26 MS 290, MS 310, MS 390

– Carry out preparations, b 6.2.1

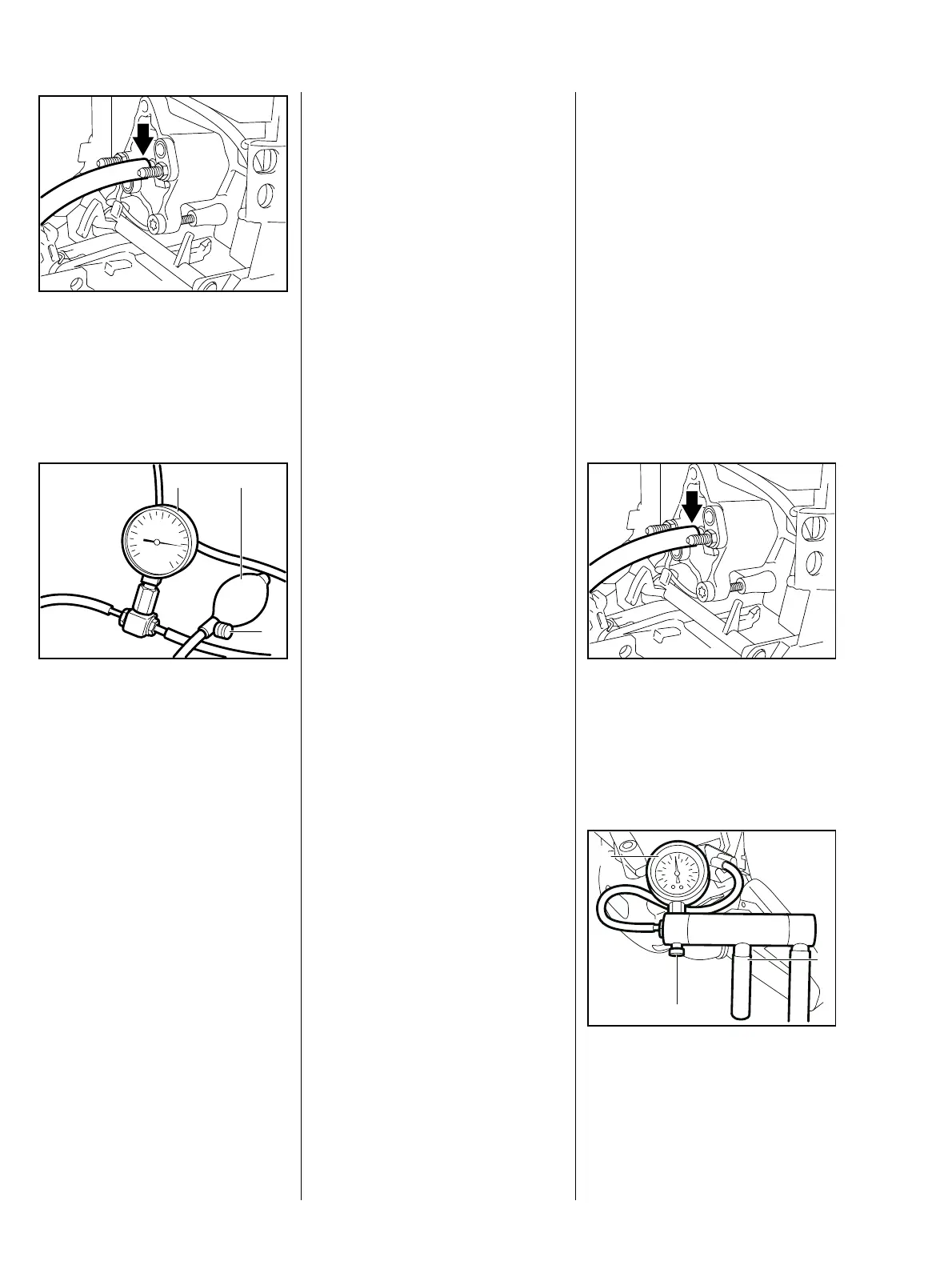

: Connect pressure hose to nipple

(arrow) on test flange.

VA

209RA029

: Close vent screw (1) on the

rubber bulb.

: Pump air into the crankcase with

rubber bulb (2) until the gauge (3)

indicates a pressure of 0.5 bar.

If this pressure remains constant for

VA

249RA012

2

1

3

at least 20 seconds, the crankcase

is airtight.

If the pressure drops, the leak must

be found and the faulty part

replaced.

To find the leak, coat the suspect

area with oil and pressurize the

crankcase again. Bubbles will

appear if a leak exists.

– Repeat the pressure test if

necessary.

– After finishing the test, open the

vent screw and disconnect the

hose.

