Parameter Manual

Operating Instructions, 08/2013, 6FC5397-8EP40-0BA0

145

Machine data

2.3 Channel-specific machine data

Description: This machine data defines the speed regulation characteristic of the spindle

in G0 blocks with constant cutting rate (G96, G961) selected .

1: In a G0 block, the spindle speed is kept constant at the last value of

the previous block that was unequal G0.

Prior to a subsequent block that does not contain G0, the spindle speed is

increased to a value that belongs to the transverse axis position of the sub-

sequent block.

0: In a G0 block, the spindle speed changes against the transverse axis

position.

Description: Bit 0 = 1:

The M functions for subroutine end (M17 and/or M2/M30) are transferred to the

PLC interface.

Bit 0 = 0:

The M functions for subroutine end (M17 and/or M2/M30) are not transferred to

the PLC interface.

Note:

To prevent stopping in continuous-path mode, M17 must not be programmed alone

in a block.

Example of a subroutine: G64 F2000 G91 Y10 X10

X10 Z10 M17

Bit 1 = 0:

M01:

conditional program stop is always output to PLC, irrespective of whether the

M01 signal is active or not.

Fast auxiliary function output M=QU(1) is inactive because M01 is assigned to

the 1st M function group and thus is always output at block end.

Bit 1 = 1:

M01:

conditional program stop is only output to PLC, if M01 is also active.

This thus enables optimal run-time processing of the part program.

With fast auxiliary function output M=QU(1), M1 is output during the move-

ment; thus it is possible to traverse blocks in continuous-path mode with

programmed M01 as long as M01 is not active.

The request of the M01 signal with M=QU(1) no longer occurs at block end but

during the movement.

