58 Rockwell Automation Publication 440R-UM013F-EN-P - July 2021

Chapter 11 Troubleshooting

can install a separate SELV supply for your safety system and leave it

ungrounded (no protective ground).

Check Safety Device Inputs

(Step 3)

This step only applies to CI, DI, DIS, and SI safety relays. Each safety relay has

a status indicator for its inputs.

Table 14

shows the voltage levels that are viewed on an oscilloscope versus a

digital multimeter.

Check Voltage-free Contacts

Safety devices (for example; interlock switches, E-stops, or cable pull switches)

with voltage-free contacts must be connected to the pulse testing outputs. You

can use a digital multimeter to measure the input levels.

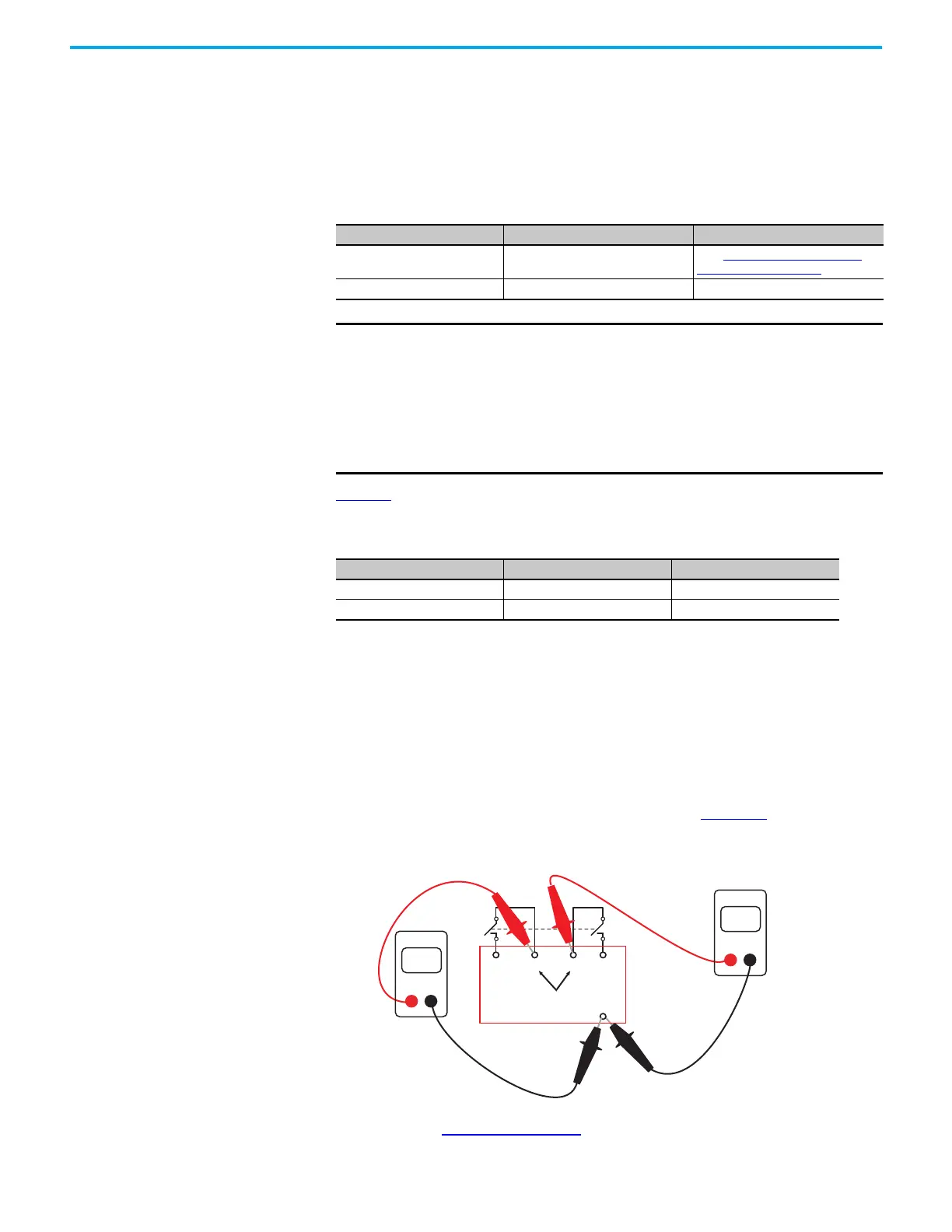

Check CI Safety Relay

1. With the device contacts open, measure the voltage at the pulse testing

outputs with a digital multimeter, as shown in Figure 60. The voltage

must be 18…19V on both pulse testing outputs of the CI safety relay.

Figure 60 - Typical Voltage Measurements of the CI Safety Relay

2. Check the voltage at each of the inputs with the device contacts closed, as

shown in Figure 61 on page 59. The values must be very close to the values

measured at terminals S11 and S21.

Table 13 - Input Indicator

IN, IN1, and IN2 Indicator Status Action

Green Both channels are closed

Go to Check the Single Wire Safety

Circuit (Step 4) on page 64.

Off One or both input channels are open Continue with this section.

IMPORTANT The following factors affect the value that is measured at the relay

inputs:

• Voltage-free contacts

•Pulse testing waveforms

• Capacitance

• Length of wire

• Contact resistance

• Channel sequence

Table 14 - ON/OFF Voltage

Measurement Device Turn ON Voltage Turn OFF Voltage

Oscilloscope 11V 5V

Digital Multimeter 6…8V 3…4V

S11 S21S12

19

19

S22

A2

Volts

DMM

Volts

DMM

Loading...

Loading...