75MS 290, MS 310, MS 390

– Drain the fuel tank.

– Clean loose dirt from the air filter

and the area around it.

– Remove the air filter, b 11.1

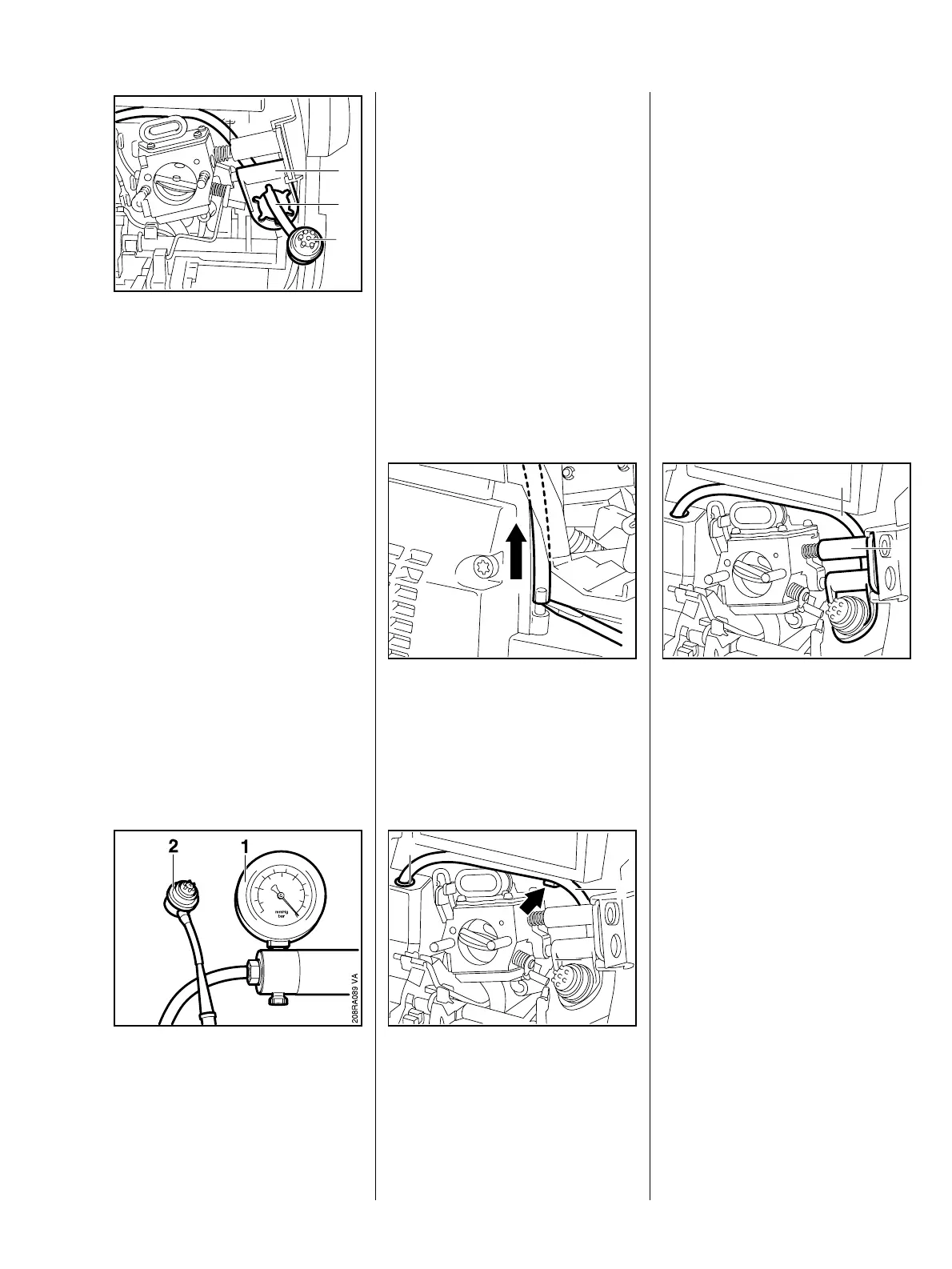

: Pull tank vent valve (1) out of the

209RA047

VA

2

3

1

retainer (2) and off the hose (3).

