PLC Subroutines Manual

6FC5397-0FP40-0BA0, 08/2013

69

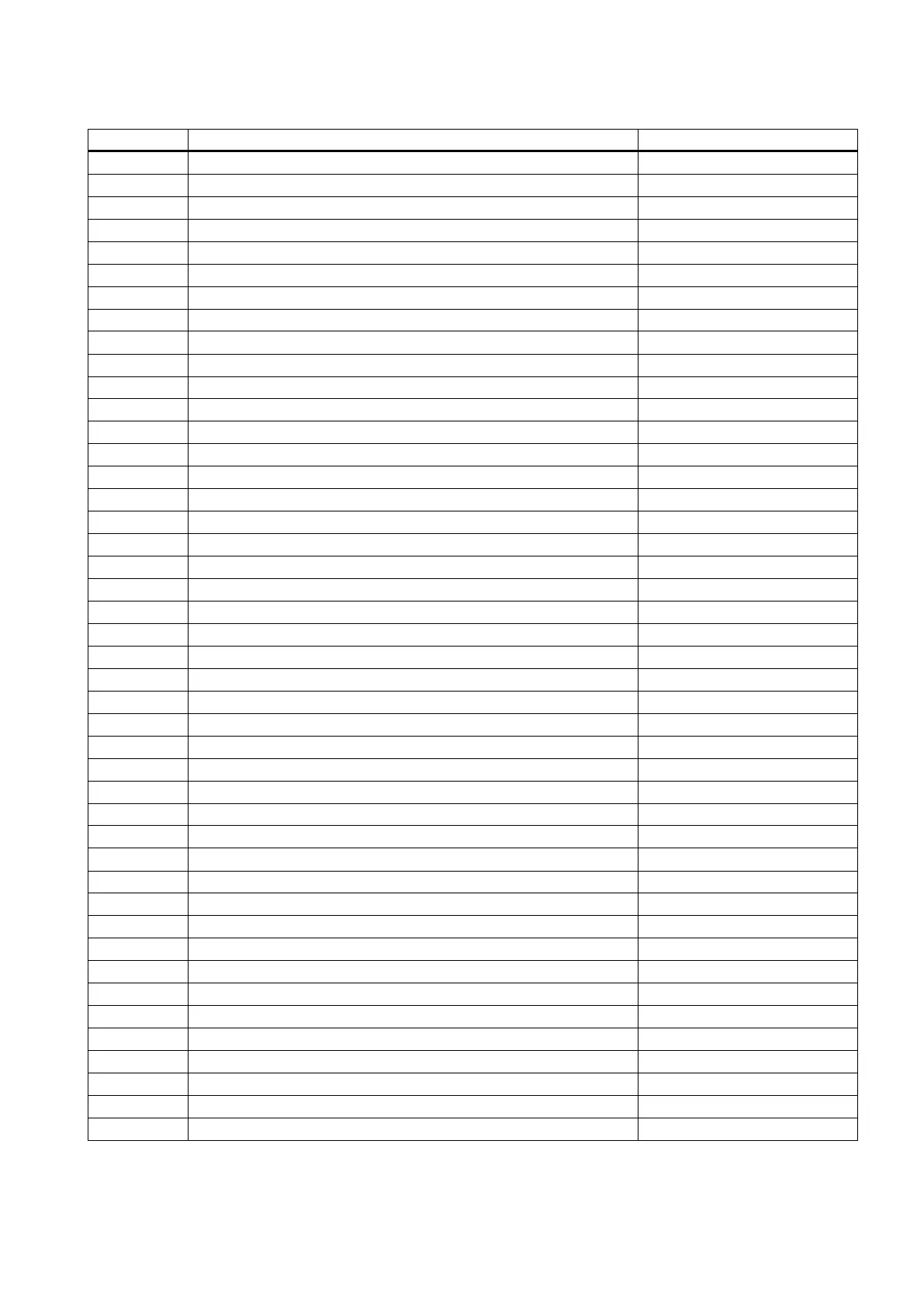

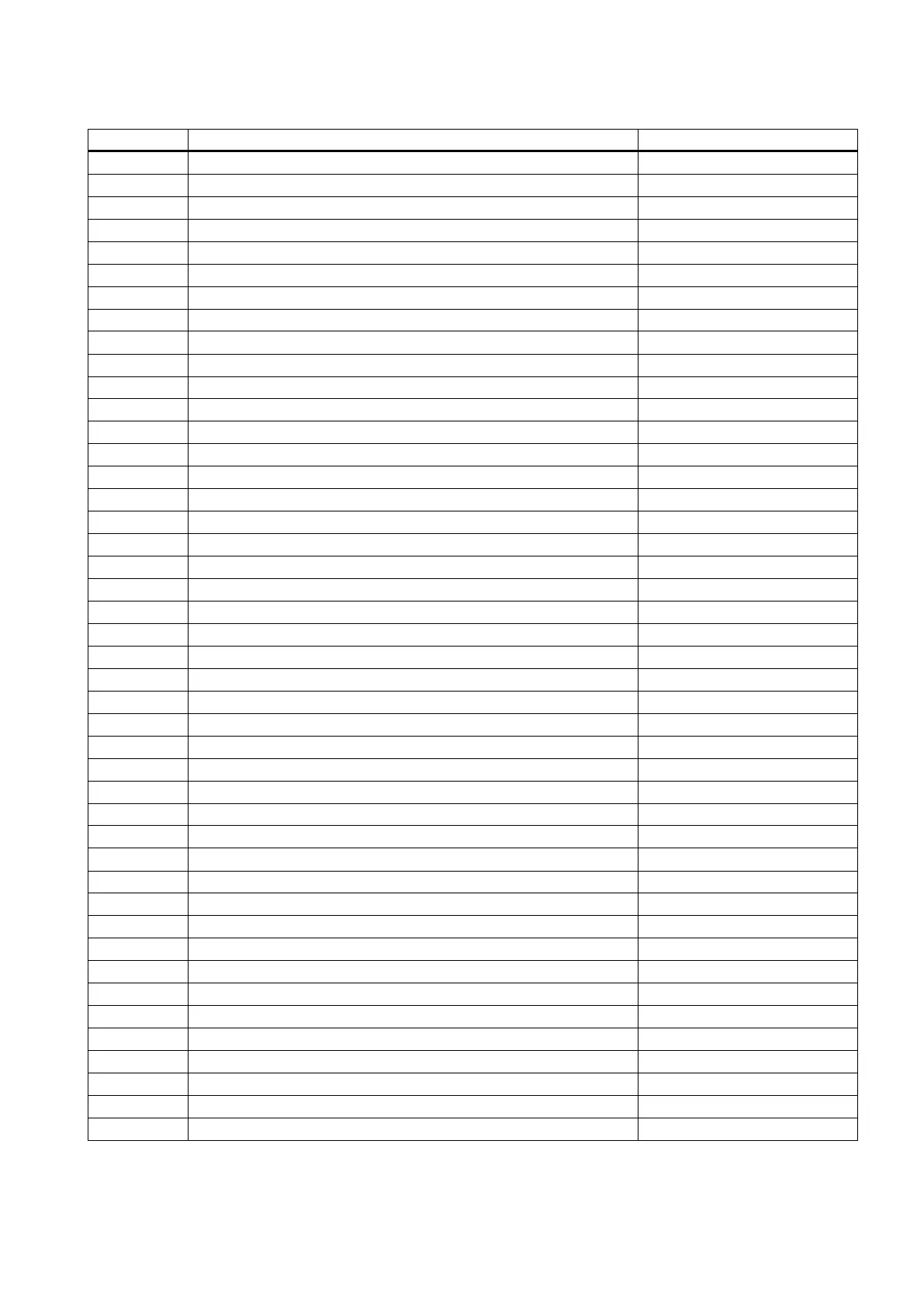

Table 5-1 Assignment of inputs and outputs

I0.0 Emergency Stop button Normally closed

I0.1 Limit switch in the "+" direction of axis X Normally closed

I0.2 Limit switch in the "-" direction of axis X Normally closed

I0.3

I0.4

I0.5 Limit switch in the "+" direction of axis Z Normally closed

I0.6 Limit switch in the "-" direction of axis Z Normally closed

I0.7 Reference point switch of axis X Normally open

I1.0

I1.1 Reference switch of axis Z Normally open

I1.2 Tool path detecting signal T1 Valid at a low level

I1.3 Tool path detecting signal T2 Valid at a low level

I1.4 Tool path detecting signal T3 Valid at a low level

I1.5 Tool path detecting signal T4 Valid at a low level

I1.6 Tool path detecting signal T5 Valid at a low level

I1.7 Tool path detecting signal T6 Valid at a low level

I2.0 Turret motor overload Normally closed

I2.1 Reserved for other types of turrets Reserved

I2.2

I2.3 Chuck foot switch Normally open

I2.4 Coolant level too low Normally closed

I2.5 Cooling pump motor overload Normally closed

I2.6 Lubricant level to low Normally closed

I2.7 Lubrication pump motor overload Normally closed

I3.0 Reserved

I3.1 Reserved

I3.2 Reserved

I3.3 Reserved

I3.4 Reserved

I3.5 Reserved

I3.6 Reserved

I3.7 Reserved

I4.0 Handheld unit: axis X selected Valid at a high level

I4.1 Handheld unit: axis Y selected Valid at a high level

I4.2 Handheld unit: axis Z selected Valid at a high level

I4.3 Handheld unit: fourth axis selected Reserved

I4.4 Handheld unit: increment X1 Valid at a high level

I4.5 Handheld unit: increment X10 Valid at a high level

I4.6 Handheld unit: increment X100 Valid at a high level

I4.7 Handheld unit: enabled Valid at a high level

Q0.0 Working lamp

Q0.1

Q0.2 Tailstock forward

Q0.3 Tailstock backward

Loading...

Loading...