Adjustment Procedure—2215A Service

POWER SUPPLY AND CRT DISPLAY

Equipment Required (See Table 4-1):

Leveled Sine-Wave Generator (Item 2) Digital Voltmeter (Item 10)

Time-Mark Generator (Item 3) DC Voltmeter (Item 12)

50-0 BNC Cable (Item 4)

Screwdriver (Item 13)

50-0 BNC Termination (Item 5)

See

ADJUSTMENT LOCATIONSS I

a t the back o f this m anual fo r location o f test points and adjustm ents.

INITIAL CONTROL SETTINGS

Vertical

POSITION (both)

Midrange

VERTICAL MODE

CH 1

CH 1 VOLTS/DIV

10 mV

CH 1 VOLTS/DIV Variable

CAL detent

Channel 1 Input Coupling

GND

srizontal

POSITION

Midrange

HORIZONTAL MODE

A

A SEC/DIV

X-Y

SEC/DIV Variable

CAL detent

X I0 Magnifier

Off (knob in)

TRIGGER

VAR HOLDOFF

NORM

Mode

P-P AUTO

SLOPE

OUT

LEVEL

Midrange

A&B INT

VERT MODE

A SOURCE

INT

PROCEDURE STEPS

1. Check/Adjust Power Supply DC Levels (R938)

a. Connect the digital voltmeter low lead to chassis

ground and connect the volts lead to the -8.6-V supply

(TP961).

b. CHECK—Voltmeter reading is —8.56 to -8.64 V. If

the reading is within these limits, skip to part d.

c. ADJUST—The —8.6 V Adj potentiometer (R938) for a

voltmeter reading of -8.60 V.

d. CHECK—Voltage levels of the remaining power sup

plies listed in Table 5-2 are within the specified limits.