– Continue with vacuum test,

b 6.2.3

Oil seals tend to fail when subjected

to a vacuum, i.e. the sealing lip lifts

away from the crankshaft during the

piston's induction stroke because

there is no internal counterpressure.

A test can be carried out with the

vacuum pump to detect this kind of

fault.

– Carry out pressure test, b 6.2.2

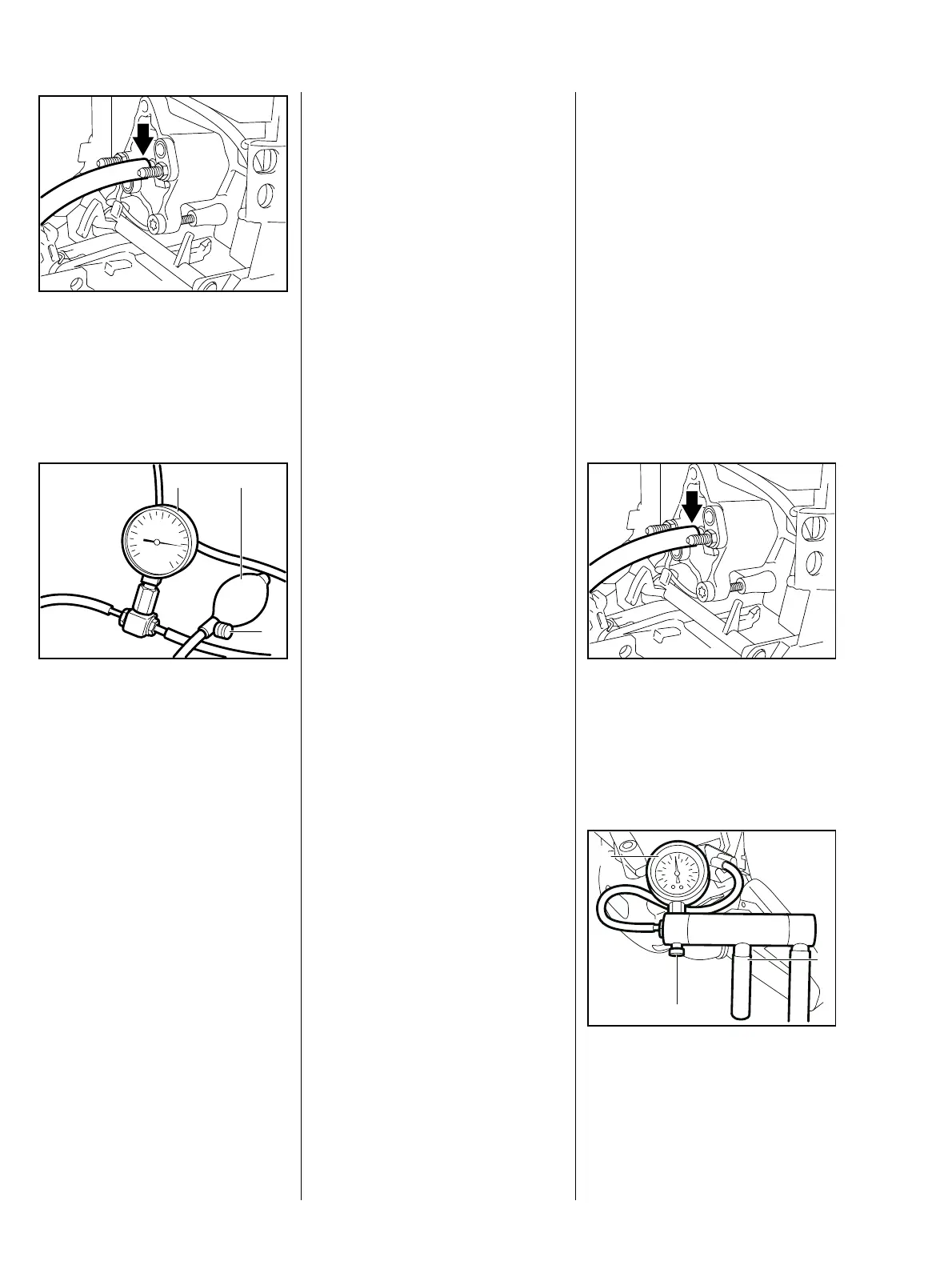

: Connect suction hose of vacuum

pump 0000 850 3501 to nipple

(arrow) of the test flange.

VA

209RA029

: Close the vent screw (1) on the

pump.

: Operate lever (2) until pressure

gauge (3) indicates a vacuum of

0.5 bar.

VA

135RA061

2

1

3

6.2.2 Pressure Test 6.2.3 Vacuum Test

Loading...

Loading...