TABLE 1

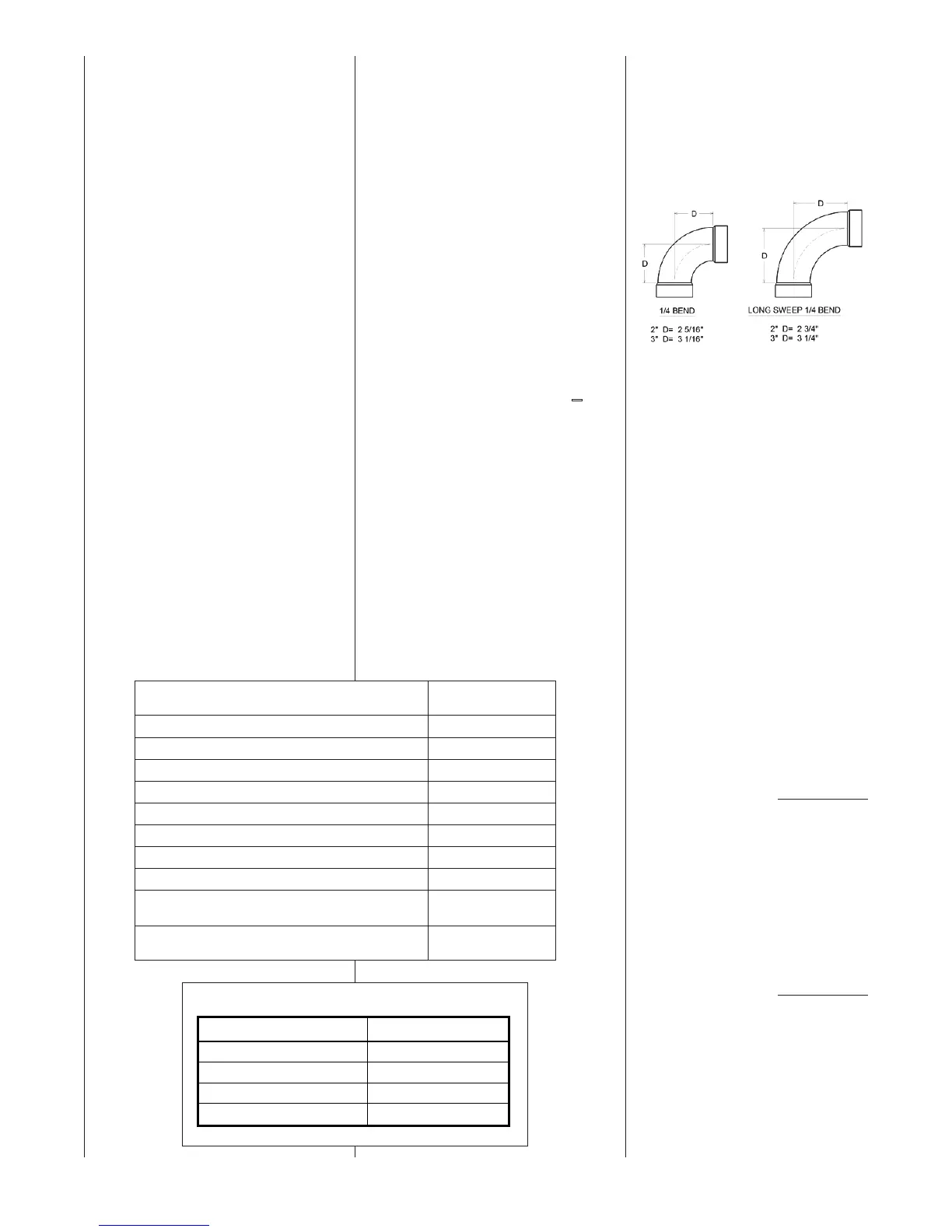

There are several different types of

elbows that can be used for con-

structing a vent system. The draw-

ings below show the dimensions of

common 1/4 bend and 1/4 bend long

sweep 90 degree elbows from ASTM

3311, Standard Specification for

Drain, Waste and Vent (DWV) Plastic

Fittings Patterns.

A long sweep 1/4 bend 90 degree

(long radius) elbow has an equivalent

length of 5 feet of straight pipe for

eit

her 2 or 3 inch plastic pipe. A stan-

dard 90° elbow has an equivalent

length of 10 feet of pipe. This equiva-

lent length can be used in circum-

stances where it might be necessary

to lengthen the vent at the outside of

the structure, such as in areas with

large accumulations of snow in win-

ter. Table 1 shows the equivalent

lengths of different types of elbows:

With the equivalent length vent

concept a ven

t system can be

used any number of elbows and

length of straight pipe as long as

the maximum equivalent vent

length is not exceeded.

Example:

An RGRC-06 direct vent installation

needs a 31 foot long vent run with 5

elbows and 2 inch pipe.

31 feet of 2 inch pipe = 31

equivalent feet

5 - 1/4 bend long sweep

elbows = 25

equivalent feet

Total = 56

equivalent feet

Since the maximum equivalent vent

length for an RGRC-06 is 60 feet, this

installation is acceptable.

