18

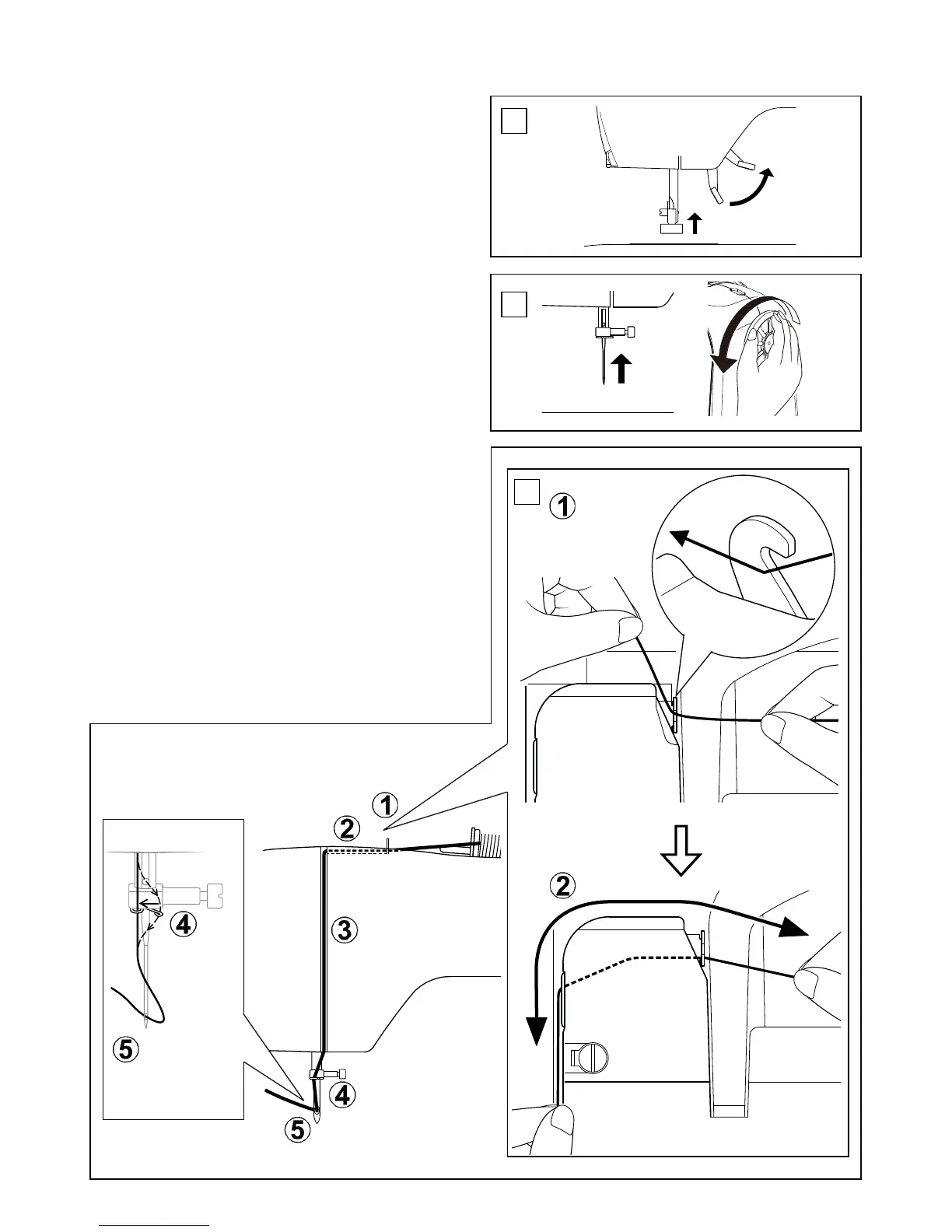

THREADING THE TOP THREAD

$5DLVHWKHSUHVVHUIRRW OLIWHU$OZD\VEHVXUHWRUDLVH WKH

SUHVVHUIRRW OLIWHUEHIRUH WKUHDGLQJWKH WRSWKUHDG,IWKH

presser foot lifter is not raised, correct thread tension

cannot be obtained.)

%7XUQWKHKDQGZKHHOFRXQWHUFORFNZLVHXQWLOWKHQHHGOHLV

LQLWVKLJKHVWSRVLWLRQ

&7KUHDGWKHPDFKLQHZLWK\RXUOHIWKDQGZKLOH¿UPO\JULSSLQJ

WKHWKUHDGZLWK\RXUULJKWKDQGLQWKHIROORZLQJRUGHUDV

illustrated.

