NC setting data

Parameter Manual

324

Operating Instructions, 08/2013, 6FC5397-8EP40-0BA0

Description:

Spindle speed at spindle start by NC/PLC interface signals DB380x DBX5006.1

(Spindle start clockwise rotation) and DB380x DBX5006.2 (Spindle start coun-

terclockwise rotation).

Example: SD43200 $SA_SPIND_S[S1] = 600

Spindle 1 is started at a speed of 600 rpm upon detection of the positive

edge of one of the above-mentioned VDI starting signals.

Speed programming values are entered in the SD by setting bit 4=1 in MD35035

$MA_SPIND_FUNCTION_MASK.

The SD becomes active in JOG mode as a default speed by setting bit 5=1 in

MD35035 $MA_SPIND_FUNCTION_MASK (exception: the value is zero).

Related to:

MD35035 $MA_SPIND_FUNCTION_MASK

MD10709 $MN_PROG_SD_POWERON_INIT_TAB

MD10710 $MN_PROG_SD_RESET_SAVE_TAB

Description: Definition of the constant cutting speed for the master spindle.

The setting data is evaluated at spindle start by the NC/PLC interface sig-

nals DB380x DBX5006.1 (Spindle start clockwise rotation) and DB380x DBX5006.2

(Spindle start counterclockwise rotation)

Cutting speed programming values are entered in the SD by setting bit 8=1 in

MD35035 $MA_SPIND_FUNCTION_MASK.

Related to:

