13

4. The display ‘GE24’ starts to blink.

5. When the display stops blinking, the

setting is modied.

To change from GEL to Lead-Acid,

repeat the procedure pressing button

(2) instead of button (3).

ATTENTION:

As the machine is a 24V model, do not

set the batteries at 36V.

HOUR METER

The machine is equipped with an hour

meter located on the same display (1)

of the battery charge level indicator.

Keeping the button (2) pressed, the

rst data indicates the working hours

and after a few seconds the working

minutes are shown.

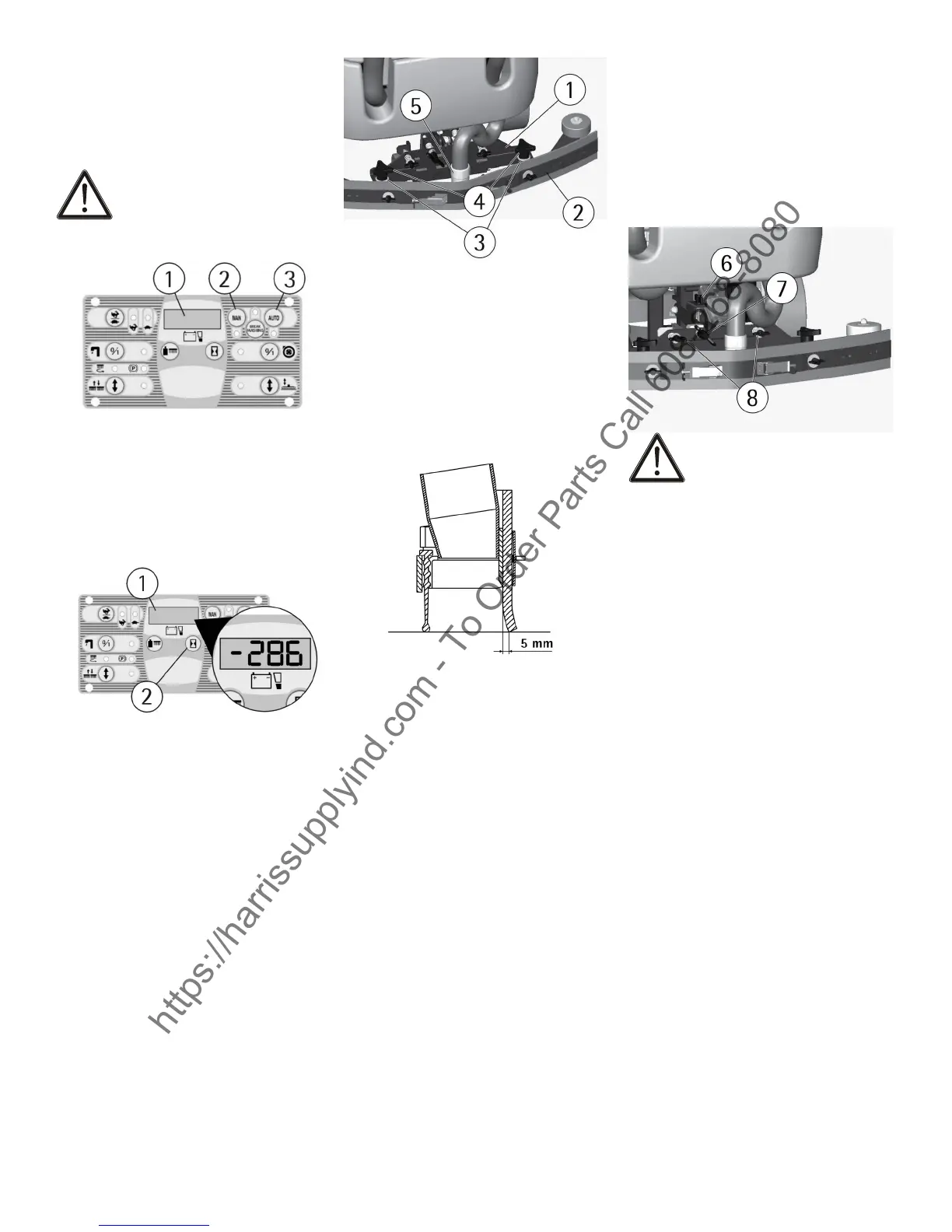

SQUEEGEE ASSEMBLY

1. Hold the squeegee support (1) lifted

from the oor.

2. Insert the threaded parts of the two

knobs (4) making them slide inside

the two slots on the support placed on

the upper part of the squeegee (2).

