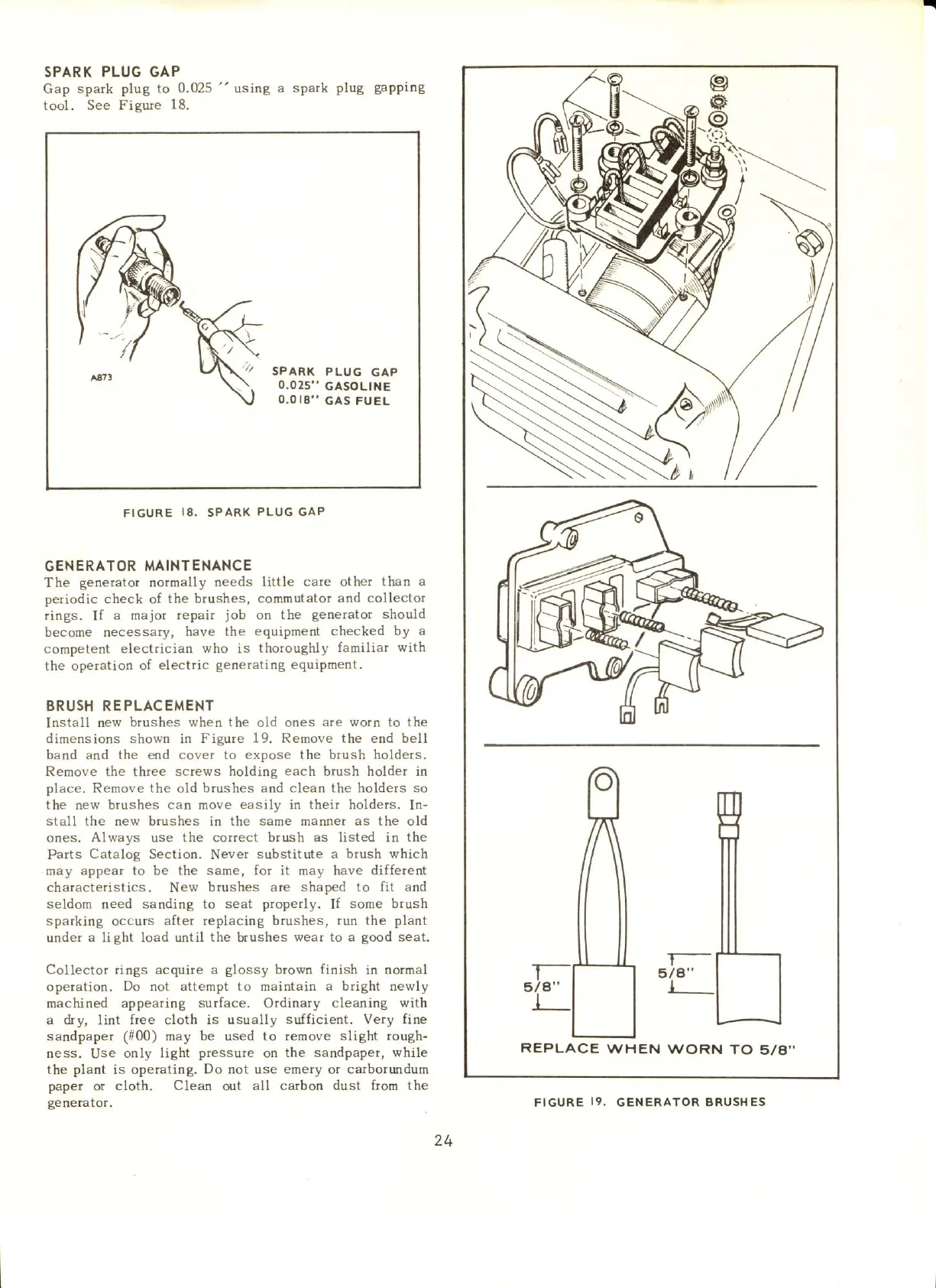

BRUSH

RE PLAC EMENT

Install

trew brushes when the o1d ones

are

worn

to the

dimensions shown

in

Figute 19. Remove the end bell

band and the end cover to expose the brush holders.

Remove the

three

screws holding each brush holder in

place.

Remove

the

old

brushes

and

clean the holders so

the new brushes can move

easily in their

holders. In-

stall

the rlew

brushes

in

the same manner as the

old

ones.

Always use the correct brush

as

listed in

the

Parts

Catalog

Section. Never

substitute a brush which

may appear to be the same, for it may have diffetent

ch aracteri st ics , New

brushes are shaped to fit and

seldom need salding to seat

pfoperly.

If

some

brush

sparking occurs after replacing

brushes, run the

plant

under

a

light load until

the

brushes

wear to a

good

seat.

Collector rings

acquire

a

glossy

btown finish

in

normal

operation.

Do

not attempt to maintain

a bright newly

machined

appearing surface. Otdinary cleanirtg

with

a dry, lint

free

cloth

is usually sufficient. Very

fine

sandpaper (#00) may be used to remove slight

rough-

ness.

Use

only light

pressure

on

the sandpaper, while

the

plant

is operating.

Do not use emery

or

catborundum

paper

or

cloth. Clean

out

all carbon

dust from

the

generator.

e

*

@

[\,

'\\

t

------

//

REPLACE

\^r'HEN WORN

TO

5/A''

L.+

FIGURE

I9.

GENERATOR

BRUSHES

Loading...

Loading...