4 x Commissioning

36

FA ROTEX Solaris - 08/2007

11. The thermal insulation can now be applied to the pipe joints (e.g. between Connect SCS and Connect VG).

12. Instruct the user, fill out the acceptance report and send it to the address indicated on the rear cover of this manual.

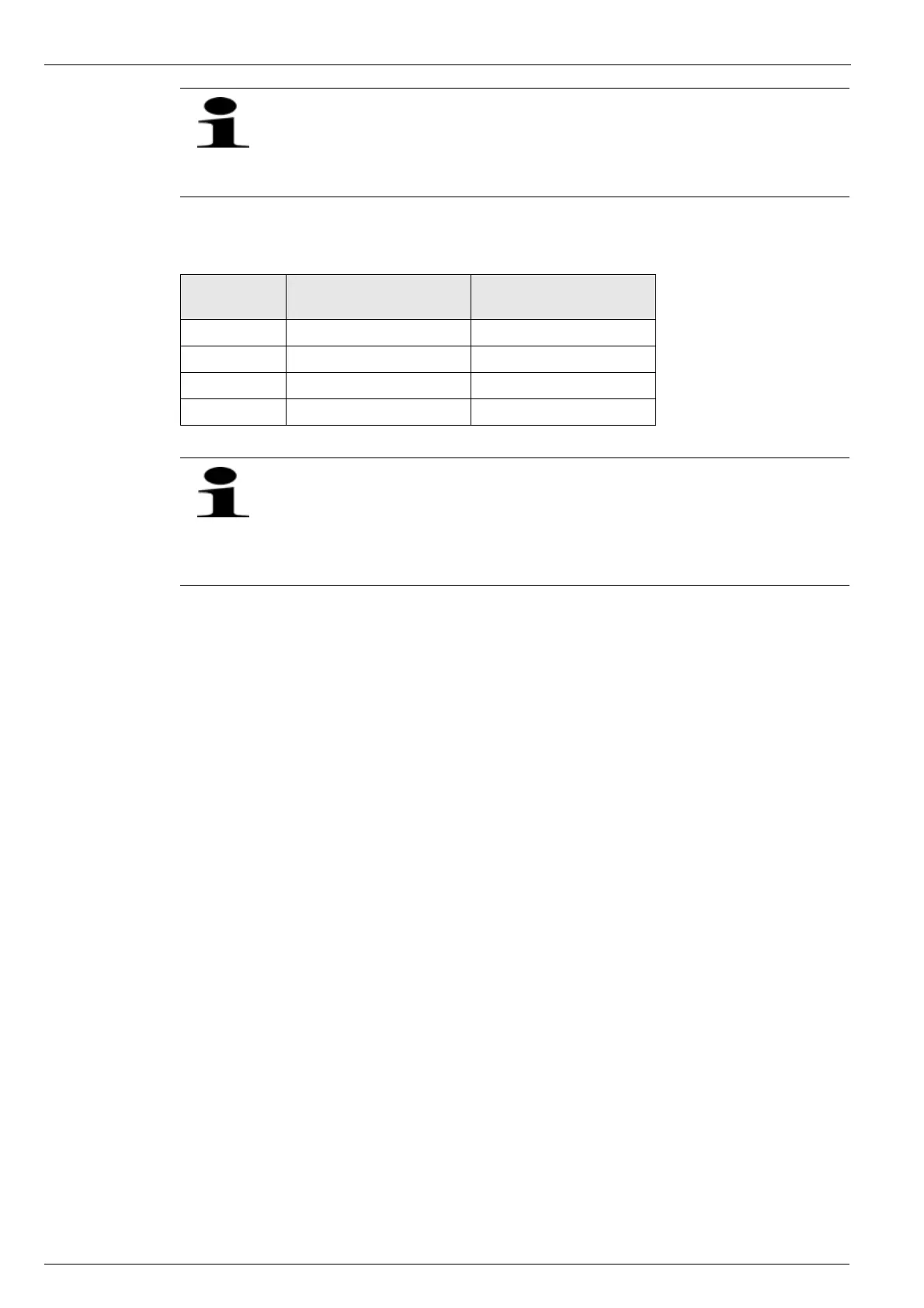

Tab. 4-3 Reference values for setting the flow on systems without a FlowSensor

4.2 Operation of Solaris systems with a FlowSensor

1. Filling the storage container:

• Fill the heat exchanger for domestic water.

• Fill the storage container via the filling & draining cock on the RPS3 until water comes out of the safety overflow.

• Close the filling & draining cock.

2. Switch on the Solaris R3 control unit (initialising phase starts).

3. When the initialising phase is complete (temperature display), you can vent the system by simultaneously pressing both

arrow keys (starts the manual operating mode).

Both pumps are now running at full capacity and the system is subjected to the max. possible operating pressure. The system is

filled with water and the air escapes through the inflow pipe into the air space of the storage container.

4. Check the entire system for leaking joints (in the building and on the roof). Any leaks must be repaired by a qualified

technician.

5. Switch off the Solaris control unit.

6. Check the level in the Solaris Sanicube.

The pumps are only switched on if the solar panel temperature is higher than the minimum value for frost

protection (see Section 5.2.10) and lower than the adjusted max. permissible temperature.

If there has been a longer pause between working steps 5 and 7, the solar panel temperature might be outside

the permissible range. However, this can be overcome by switching over to manual operation for a few minutes

(see Section 5.2.5).

Number of solar

panels

Desired flow in l/min Desired flow in l/h

2 3.0 to 4.0 180 to 240

3 4.5 to 6.0 270 to 360

4 6.0 to 8.0 360 to 480

5 7.5 to 10.0 450 to 600

The final valve setting can only be determined on a sunny day during normal operation (only one pump)

according to the temperature differences that are reached. With good solar radiation, the solar panel

temperature should settle at a value that is about 10 to 15°C above the return flow temperature.

If a calorimeter has been installed in the system, the flow can be adjusted according to the calorimeter display.

During normal operation (circulation pump on/booster pump off) the value per solar panel should be about 90 to

120 l/h (1.5 to 2.0 l/min).

Loading...

Loading...