-

Names

and

Functions

For the explanation about the symbols for the operation switches, please read this chapter carefully. They are designed

following the DIN 30600 (symbols).

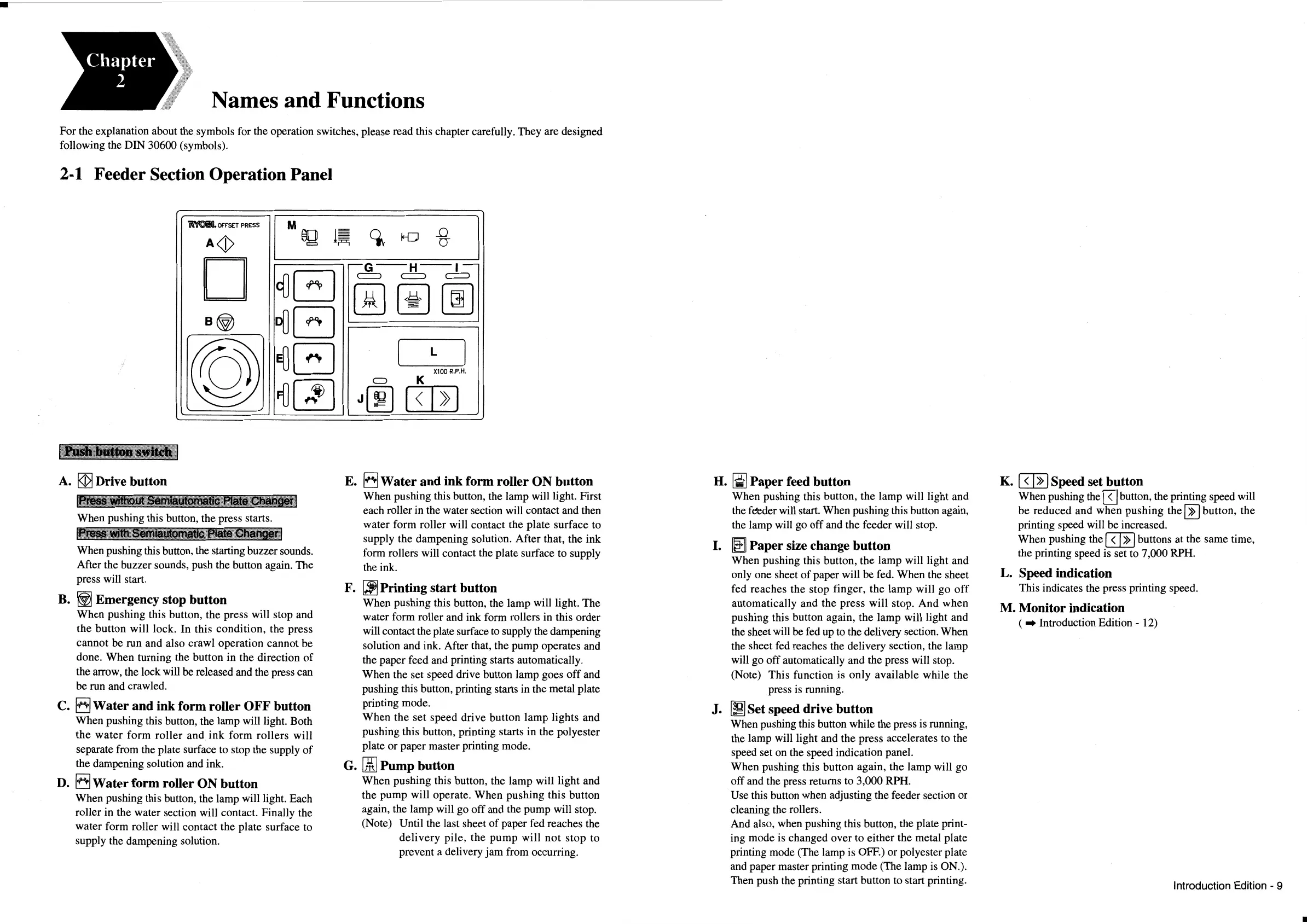

