Section IV - QCS900 & QCS1600

QCS900/1600 Maintenance

Preparing for Maintenance

Shut off condensate inlet and switch

off compressor if necessary.

Inspect container, hoses and hose

connections for leaks regularly.

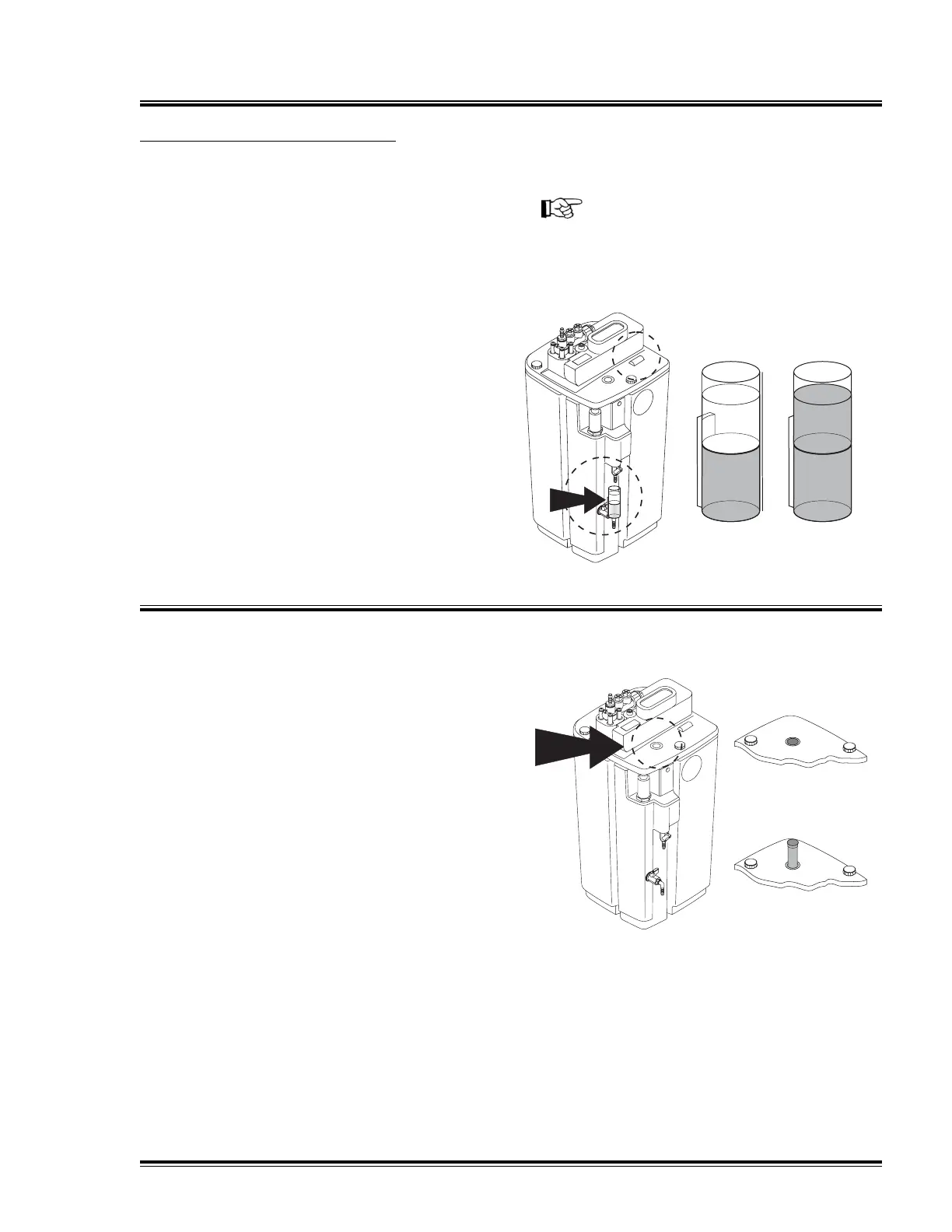

Weekly wastewater test:

Fill test tube at the sample valve.

Compare the test tube sample

cloudiness with the reference jar.

If the sample is clearer than the

reference jar the filter is okay (Figure

1).

If the sample is cloudier than the

reference jar the filter needs to be

changed (Figure 2).

