-50-

No.PF※※-OMJ0006-G

Troubleshooting

Troubleshooting

If an operation failure occurs with the product, use the chart below to find out the cause of the problem.

If none of the countermeasures seem to be applicable, or a replacement product operates normally when

installed, the product may be faulty. A product can be damaged by the operating environment (system

configuration etc). If the product seems to be faulty, please contact SMC.

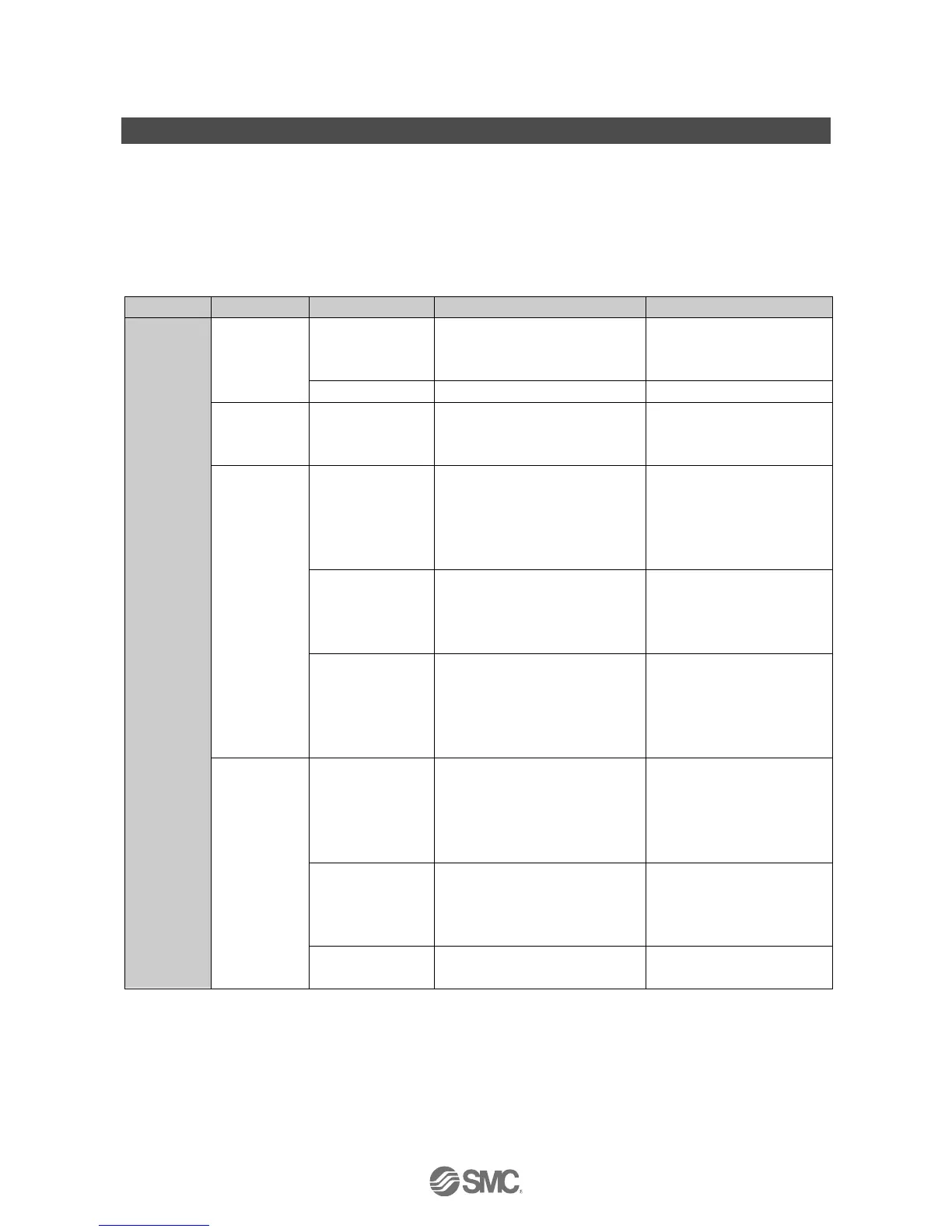

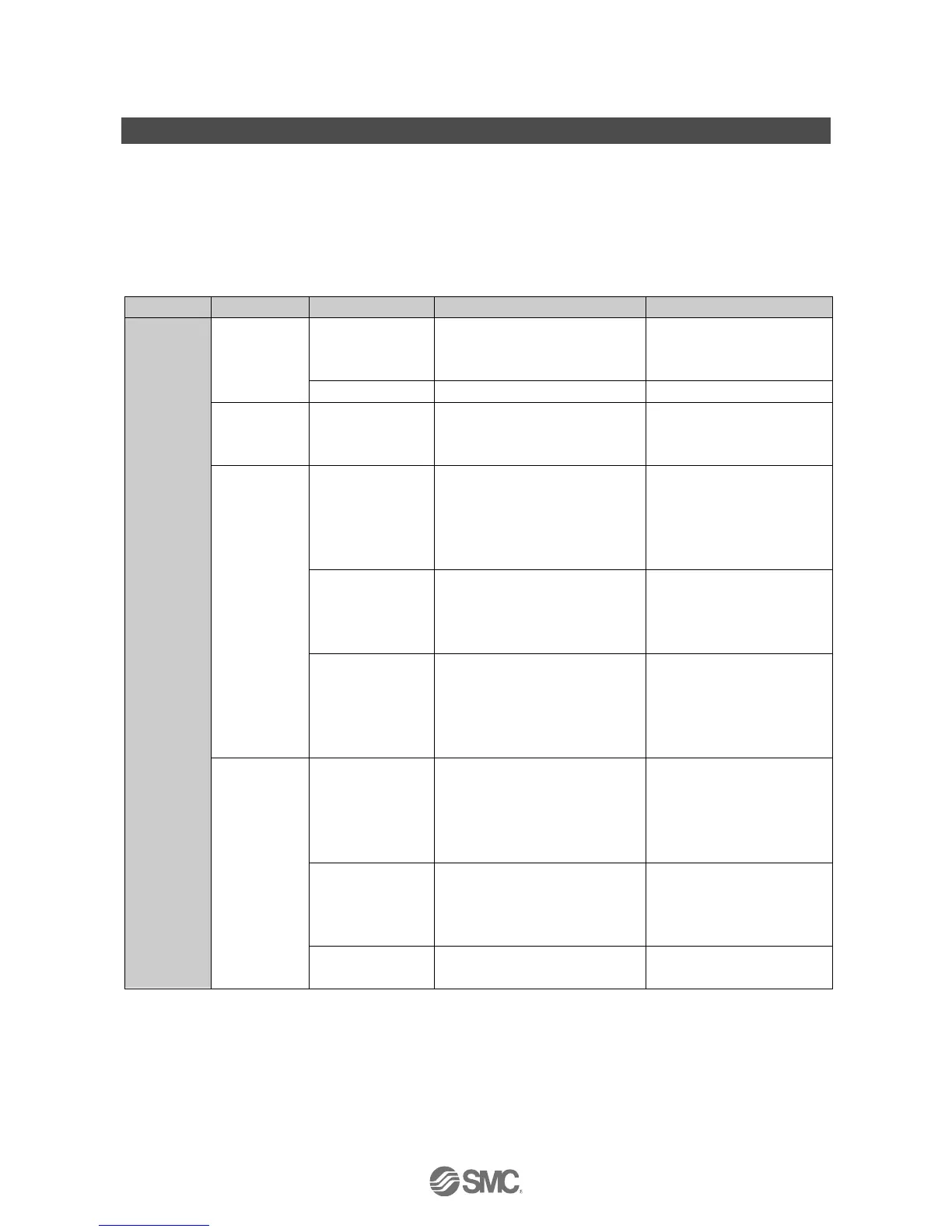

●Faults and countermeasures

Check that the brown and blue

wires are connected to DC (+)

and DC (

-

) respectively.

Correct the connector wiring.

Peak/bottom value

display mode is

selected

Check if the peak value or bottom

value display mode has been

selected.

Refer to "Peak/bottom value

display" (page 45), and

remove the setting.

Foreign matter has

entered the flow

passage or

adhered to the

sensor

(1) Check if any foreign matter

has entered the flow passage.

(2) Check if there is foreign matter

on the mesh.

Install a filter or mist

separator on the IN side.

Piping connected

backwards

Check that the fluid flow is in the

same direction as marked on the

product body.

Ensure the product is

mounted so that the fluid flow

matches the direction marked

on the product body.

Check if there is any supply

pressure fluctuation or pressure

pulsation due to the

characteristics of the source

compressor (or pump).

Install an accumulator tank to

reduce the pressure

fluctuation.

Change the pressure source

to one that has less pulsation.

Foreign matter has

entered the flow

passage or

adhered to the

sensor

(1) Check if any foreign matter

has entered the flow passage.

(2) Check if there is foreign matter

on the mesh.

Install a filter or mist

separator on the IN side.

Piping in the

reverse direction

Check that the fluid flow is in the

same direction as marked on the

product body.

Ensure the product is

mounted so that the fluid flow

matches the direction marked

on the product body.

Incorrect display

units setting

Check the display unit selected.

Select the appropriate units.

Loading...

Loading...