MD35035 $MA_SPIND_FUNCTION_MASK

MD10709 $MN_PROG_SD_POWERON_INIT_TAB

MD10710 $MN_PROG_SD_RESET_SAVE_TAB

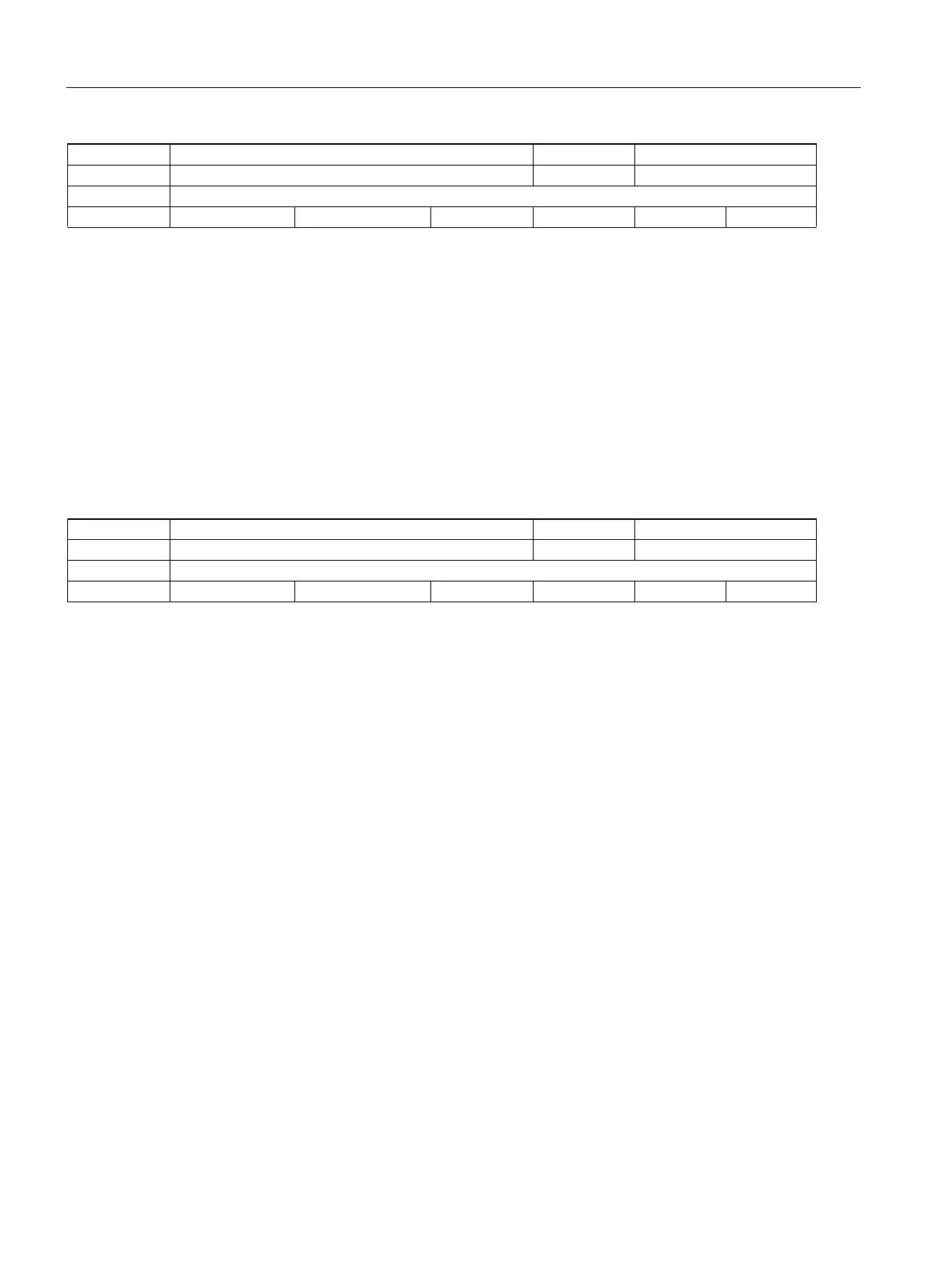

43200 SPIND_S -S1

rev/min Speed for spindle start by VDI DOUBLE Immediately

-

-- 0.0 0.0 - 7/7

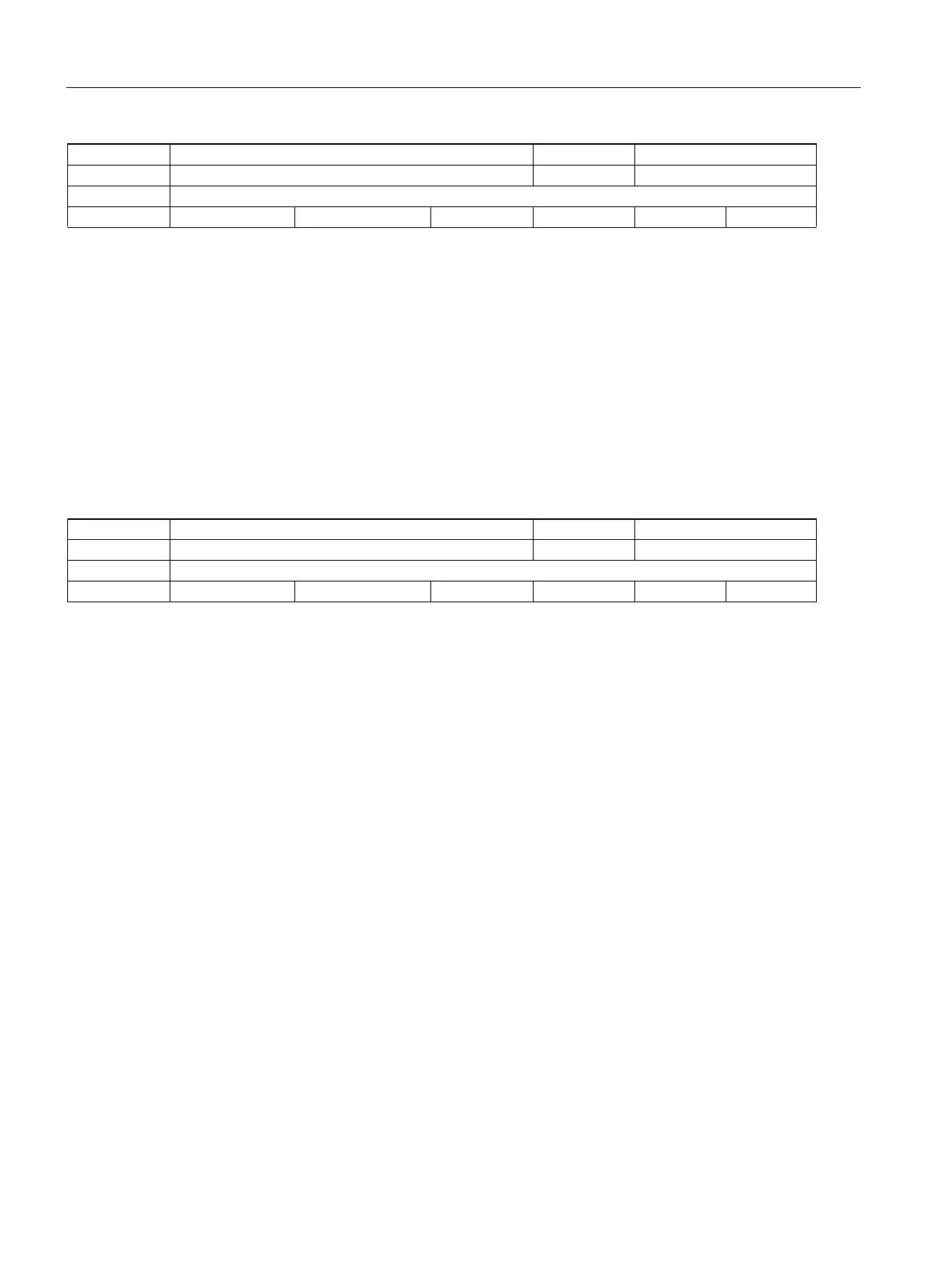

43202 SPIND_CONSTCUT_S -S1

m/min Const cut speed for spindle start by VDI DOUBLE Immediately

-

-- 0.0 0.0 - 7/7

Loading...

Loading...