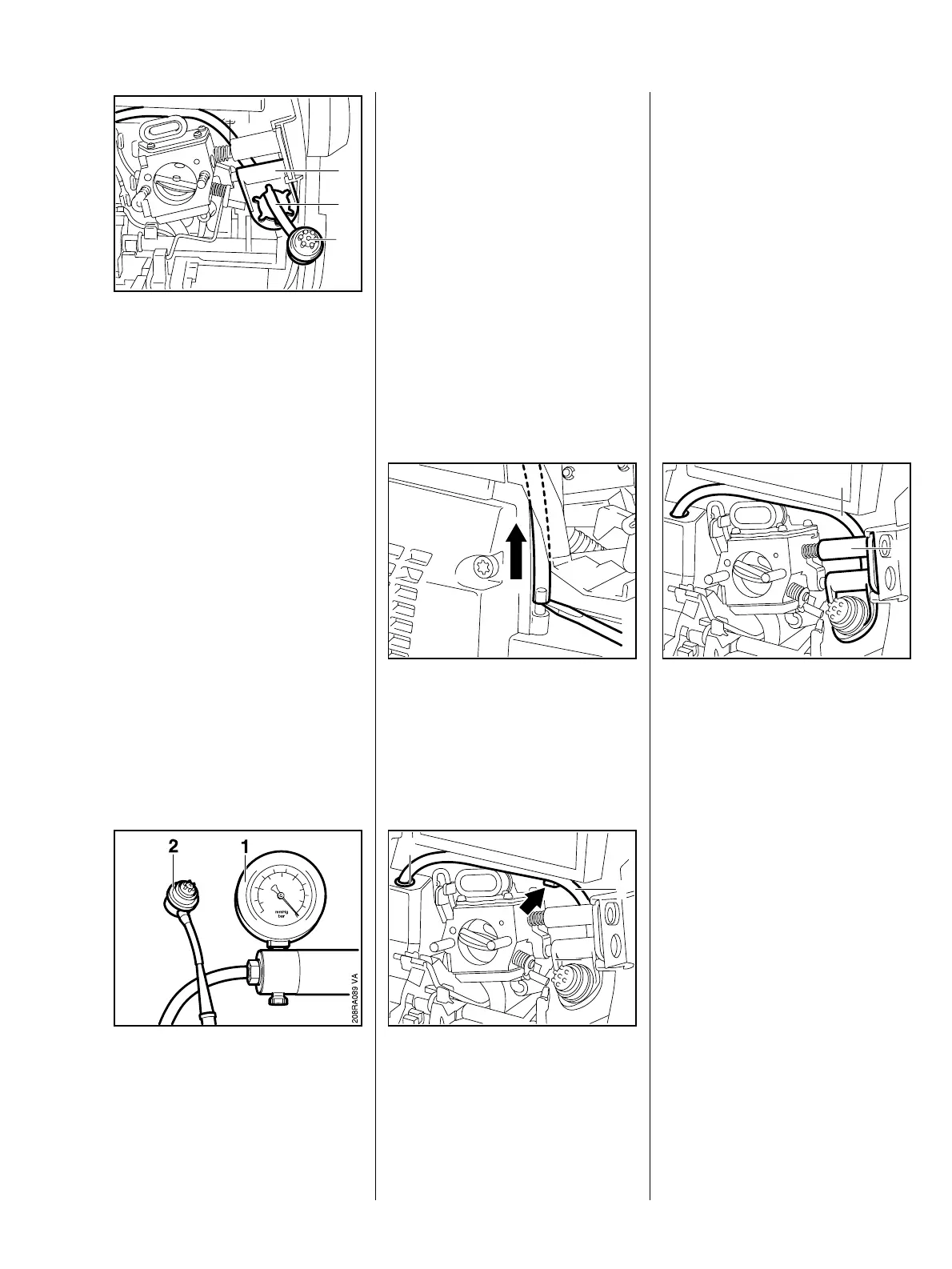

: Connect vacuum pump

0000 850 3501 (1) with hose to

tank vent (2).

– Use vacuum pump to subject

tank vent valve to vacuum.

Equalization of pressure in the fuel

tank takes place via the tank vent

valve. There must be no build-up of

vacuum during the test. In the event

of a malfunction, install a new tank

vent.

: Pry the hose off the engine

housing nipple.

VA

209RA059

: Pry the grommet (1) out of the

handle housing.

: Take the hose (2) out of the

retainer (arrow).

VA

209RA058

1

2

– Remove the hose.

Clean the hose with compressed air

and a little standard solvent-based

degreasant containing no

chlorinated or halogenated

hydrocarbons, b 13.

Inspect components for damage

and cracks and replace if

necessary.

Install in the reverse sequence.

: Position the hose (1) behind the

grommet (2).

Fit the tank vent in the grommet so

that its stub points upwards.

Make sure the hoses are not kinked.

209RA060

VA

1

2

Install all other parts in the reverse

sequence.

11.5.2 Machines from 2002

Loading...

Loading...