3

9926806 R03 - 2015 - 2016 RANGER ETX / 570 2-SEAT 2015 - 2016 RANGER 570 CREW Service Manual

© Copyright Polaris Industries Inc.

3.165

Installation

NOTE

To ease bearing installation, warm the crankcase

evenly with a heat gun or place in an oven and heat to

220-250° F. Place bearings in clean plastic wrap and

set in a freezer for 10-20 minutes.

5. Clean all bearings

e

and inspect for excessive wear.

NOTE

Apply Loctite® 641 to the inner race of each of the

crank bearings.

6. Lubricate all bearings

e

with clean engine oil.

7. Fully seat the new balance shaft bearing until

bottomed in the bearing bore.

8. Install the retaining ring

t

for the crankshaft

bearings.

9. Fully seat the new outer PTO crankshaft bearing

until bottomed against the retaining ring.

10. Install the bearing spacer

r

.

11. Press in the new inner PTO bearing until it is

bottomed against the bearing spacer.

12. Apply Loctite® 272™ to the two bearing retainer

bolts

q

.

13. Install the bearing retainer

w

and torque the fastener

to specification.

TORQUE

Bearing Retainer Fastener:

8 ft-lbs (11 Nm)Apply Loctite® 272™

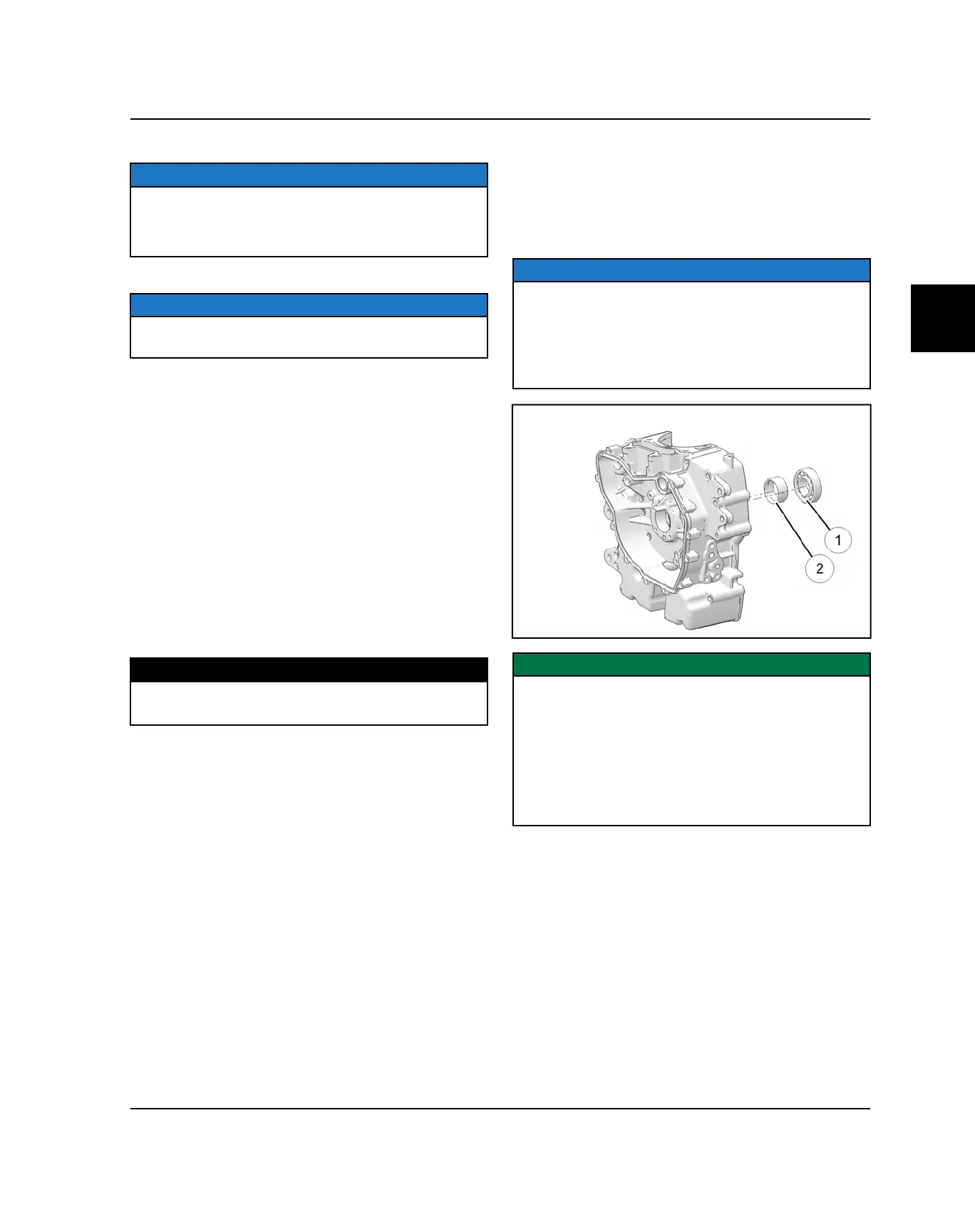

MAG SIDE CRANKCASE BEARING

SERVICE

Bearing Removal

1. Support the crankcase and drive, press, or extract

the balance shaft bearing

q

with a blind bearing

remover.

NOTE

The MAG side crankshaft plain bearing

w

is not

serviceable. Crankcase replacement is required if the

bearing is damaged or has excessive wear. The

crankshaft is reusable if it meets specifications and

MAG side bearing surface is not groved, pitted,

damaged or excessively worn.

IMPORTANT

Due to extremely close tolerances and minimal wear,

the bearings must be inspected. Look for discoloration,

scoring or galling. The inner race of each bearing

should turn smoothly and quietly. The outer race of

each bearing should fit tightly in the crankcase. The

inner race should be firm with minimal side to side

movement and no detectable up and down movement.

Bearings are stressed during the removal process and

must not be re-used!

Installation

2. Clean all bearing bores and inspect for excessive

wear.

3. Lubricate all bearing bores with clean engine oil.

4. Fully seat the new balance shaft bearing until

bottomed in the bearing bore.

ENGINE / COOLING SYSTEM

Loading...

Loading...