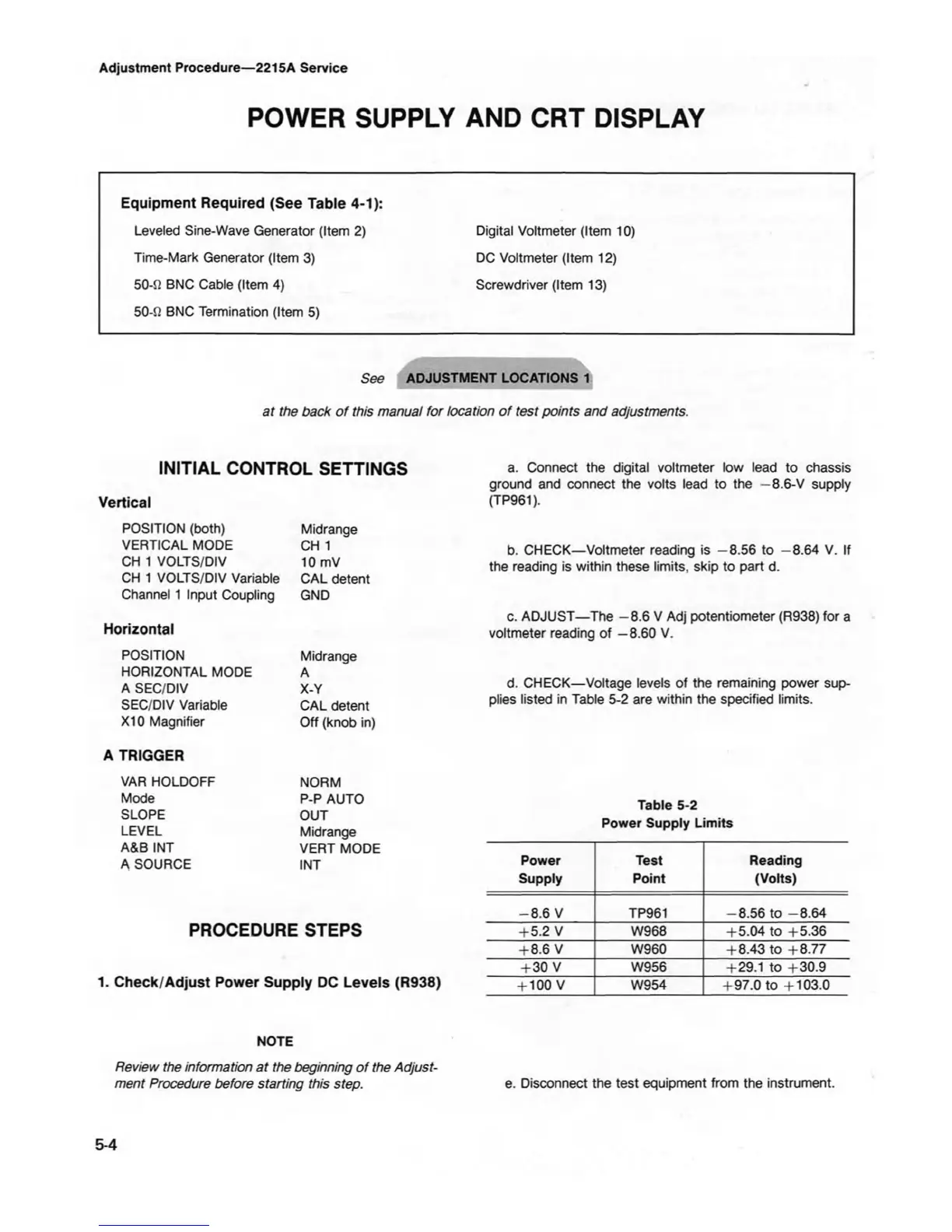

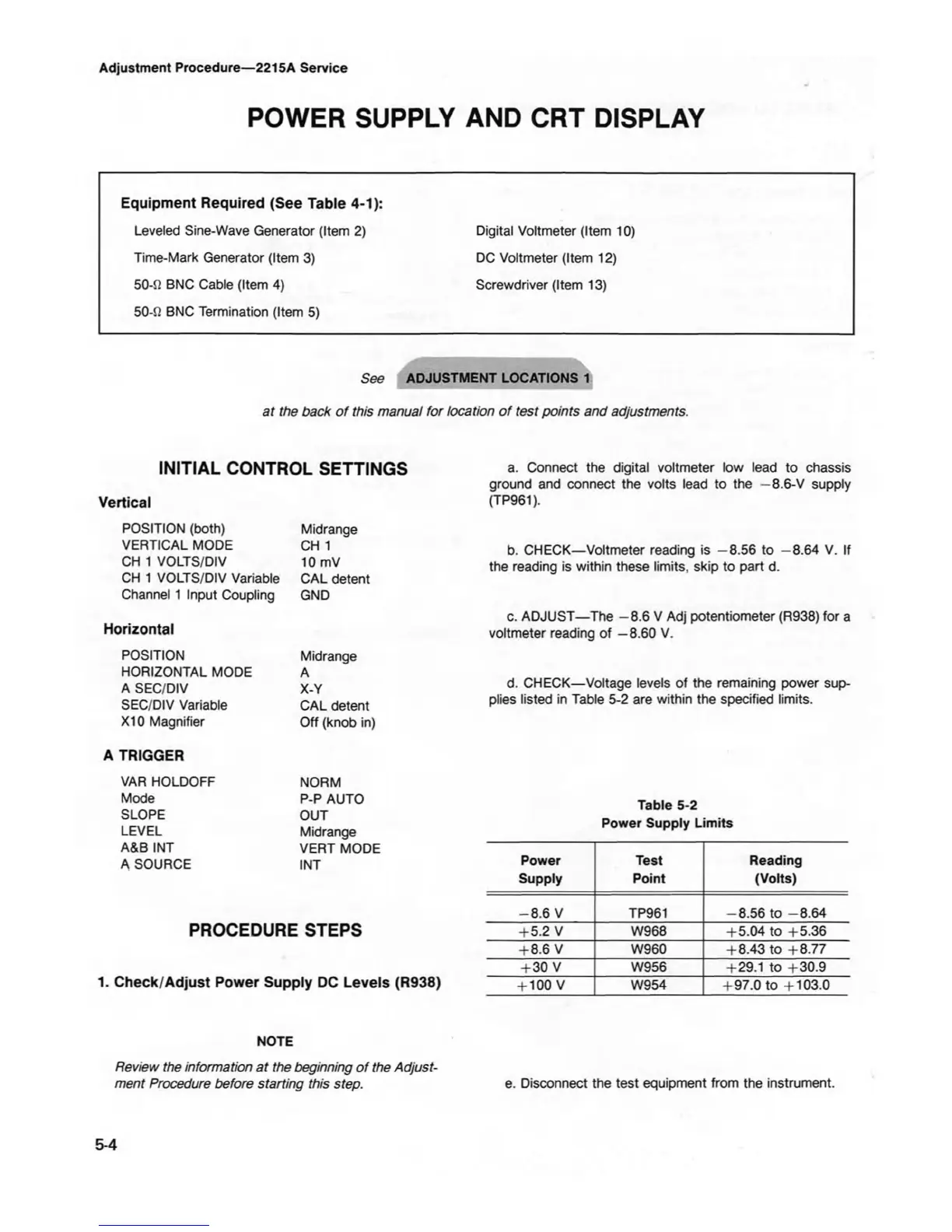

Table 5-2

Power Supply Limits

Power

Test

Reading

Supply Point (Volts)

-8 .6 V

TP961

-8.56 to -8.64

+ 5.2 V W968 + 5.04 to +5.36

+ 8.6 V

W960 + 8.43 to +8.77

+ 30 V

W956 +29.1 to +30.9

+ 100 V

W954

+ 97.0 to +103.0

NOTE

Review the information a t the beginning o f the Adjust

m ent Procedure before starting this step.

5-4

e. Disconnect the test equipment from the instrument.

Loading...

Loading...