If the same installation tried to use

standard elbows:

31 feet of 2 inch pipe = 31

equivalent feet

5 - standard 90 degree

= 50

equivalent feet

Total = 81

equivalent feet

And this installation is not acceptable

as it exceeds the 60 foot maximum

listed for the RGRC-06 model.

CEMENTING JOINTS

Properly seal all joints in the PVC vent

using the following materials and pro-

cedures:

PVC CLEANER-PRIMER AND

PVC MEDIUM-BODY SOLVENT

CEMENT

IMPORTANT: After cutting pipe,

remove all ragged edges and burrs.

This is important to prevent increase

in pressure

drop throughout the sys-

tem.

1. Cut pipe end square. Chamfer

edge of pipe. Clean fitting socket

and pipe joint area of all dirt,

grease and moisture.

2. After checking pipe and socket

for proper fit, wipe socket and

pipe with cleaner-primer. Apply

a liberal coat of primer to inside

surface of socket and outside of

pipe. READ INSTRUCTIONS

INCLUDED WITH THE PRIMER

FOR PROPER INSTALLATION.

3. Apply a thin coat of c

ement even-

ly in the socket. Quickly apply a

heavy coat of cement to the pipe

end and insert pipe into fitting

with a slight twisting movement

until it bottoms out.

NOTE: Cement must be fluid; if

not, recoat.

4. Hold the pipe in the fitting for 30

seconds to prevent the tapered

socket from pushing the pipe out

of the fitting.

5. Wipe all excess cement from the

joint with a rag. Allow 15 minutes

before handling.

Cure time varies

according to fit, temperature and

humidity.

NOTE: Stir the solvent cement fre-

quently while using. Use a natural

bristle, one inch wide brush or the

applicator supplied with the can.

IMPORTANT: For Proper Installation DO

NOT use solvent cement that has

become curdled, lumpy or thickened.

DO NOT thin. Observe shelf precautions

printed on containers. For application

below 32°F, use only low-t

emperature-

type solvent cement.

For correct installation of the vent pipe,

follow the instructions provided by the

manufacturers of the pipe, primer and

solvent.

EQUIVALENT VENTING

–

ASSIGNING VENT

LENGTH TO ELBOWS

This section applies to venting tables in

both the NON-DIRECT and DIRECT

VENT tables in this book. Vent tables

are provided only in equivalent length

and do not reference elbows or a maxi-

mum number of elbows. Instead, elbows

are assigned a length as described

below. The length determined for each

elbow is subtracted from the max vent

length in the tables to determine how

much

straight vent pipe (in ft) can still be

used.

PIPE & FITTING MATERIAL

ASTM

SPECIFICATION

Schedule 40 PVC (Pipe) D1785

Schedule 40 PVC (Cellular Core Pipe) F891

Schedule 40 PVC (Fittings) D2466

SDR-21PVC (Pipe) D2241

SDR-26 PVC (Pipe) D2241

Schedule 40 ABS Cellular Core DWV (Pipe) F628

Schedule 40 ABS (Pipe) D1527

Schedule 40 ABS (Fittings) D2468

ABS-DWV (Drain Waste & Vent)

(Pipe & Fittings)

D2661

PVC-DWV (Drain Waste & Vent)

(Pipe & Fittings)

D2665

13

EQUI VAL ENT VENTI NG – ASSI GNI NG VENT L ENTGH TO

EL BOWS

T hi s sect i on appl i es to venti ng tables i n both the NON-DI REC T and DI RECT VENT tabl es i n t hi s

book. Vent t abl es ar e pr ovi ded only in equi val ent l ength and do not reference elbows or a maximum

num ber of el bows. I nst ead, el bow s are assi gned a lengt h as descri bed bel ow. The l engt h det ermi ned

f or each el bow i s subtracted from t he max vent length in the tables to determine how much strai ght

v ent pi pe ( i n f t ) can st i l l be used.

T her e ar e sever al di f f er ent t ypes of elbows that can be used for constructi ng a v ent syst em . T he

drawi ngs bel ow show the dimensi ons of common ¼ bend and ¼ bend l ong sweep 90 degree el bow s

f rom ASTM 3311, Standard Speci f i cati on f or Drain, Waste and Vent (DWV) Plastic Fittings

Pat t er ns.

A l ong sweep ¼ bend 90 degree (l ong radi us) el bow has an equivalent l ength of 5 f eet of strai ght

pi pe f or ei ther 2 or 3 i nch pl ast i c pi pe. A st andar d 90° el bow has an equi val ent l ength of 10 f eet of

pi pe. Thi s equi valent l ength can be used i n ci rcumst ances w her e i t mi ght be necessary to lengthen the

v ent at t he out si de of t he structure, such as i n ar eas wi th l arge accumul ati ons of snow i n wi nter.

Table 1 show s the equi val ent l engths of different types of el bows:

T abl e 1

Fitting Type Equivalent L engt h

45° Standard Elbow 5 f eet of pipe

90° Standard Elb ow 1 0 f eet of pip e

45° Long- Sweep Elbow 2-1/2 f eet of pipe

90° Long- Sw eep Elbow 5 f eet of pipe