When Print Quality Is Not Satisfactory

18

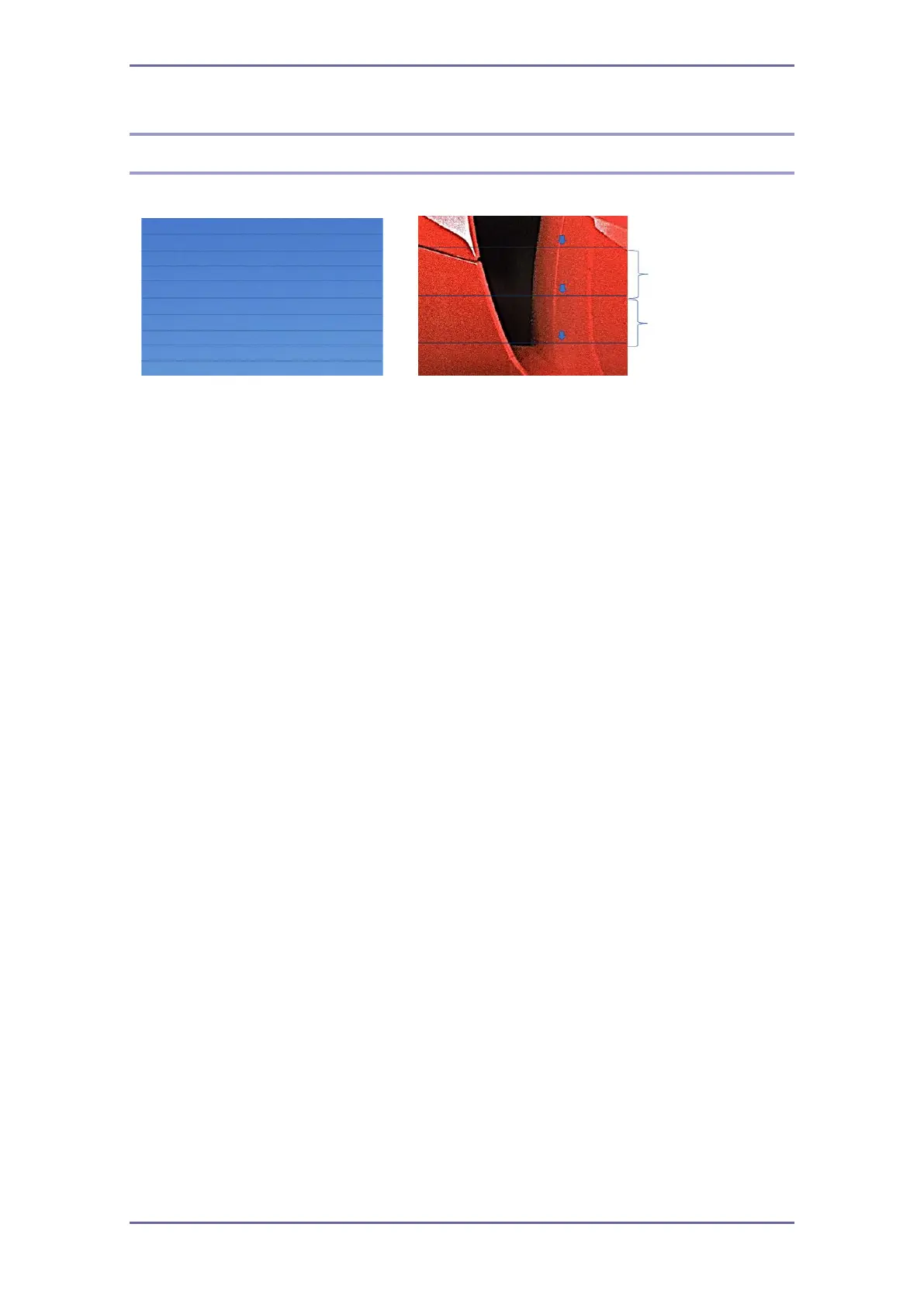

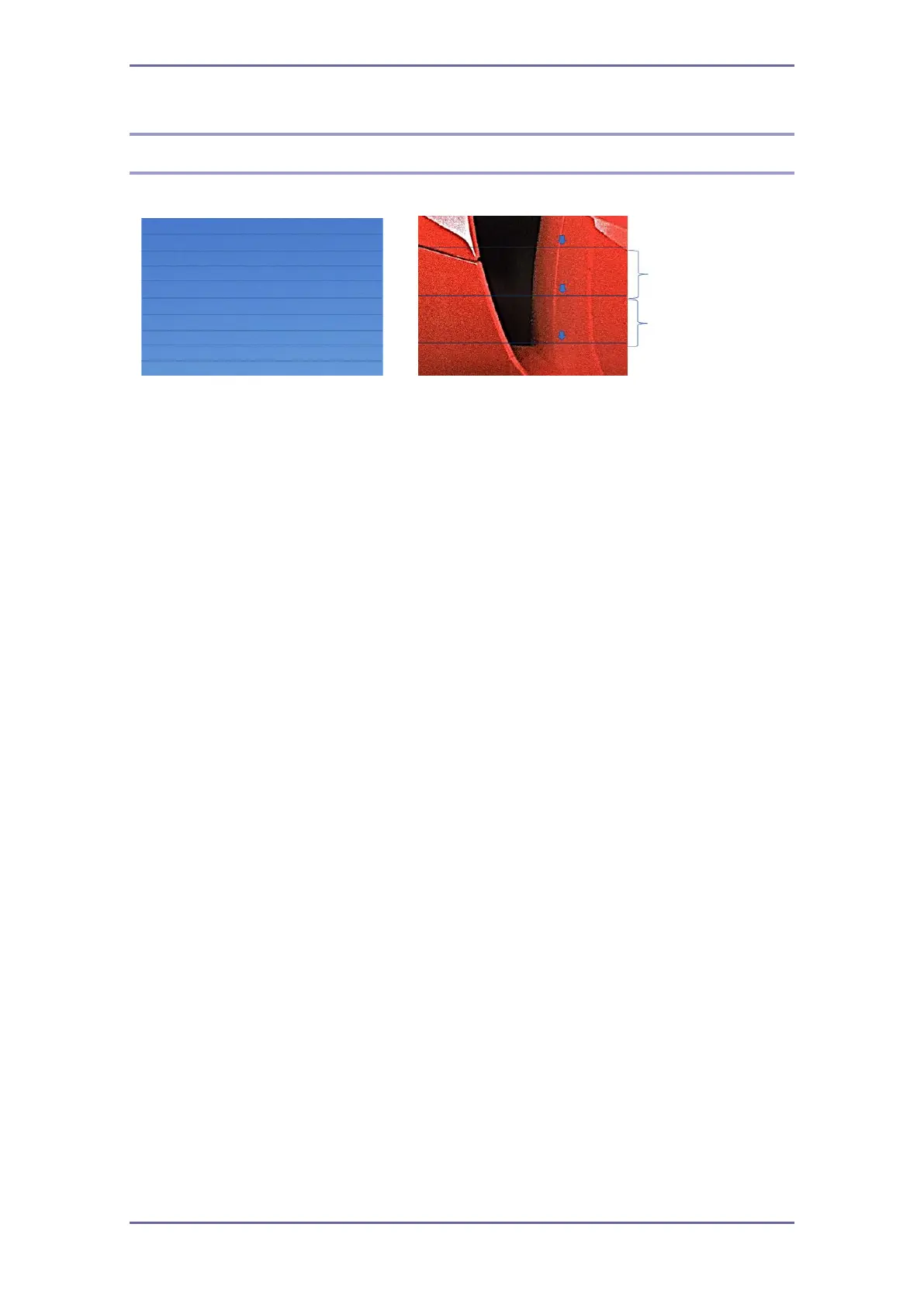

Black Lines (Major case)

[Cause/Technical reason]

1. The media feed quantity is not correct.

Not adjusted properly or Media Feed Adjustment (micro setting) are too short.

2. Heater temperature is not enough to dry the dropped ink.

In the case of using high speed mode (6pass or 8pass), black lines occur at only dark

image position due to too much ink.

[Solution]

1. Adjust the feed quantity correctly, because optimal feed quantity differs from each media.

See the section "Adjusting the Media Feed Quantity” in the manual” Operating Instructions”.

Adjusted the media feed with the part where the media has been fed and moved back or the

deforming media due to heating.

The rewound media and heated media are damaged by the registration roller and heater

temperature. If you adjust feed quantity in damaged part, Black lines may occur on

undamaged part, because the optimal feed quantity may differ between damaged part and

undamaged part.

2. Change the Heater temperature settings to higher or raise the drying time.

Change the pre and print heater settings higher by about +10 ℃.

Use UNI direction to raise the drying time. It can be select on RIP software.

When using ONYX rip, open print setting → select UNI direction on printing direction.

When using ColorGATE RIP, right click on the job → select “Settings” → select “Advanced

Settings” under the “Color” tab → Select the “Print Mode” tab and untick “Bidirectional”

Loading...

Loading...