- 48 –

18-06-08 PVD3668_GB_GVM_June_2018

3.4. Motor mounting

3.4.1. Motor mounting environment

Ideally mount motors:

In a location away from, or shielded from other vehicle heat sources such as exhaust,

or catalytic converters etc.

In a location that will benefit from air flow while the vehicle is in motion.

In location that is protected from flying rocks, debris, road salt, or other contaminants

that could damage cabling and connections.

3.4.2. Motor mounting

For the screws tightening torque values, please see the board on page 61.

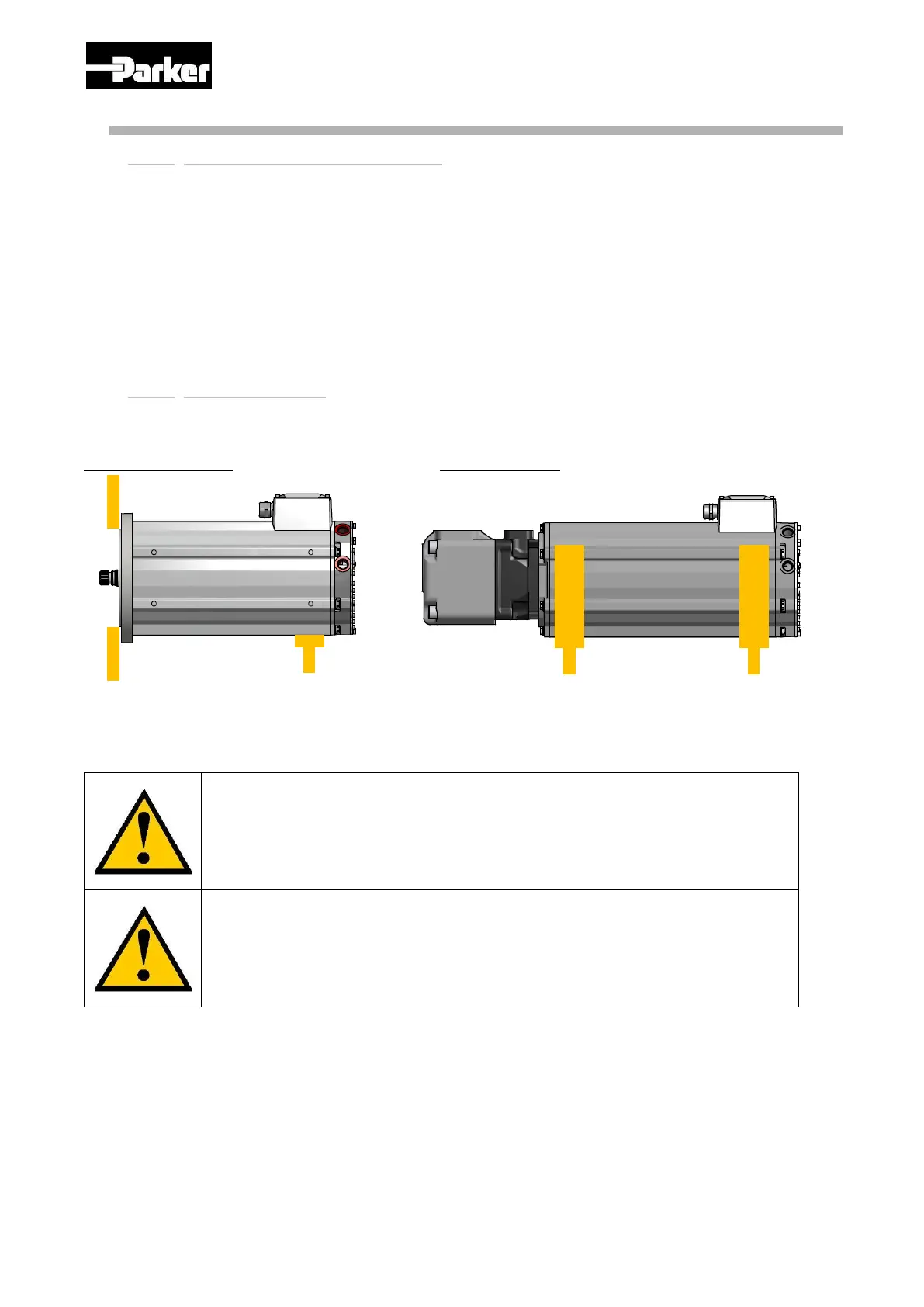

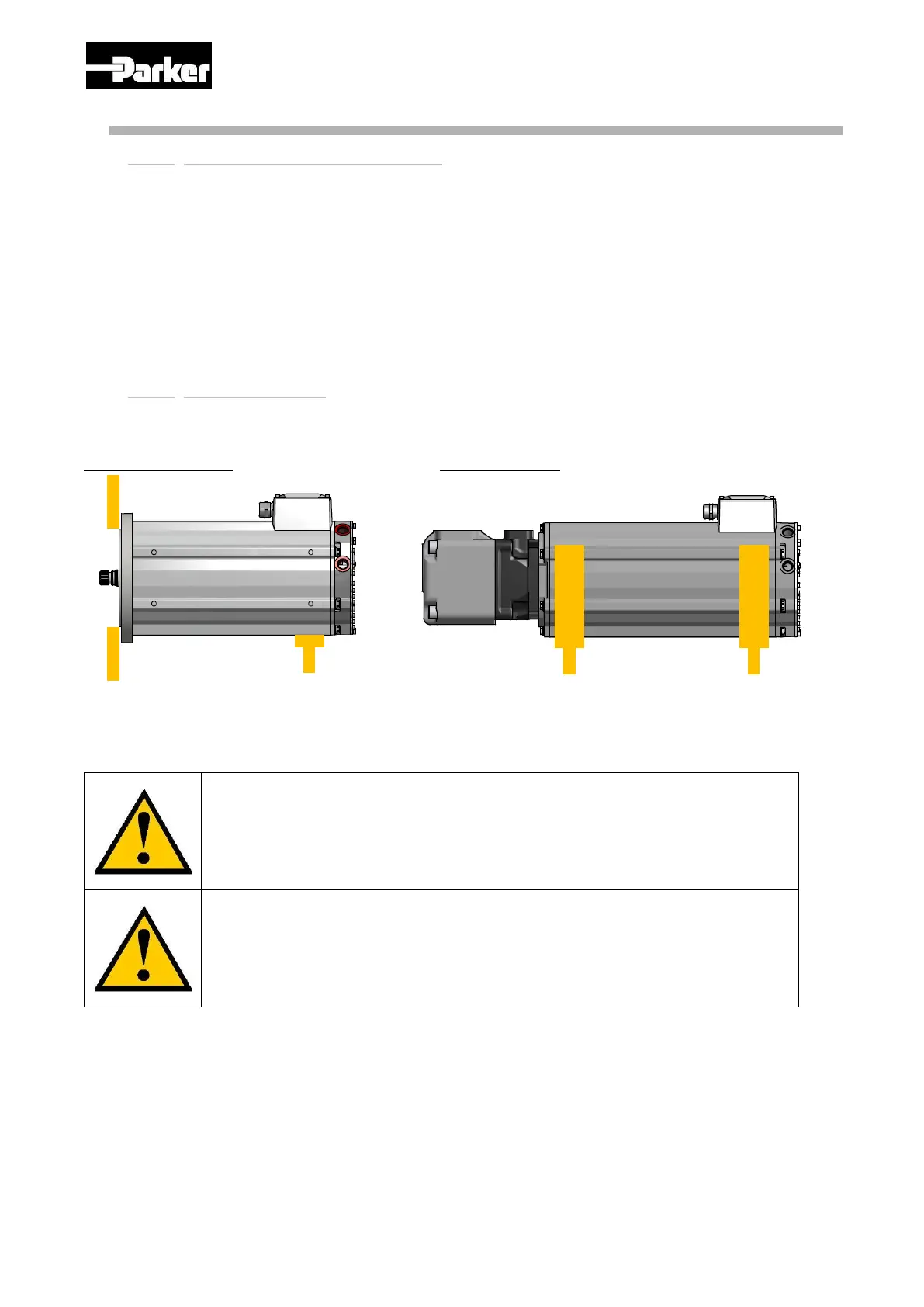

Traction mounting : EHP mounting :

GVM motors have been designed for an horizontal mounting (see §4.2). Considering the

above schematics, GVM motors have to be supported on their rear side.

For alternative mounting positions, please contact Parker.

GVM motors have been designed for being assembled on gearboxes or

hydraulic pumps and cannot support any axial / radial additional load on

the shaft.

Standard GVM motors dedicated to EHP applications have got a front

lip seal able to provide an IP67 protection level which means that it

cannot be put under pressure over 0.2 bar. For higher pressure (up to 5

bar) take the wet-spline coupling option for your GVM motor.

Loading...

Loading...