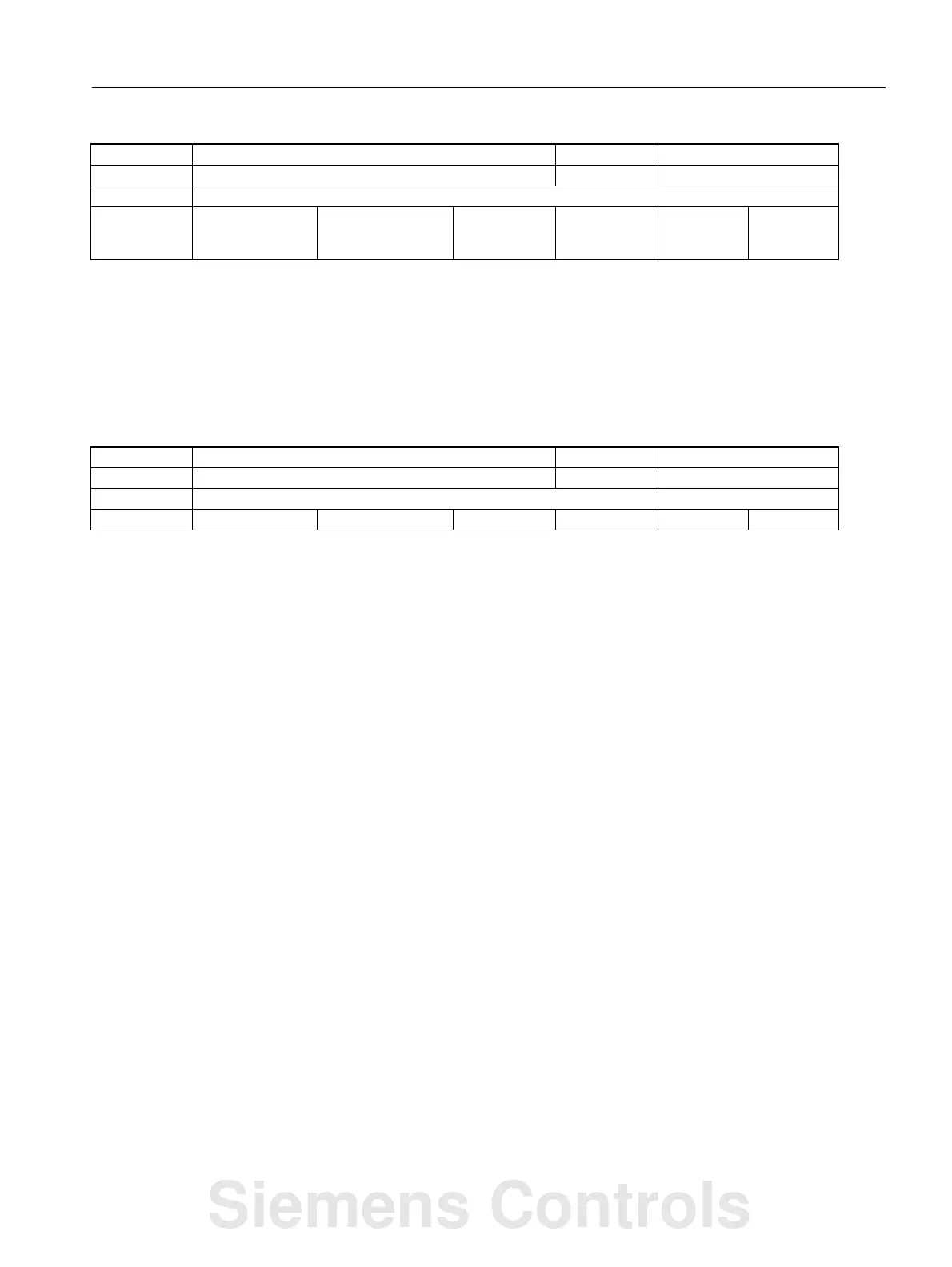

20750 ALLOW_G0_IN_G96 C09, C05 P2,V1

- G0 logic with G96, G961 BOOLEAN PowerOn

-

- - TRUE, TRUE, TRUE,

TRUE, TRUE, TRUE,

TRUE...

0 - 1/1

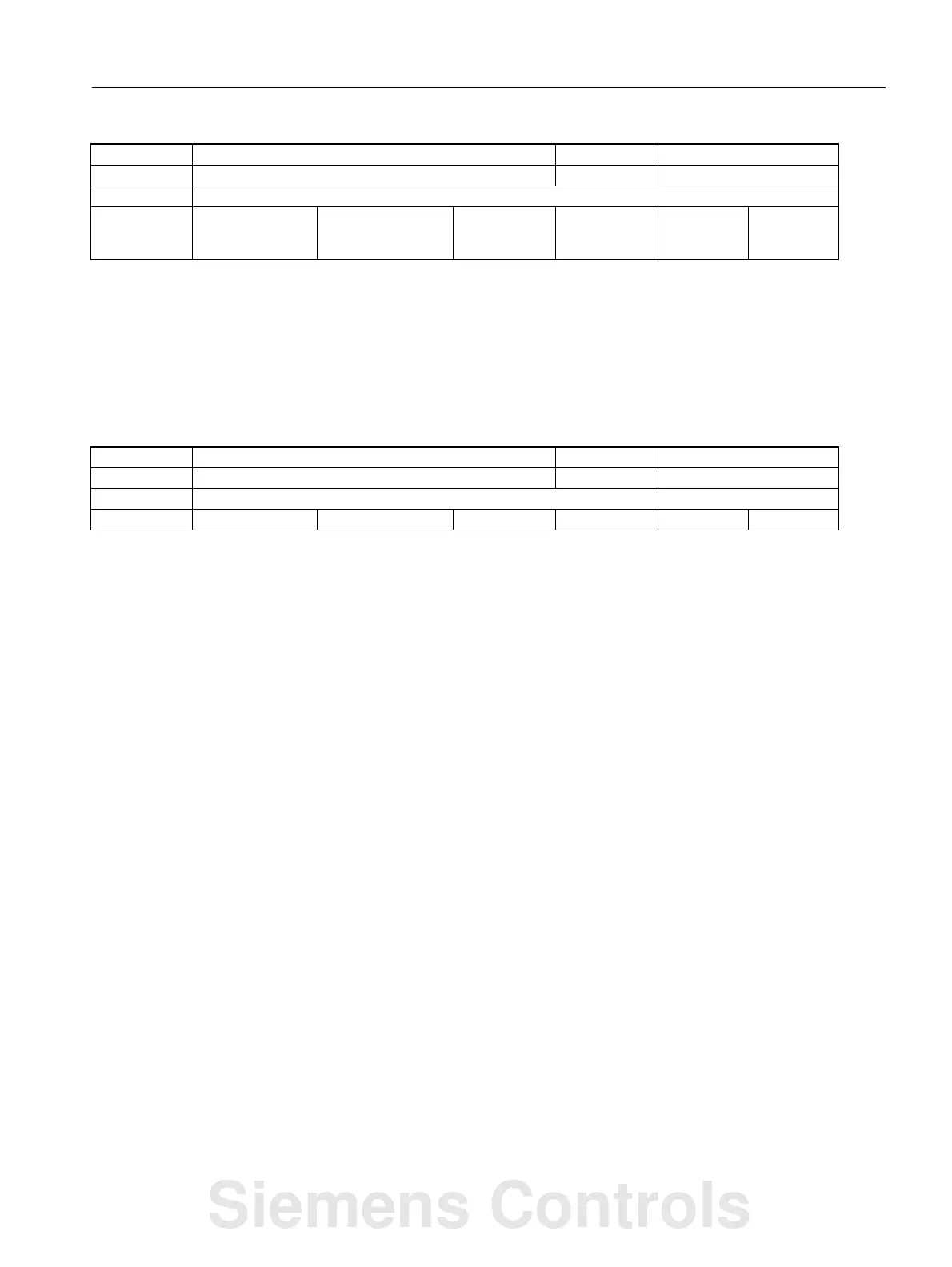

20800 SPF_END_TO_VDI C04, C03 H2,K1

- End of subroutine to PLC BYTE PowerOn

-

- - 1, 1, 1, 1, 1, 1, 1, 1... - - 1/1

Siemens Controls

Loading...

Loading...