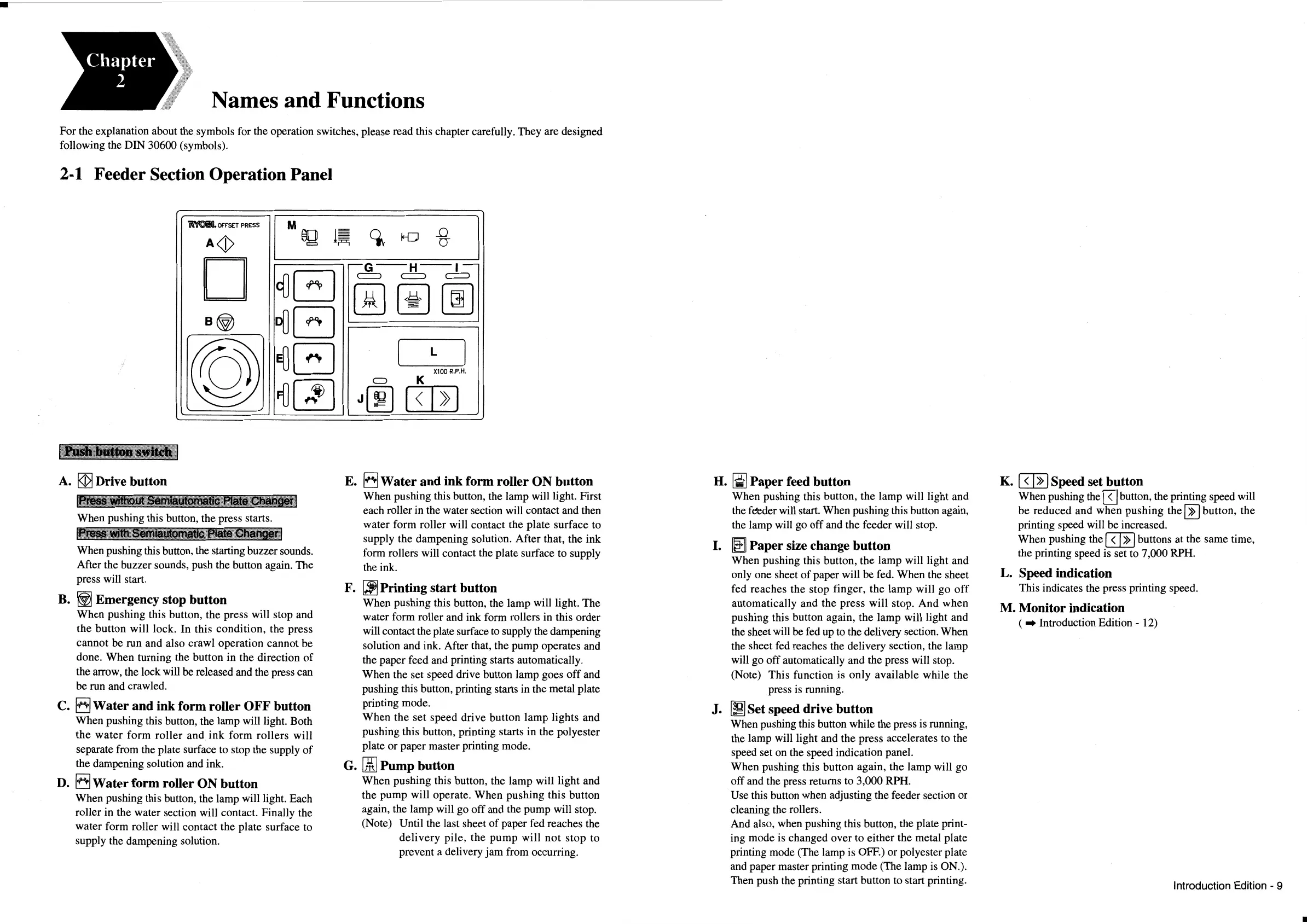

2-1 Feeder Section Operation Panel

~OFFSET

PRESS

I

M@g

.D

I

A<i)

1;=;

Civ

io-0

0"

D

-G

H

1-

9JE]

~

00

00

e@

~EJ

,(@)

~El

~[;!]

