Performance Check Procedure—2215A Service

TRIGGER

Equipment Required (see Table 4-1):

Leveled Sine-Wave Generator (Item 2) 50-fi BNC Termination (Item 5)

50-fi BNC Cable (Item 4)

INITIAL CONTROL SETTINGS b. Set the generator to produce a 5-MHz, 3-division

display.

Vertical

POSITION (both)

Midrange

VERTICAL MODE

CH 1

BW LIMIT

Off (button out)

CH 1 VOLTS/DIV

5 mV

CH 2 VOLTS/DIV 50 mV

VOLTS/DIV Variable

(both)

CAL detent

INVERT

Off (button out)

Input Coupling (both)

DC

srizontal

POSITION

Midrange

HORIZONTAL MODE A

A and B SEC/DIV

0.2

ns

SEC/DIV Variable

CAL detent

X I0 Magnifier Off (knob in)

B DELAY TIME POSITION

Fully counterclockwise

TRIGGER

SLOPE OUT

LEVEL Midrange

TRIGGER

VAR HOLDOFF

NORM

Mode

P-P AUTO

SLOPE

OUT

LEVEL Midrange

A&B INT CH 1

A SOURCE INT

A EXT COUPLING

DC

PROCEDURE STEPS

1. Check Internal Triggering

a. Connect the leveled sine-wave generator output via a

50-fi cable and a 50-fi termination to the CH 1 OR X input

connector.

c. Set the CH 1 VOLTS/DIV switch to 50 mV.

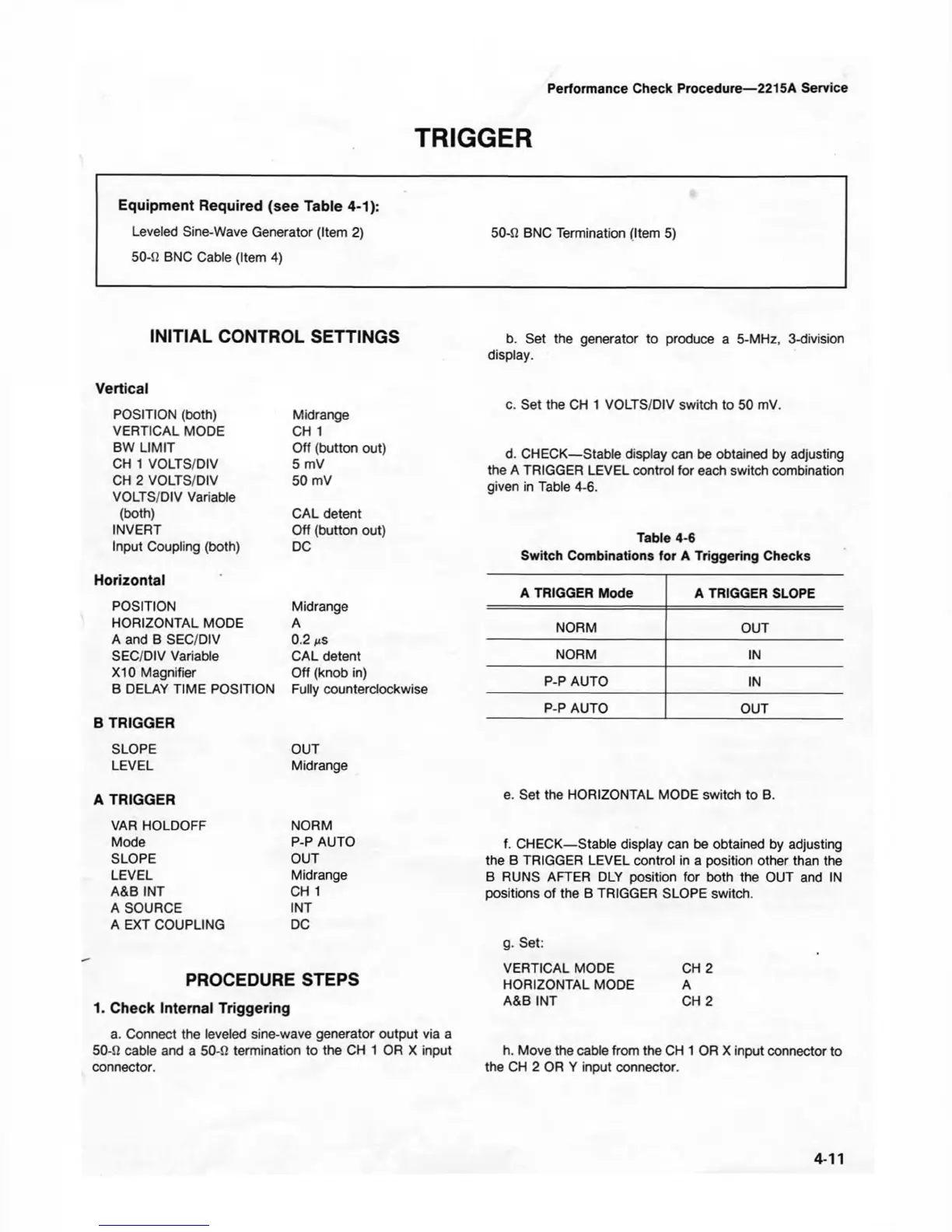

d. CHECK— Stable display can be obtained by adjusting

the A TRIGGER LEVEL control for each switch combination

given in Table 4-6.

Table 4-6

Switch Combinations for A Triggering Checks

A TRIGGER Mode

A TRIGGER SLOPE

NORM OUT

NORM

IN

P-P AUTO IN

P-P AUTO OUT

e. Set the HORIZONTAL MODE switch to B.

f. CHECK—Stable display can be obtained by adjusting

the B TRIGGER LEVEL control in a position other than the

B RUNS AFTER DLY position for both the OUT and IN

positions of the B TRIGGER SLOPE switch.

g. Set:

VERTICAL MODE CH 2

HORIZONTAL MODE A

A&B INT CH 2

h. Move the cable from the CH 1 OR X input connector to

the CH 2 OR Y input connector.

4-11