43

LP GAS AT HIGH ALTITUDE

ELEVATIONS IN THE U.S.

LP Gas is a manufactured gas that has

consistent heating value across most

regions.

The National Fuel Gas Code (N.F.G.C.)

guidelines are used with the following

exception:

The recommended LP Gas high altitude

orifice selections differ slightly in that

the NFGC LP orifice chart, as they are

not accurate for the RGFG gas fur-

naces. The National Fuel Gas Code LP

or

ifices a

re based on an 11” of water

column pressure at the orifice, which

differs from products that use 10” of

water column at the orifice. This differ-

ence requires a deviation from the

NFGC orifice size recommendations.

The Sea Level input should still be

reduced by 4% per thousand ft. and the

orifice size must be selected based on

the reduced input selection shown in

Table 13.

Orifice Ordering Informati

on

O

rifice sizes are selected by adding the

2-digit drill size required in the orifice

part number. Drill sizes available are 39

through 64; metric sizes available

1.10mm (-90) and 1.15mm (-91):

Orifice Part Number 62-22175-(drill

size)

Example 1:

#60 drill size orifice required

Part #62-22175-60

Example 2:

1.15mm drill size orifice required

Part #62-22175-91

ALTERNATE METHOD FOR

CANADIAN

HIGH-ALTITUDE

DERATE

In Canada, unless an orifice change is

specifically mandated by local codes,

an alternate method of altitude deration

through a reduction in manifold pres-

sure is acceptable as described in

Table 14.

The information in Table 14 is based on

a heating value of 1000 BTU per cubic

feet of natural gas, and 2500 BTU per

cubic feet of LP gas.

IMPORTANT: Actual input rates must

be measured on-site with manifold

pressure adjustment to ensure that an

actual 10% reduction in input rate is

achieved.

