68 MS 290, MS 310, MS 390

The diaphragm material as well as

the inlet and outlet valves are

subjected to continuous alternating

stresses and eventually show signs

of fatigue, i.e. the diaphragm

distorts and swells and has to be

replaced.

Install in the reverse sequence.

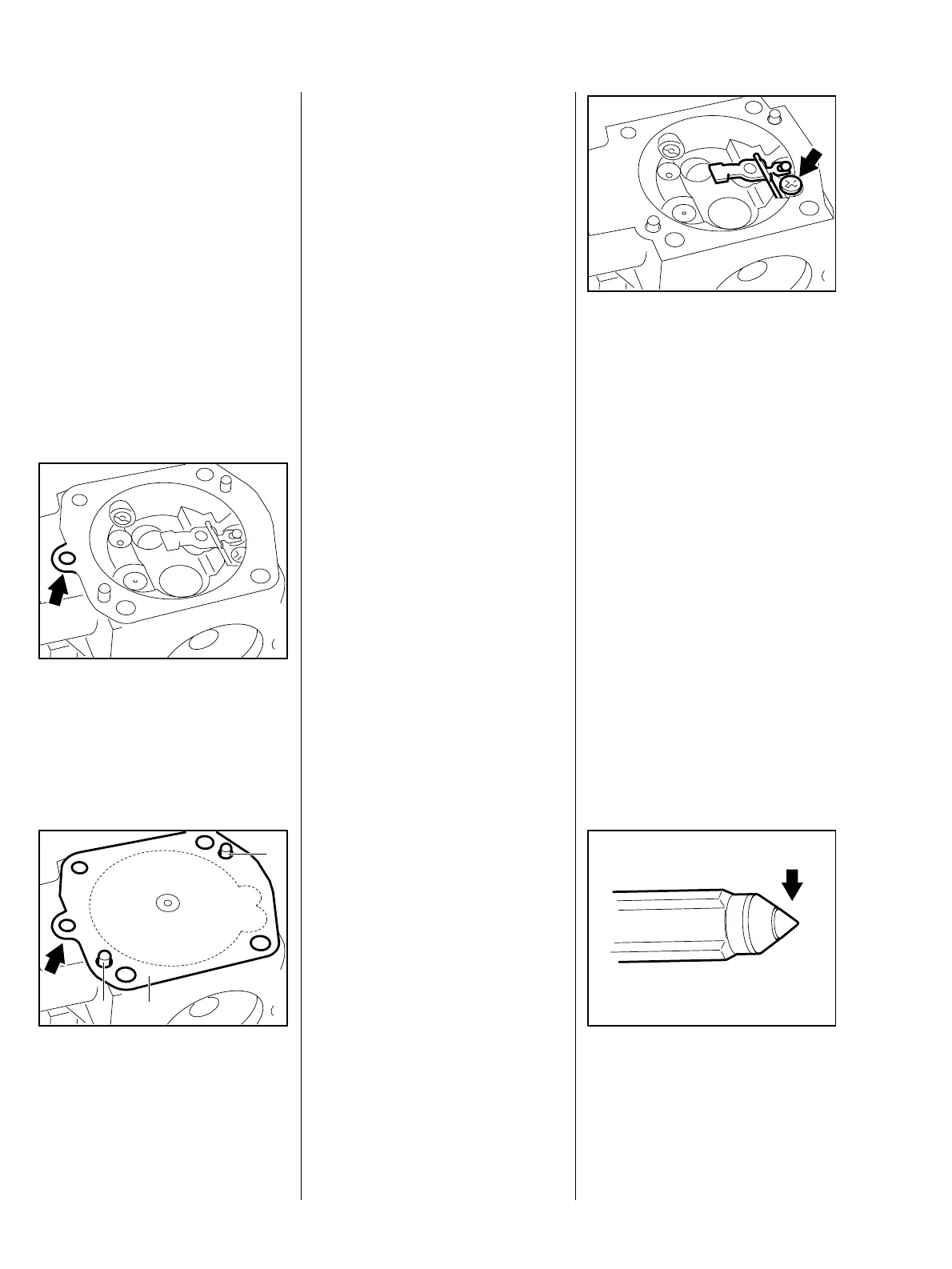

: Place the gasket on the

carburetor body so that the tab

(arrow) points towards the

adjusting screws.

VA

212RA160

: Fit the metering diaphragm (1) on

the carburetor body so that the

perforated plate faces the inlet

control lever and the tab (arrow)

points towards the adjusting

screws.

VA

212RA161

1

2

3

The gasket and metering

diaphragm are held in position by

integrally cast pegs (2+3).

