Page | 44

MAINTENANCE

______________________________________________________________________

Daily

Check the lift rope for any signs of wear. If in doubt, change the rope.

Check hydraulic hoses for any signs of wear. If in doubt change the hose.

Grease the mast where the driver weight runs.

Check all nuts and bolts are tight.

Weekly

Check the hydraulics for leaks

Check the rope pulleys turn freely

Check all pivots for wear

Grease all pivots

Machine operated in water and sea side :

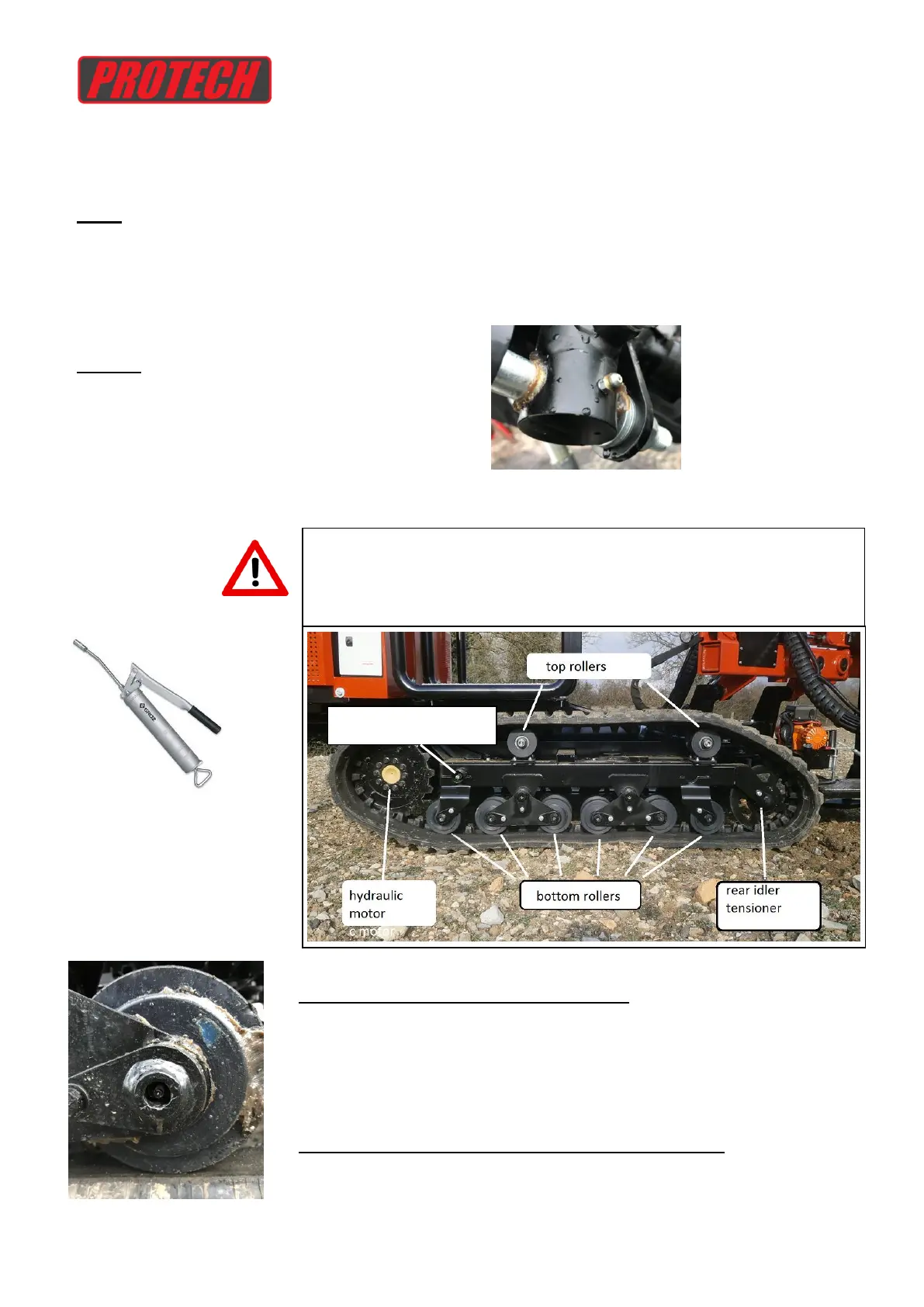

Grease generously with a grease pump using general purpose

grease. Bottom rollers (outside only) and Top rollers (inside and

outside) and rear idler wheel require weekly greasing when

machine is operated in severe conditions.

Machine operated in dry / mixed weather conditions :

Thorough monthly greasing is enough.

Use a manual or pneumatic

grease pump gun for track

tension and general greasing

Take special care to rollers which require bearings to be greased

with multipurpose grease stuffed with a grease pump to create

an internal pressure and avoid water and moisture ingression.

Loading...

Loading...