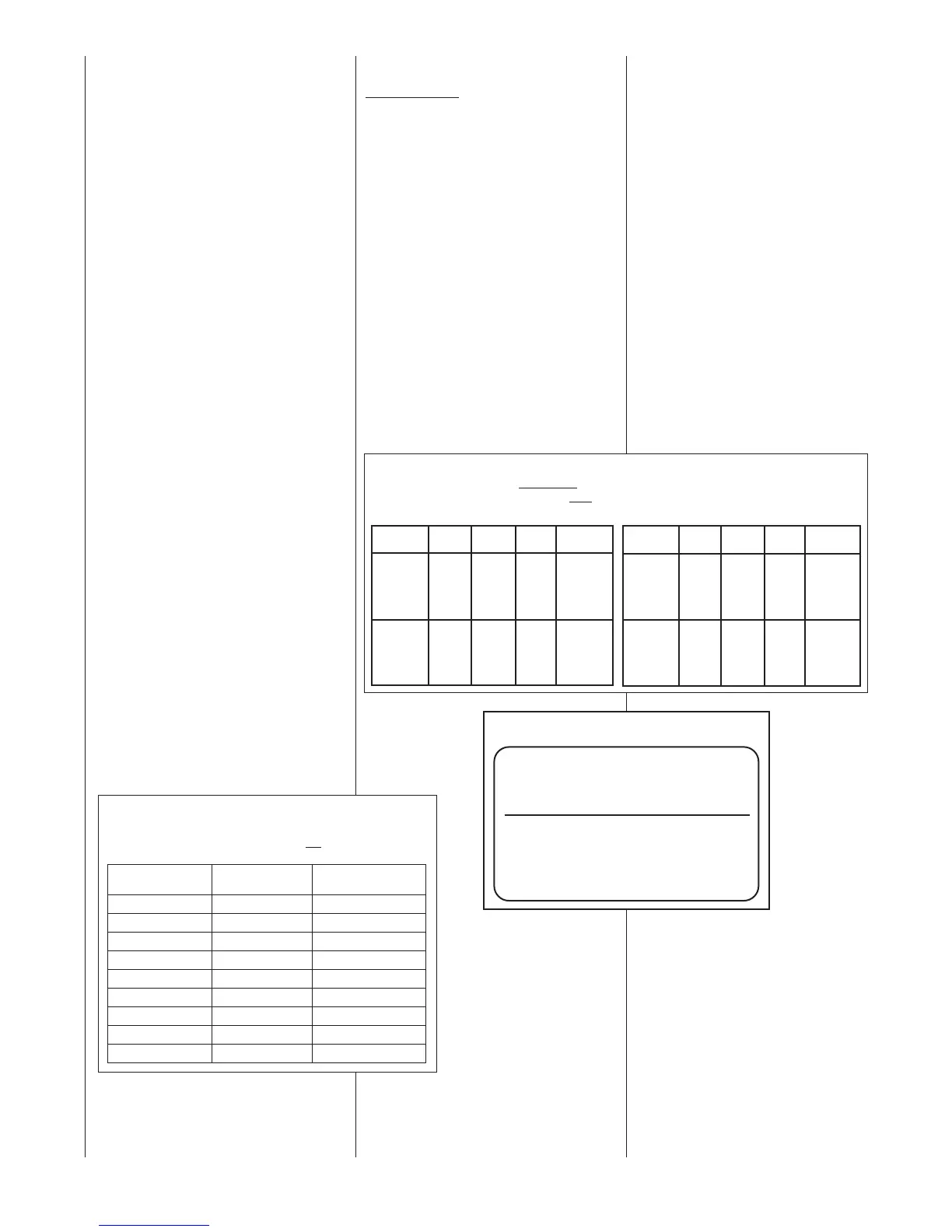

TABLE 13

LP Gas Orifice Drill Size and per burner de-rate by elevation based

on 15,000 btu 90+ burners.

IMPORTANT: For 90+ Furnaces only. Do not use this chart for any

80+ Furnace.

Input (per Orifice

Altitude burner) 15000 Size

0 to 2000 ft. 15000 1.15 mm (factory)

2001ⴕ to 3000ⴕ 13200 1.15 mm

3001ⴕ to 4000ⴕ 12600 1.10 mm

4001ⴕ to 5000ⴕ 12000 #58

5001ⴕ to 6000ⴕ 11400 #59

6001ⴕ to 7000ⴕ 1080 #60

7001ⴕ to 8000ⴕ 10200 #62

8001ⴕ to 9000ⴕ 9600 #63

9001ⴕ to 10000ⴕ 9000 #64

TABLE 14

ALTERNATE METHOD FOR CANADIAN HIGH-ALTITUDE DERATE

IMPORTANT: 90+ MODELS ONLY. DO NOT

USE THIS CHART FOR ANY 80 PLUS MODELS.

NATURAL GAS LP GAS

ALTITUDE

INPUT

OUTPUT

ORIFICE

SIZE

MANIFOLD

PRESSURE

0’ - 2000’

45,000

60,000

75,000

90,000

105,000

120,000

40,500

54,000

67,500

81,000

94,500

108,000

#50

3.5” W.C.

2001’ - 4500’

40,500

54,000

67,500

81,000

94,500

108,000

36,450

48,600

60,750

72,900

85,050

97,200

#51

3.0” W.C.

ALTITUDE

INPUT

OUTPUT

ORIFICE

SIZE

MANIFOLD

PRESSURE

0’ - 2000’

45,000

60,000

75,000

90,000

105,000

120,000

40,500

54,000

67,500

81,000

94,500

108,000

1.15mm

10” W.C.

2001’ - 4500’

40,500

54,000

67,500

81,000

94,500

108,000

36,450

48,600

60,750

72,900

85,050

97,200

1.10mm

7.6” W.C.

