Maintenance—485/R485 Service

5. Variable Autotransformer

Description: Output variable from 0 to 140 volts, 10

amperes minimum rating. Must have three-wire power cord,

plug, and receptacle.

Purpose: To vary the input line voltage when trouble

shooting in the power supply.

Recommended type: General Radio W10MT3W Metered

Variac Autotransformer.

Troubleshooting Techniques

IMPORTANT

Special techniques are required to safely troubleshoot

certain areas o f this instrument. Read Trouble

shooting Techniques and Special Troubleshooting

Information completely before beginning actual

troubleshooting.

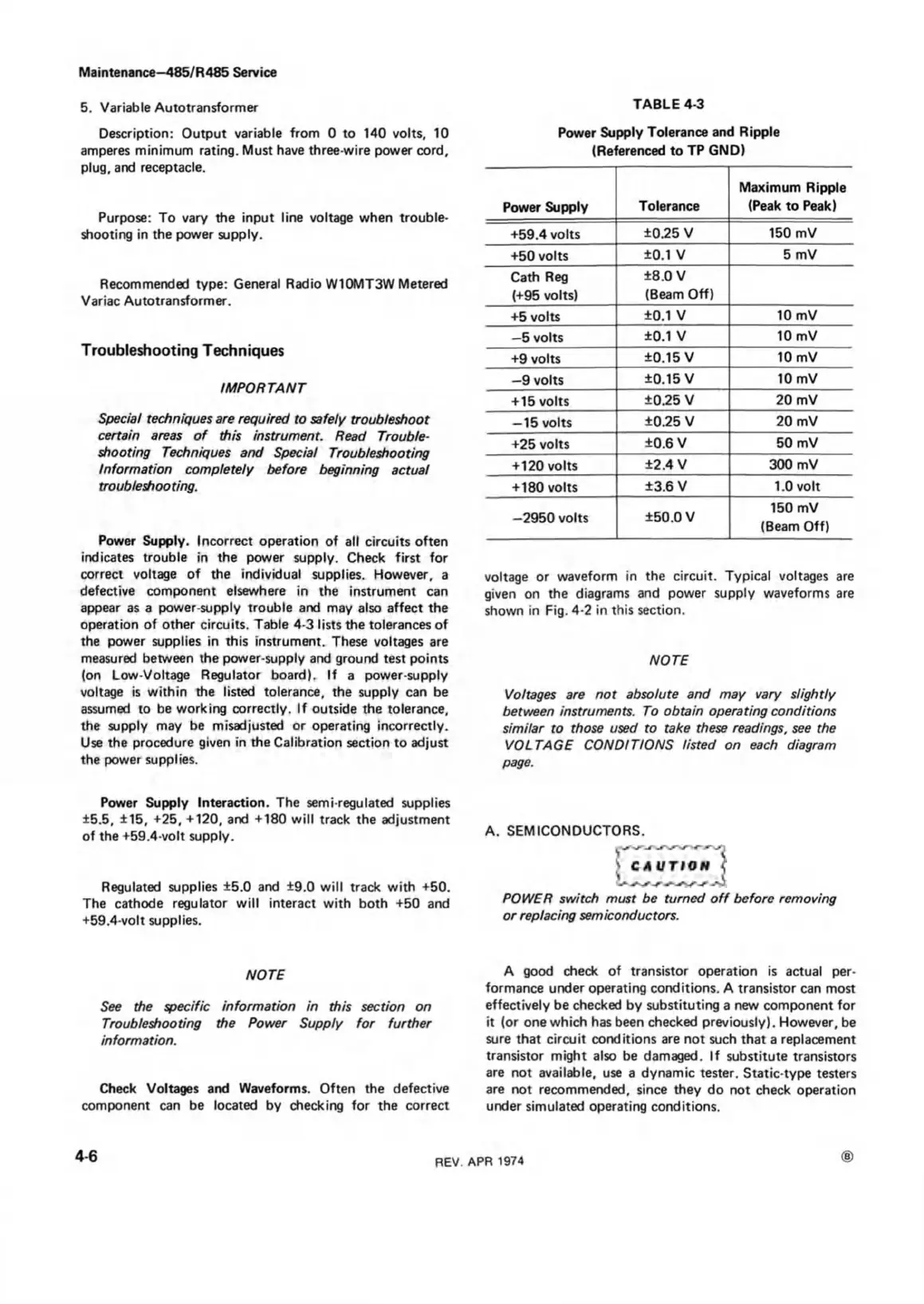

Power Supply. Incorrect operation of all circuits often

indicates trouble in the power supply. Check first for

correct voltage of the individual supplies. However, a

defective component elsewhere in the instrument can

appear as a power-supply trouble and may also affect the

operation of other circuits. Table 4-3 lists the tolerances of

the power supplies in this instrument. These voltages are

measured between the power-supply and ground test points

(on Low-Voltage Regulator board). If a power-supply

voltage is within the listed tolerance, the supply can be

assumed to be working correctly. If outside the tolerance,

the supply may be misadjusted or operating incorrectly.

Use the procedure given in the Calibration section to adjust

the power supplies.

Power Supply Interaction. The semi-regulated supplies

±5.5, ±15, +25, +120, and +180 will track the adjustment

of the +59.4-volt supply.

Regulated supplies ±5.0 and ±9.0 will track with +50.

The cathode regulator will interact with both +50 and

+59.4-volt supplies.

NOTE

See the specific inform ation in this section on

Troubleshooting the Power Supply for further

information.

Check Voltages and Waveforms. Often the defective

component can be located by checking for the correct

TABLE 4-3

Power Supply Tolerance and Ripple

(Referenced to TP GND)

Power Supply

Tolerance

Maximum Ripple

(Peak to Peak)

+59.4 volts

±0.25 V 150 mV

+50 volts

±0.1 V

5 mV

Cath Reg

(+95 volts)

±8.0 V

(Beam Off)

+5 volts

±0.1 V

10 mV

—5 volts

±0.1 V

10 mV

+9 volts

±0.15 V

10 mV

—9 volts

+0.15 V

10 mV

+ 15 volts

±0.25 V 20 mV

— 15 volts

±0.25 V 20 mV

+25 volts

±0.6 V 50 mV

+120 volts

±2.4 V 300 mV

+ 180 volts

±3.6 V 1.0 volt

—2950 volts

±50.0 V

150 mV

(Beam Off)

voltage or waveform in the circuit. Typical voltages are

given on the diagrams and power supply waveforms are

shown in Fig. 4-2 in this section.

NOTE

Voltages are not absolute and may vary slightly

between instruments. To obtain operating conditions

similar to those used to take these readings, see the

VOLTAGE CONDITIONS listed on each diagram

page.

A. SEMICONDUCTORS.

POWER switch must be turned o ff before removing

or replacing semiconductors.

A good check of transistor operation is actual per

formance under operating conditions. A transistor can most

effectively be checked by substituting a new component for

it (or one which has been checked previously). However, be

sure that circuit conditions are not such that a replacement

transistor might also be damaged. If substitute transistors

are not available, use a dynamic tester. Static-type testers

are not recommended, since they do not check operation

under simulated operating conditions.

4-6

REV. APR 1974

Loading...

Loading...