♦

♦

♦

♦

♦

♦

notiCe

Never pour any foreign liquid into

the pressure relief chamber. This can

impair the filter efficiency.

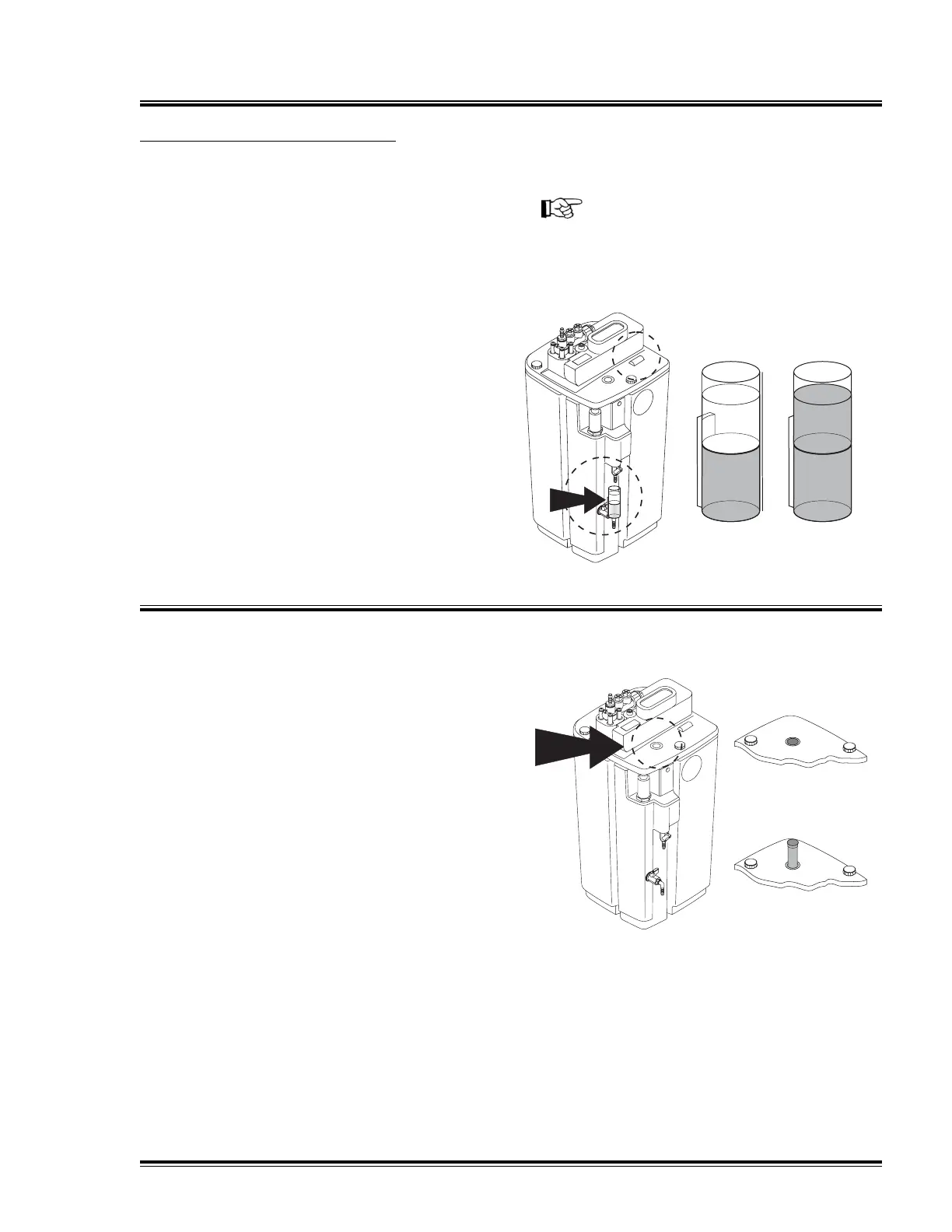

Level Indicator:

Level indicator not visible:

Filter condition of both stages is okay.

Red ring area visible:

Main filter stage is clogged. Replace

filter set.

The level indicator can be equipped with

an alarm contact as an option. This contact

switches in the event of a rising fill level

inside the QCS unit due to:

Excessive inflow quantity.

Clogged filter.

Water outlet not functioning correctly.

♦

♦

♦

♦

♦

Quincy Compressor-QCS High Efficiency Emulsion Separators 23

Loading...

Loading...