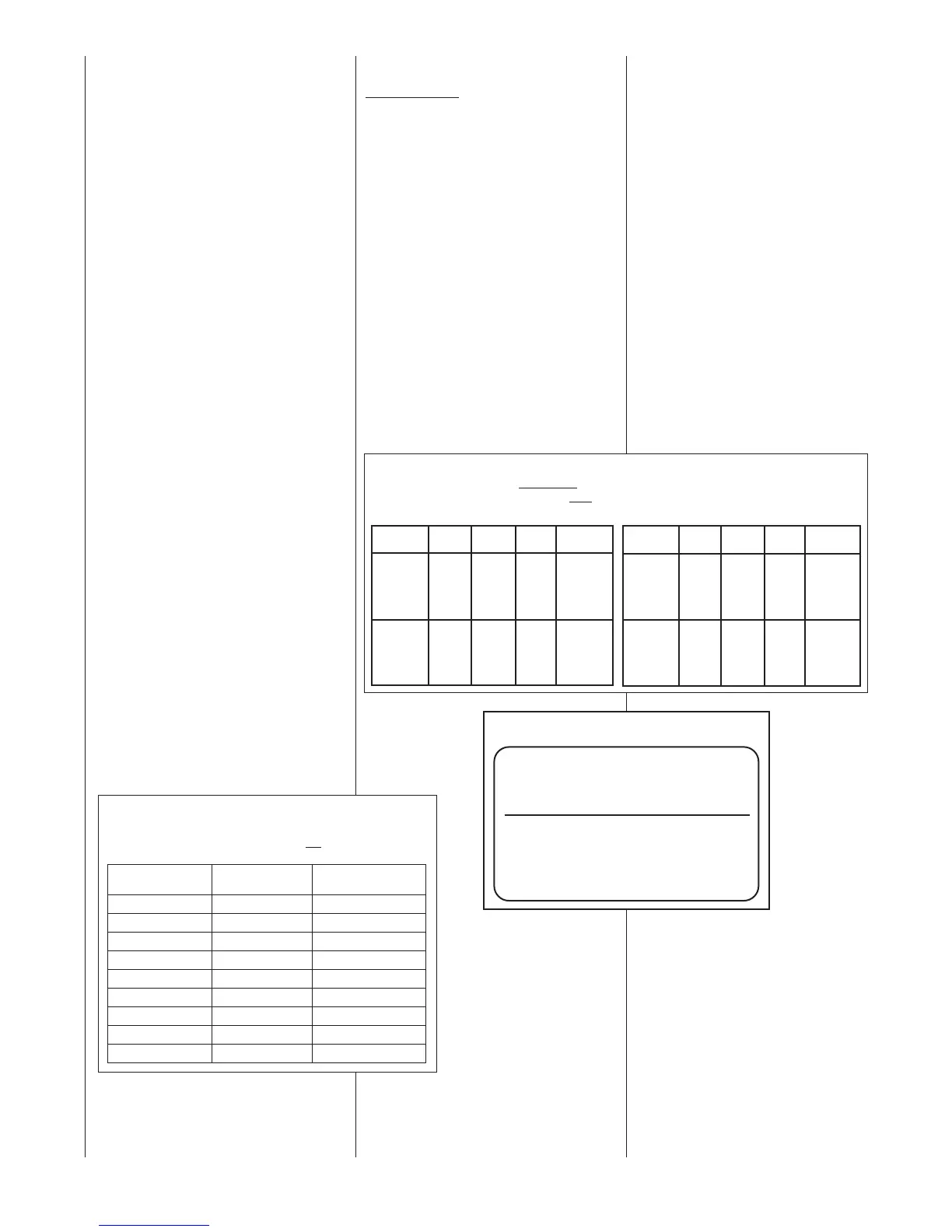

FIGURE 35

MANIFOLD PRESSURE-CHANGE LABEL

THE MANIFOLD PRESSURE OF THIS APPLIANCE HAS

BEEN FIELD ADJUSTED TO OBTAIN THE CORRECT

INPUT RATING FOR INSTALLATION AT ALTITUDES

BETWEEN 2,000 FEET AND 4,500 FEET ELEVATION.

LA PRESSION DU DISTRIBUTEUR D’ALIMENTATION

DE CET APPAREIL A ÉTÉ AJUSTÉ SUR LES LIEUX AFIN

D’OBTENIR LA BONNE PUISSANCE D’ENTRÉE POUR

UNE INSTALLATION ENTRE 2000 ET 4500 PIEDS

D’ALTITUDE.

92-24399-01-01

Once this field adjustment has been

made, the label shown in Figure 35

must be affixed in a conspicuous

location on the front of the furnace

cabinet:

NOTE: This label is supplied in the

information packet shipped with each

furnace.

Loading...

Loading...