*XLGHWKHWKUHDGWKURXJKWKUHDGJXLGHVDQGWKHQ

SXOOLWGRZQDORQJWKHJURRYH

*XLGHWKHWKUHDGLQWRWKHWKUHDGJXLGH

3DVV WKHWKUHDG WKURXJKWKH H\HRI WKHQHHGOH IURP

IURQWWREDFN6HHIROORZLQJSDJHIRULQVWUXFWLRQVRQ

RSHUDWLRQRIWKH$XWRPDWLF1HHGOH7KUHDGHU

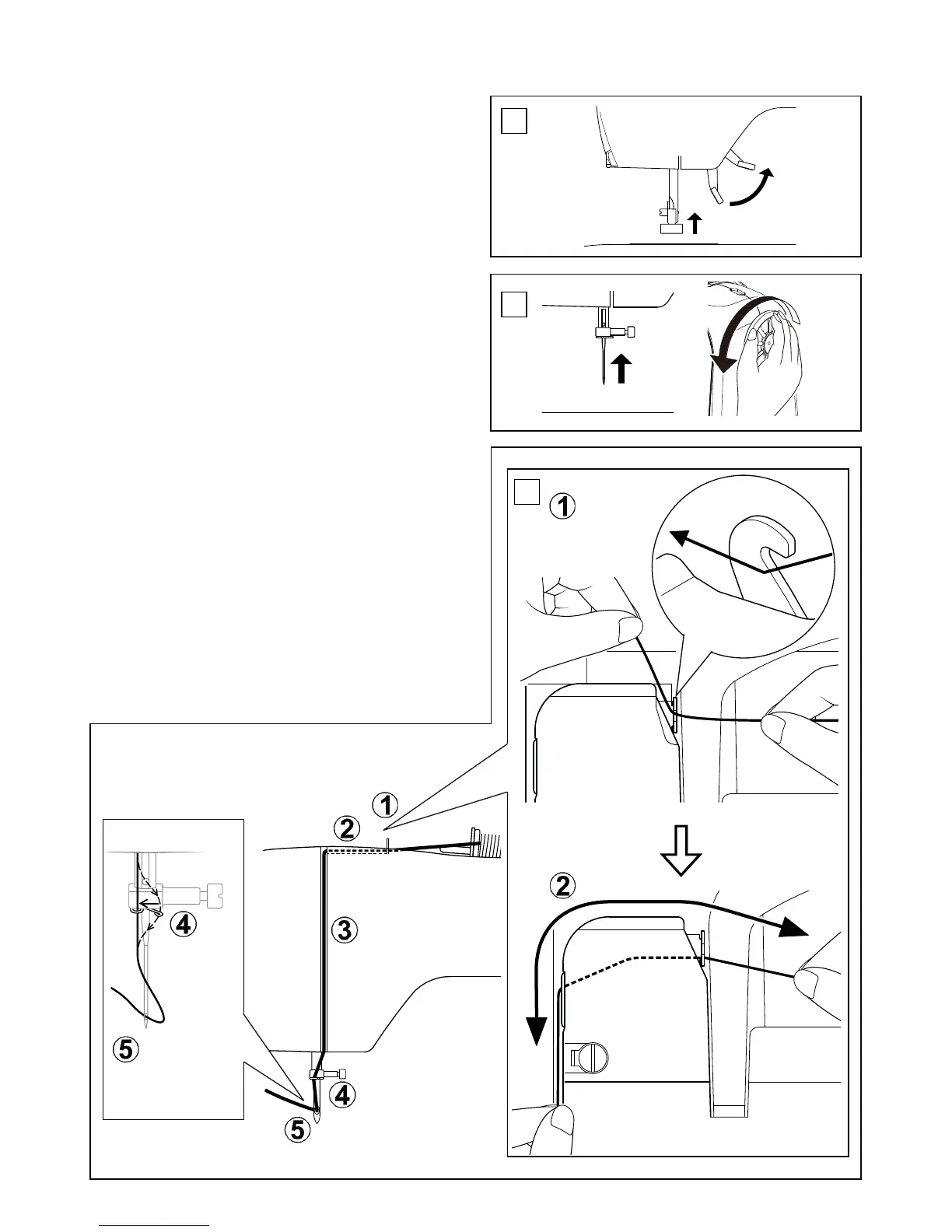

IMPORTANT:

To verify that the machine is threaded properly in the

tension discs, do this simple check:

1.) With the presser foot raised, pull the thread towards

the back of the machine. You should detect only

D VOLJKW UHVLVWDQFH DQG OLWWOH RU QR GHÀHFWLRQ RI WKH

needle.

2.) Now lower the presser foot and again pull the thread

towards the the back of the machine. This time you

should detect a considerable amount of resistance

and much more deflection of the needle. If you do

not detect the resistance you have mis-threaded the

machine and need to re-thread it.

A

B

C

Loading...

Loading...