A.

~

Drive button

=ill

When pushing this button, the starting buzzer sounds.

After the buzzer sounds, push the button again. The

press will start.

B.

~

Emergency stop button

When pushing this button, the press will stop and

the button will lock. In this condition, the press

cannot be run and also crawl operation cannot be

done. When turning the button in the direction

of

the arrow, the lock will

be

released and the press can

be run and crawled.

C.

~Water

and

ink form roller

OFF

button

When pushing this button, the lamp will light. Both

the

water

form

roller

and

ink

form rollers will

separate from the plate surface to stop the supply

of

the dampening solution and ink.

D.

~Water

form roller ON button

When pushing this button, the lamp will light. Each

roller in the water section will contact. Finally the

water form roller will contact the plate surface to

supply the dampening solution.

[

L

l

X100

R.P.H.

C)

K

Joo

[ill]

E.

~Water

and

ink form roller ON button

When pushing this button, the lamp will light. First

each roller in the water section will contact and then

water form roller will contact the plate surface to

supply the dampening solution. After that, the ink

form rollers will contact the plate surface to supply

the ink.

F.

lil]

Printing

start

button

When pushing this button, the lamp will light. The

water form roller and ink form rollers in this order

will contact the plate surface to supply the dampening

solution and ink. After that, the pump operates and

the paper feed and printing starts automatically.

When the set speed drive button lamp goes

off

and

pushing this button, printing starts in the metal plate

printing mode.

When the set speed drive button lamp lights and

pushing this button, printing starts in the polyester

plate or paper master printing mode.

G. [i]

Pump

button

When pushing this button, the lamp will light and

the pump will operate. When pushing this button

again, the lamp will go off and the pump will stop.

(Note) Until the last sheet

of

paper fed reaches the

delivery pile, the

pump

will

not

stop

to

prevent a delivery jam from occurring.

H.

[$i]

Paper

feed button

When pushing this button, the lamp will light and

the freder will start. When pushing this button again,

the lamp will go

off

and the feeder will stop.

I.

[§j]

Paper

size change button

When pushing this button, the lamp will light and

only one sheet

of

paper will be fed. When the sheet

fed reaches the stop finger, the lamp will go

off

automatically and the press will stop. And when

pushing this button again, the lamp will light and

the sheet will

be

fed up to the delivery section. When

the sheet fed reaches the delivery section, the lamp

will go

off

automatically and the press will stop.

(Note) This function is only available while the

press

is

running.

J.

~Set

speed drive button

When pushing this button while the press

is

running,

the lamp will light and the press accelerates to the

speed set on the speed indication panel.

When pushing this button again, the lamp will go

off and the press returns to 3,000 RPH.

Use this button when adjusting the feeder section or

cleaning the rollers.

And also, when pushing this button, the plate print-

ing mode is changed over to either the metal plate

printing mode (The lamp

is

OFF.) or polyester plate

and paper master printing mode (The lamp

is

ON.).

Then push the printing start button to start printing.

K. 8:li] Speed set button

When pushing the

8J

button, the printing speed will

be reduced and when pushing

the~

button, the

printing speed will be increased.

When pushing the

8:liJ

buttons at the same time,

the printing speed

is

set to 7,000 RPH.

L.

Speed indication

This indicates the press printing speed.

M. Monitor indication

( • Introduction Edition- 12)

Introduction Edition - 9

Loading...

Loading...