– Fit the end cover.

– Fit screws and tighten them down

firmly, b 3.5

Install all other parts in the reverse

sequence.

– Remove the metering

diaphragm, b 11.3.1

: Take out the screw (arrow).

– Remove the inlet control lever

with spindle.

VA

212RA162

There is a small spring under the

inlet control lever which may pop

out during disassembly.

– Take out the inlet needle.

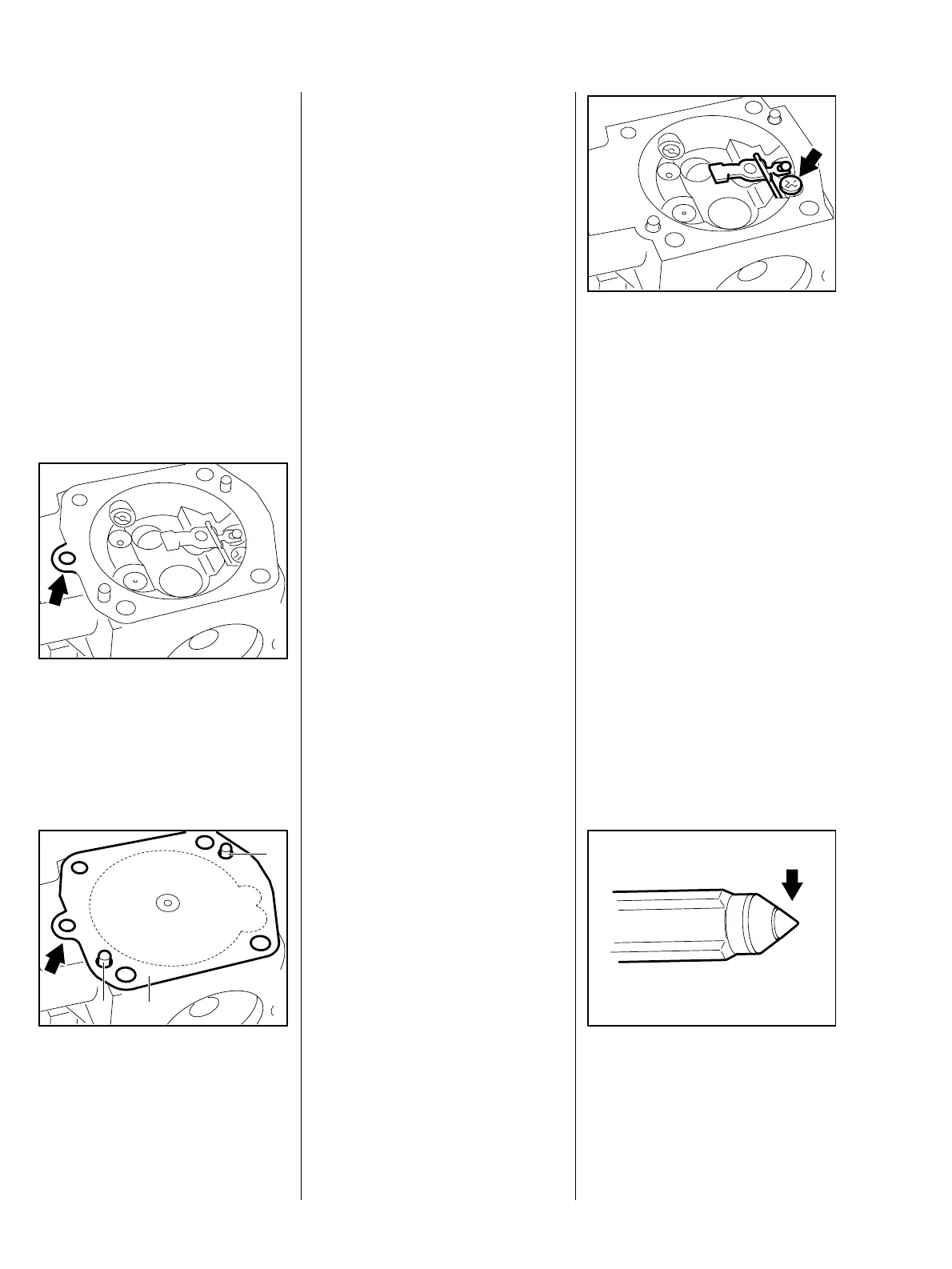

: If there is an annular indentation

on the sealing cone of the inlet

needle, fit a new inlet needle.

VA

146RA149

11.3.2 Inlet Needle

Loading...

Loading...