3. Put the washers (3) into position,

there are two for each knob, so that

they are assembled one under and

the other on top of the two slots on the

support.

4. Secure the squeegee by rotating

the two knobs (4) clockwise.

5. Insert the squeegee hose (5) into

its coupling, as indicated in the gure.

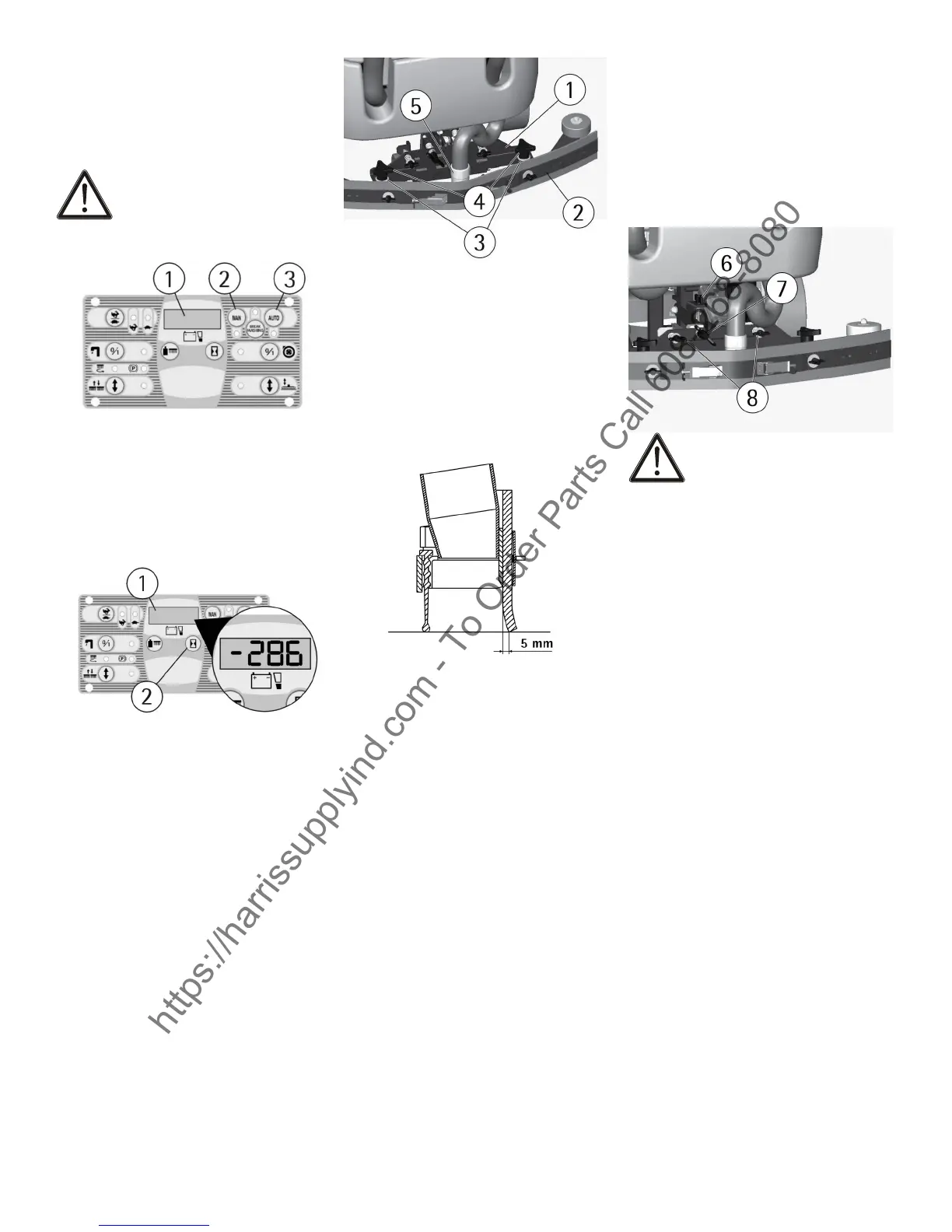

ADJUSTMENT OF THE SQUEEGEE

In order to have a perfect drying

result through the squeegee, the rear

rubber must have the lower bending

uniformly adjusted in all its length. For

the adjustment, it is necessary to put

the machine in working condition and

the vacuum motor has to be switched

on and the brushes have to function

together with the detergent solution.

The lower part of the rubber is too

much bent

Take off the pressure rotating the wing

nut (6) counterclockwise.

The lower part of the rubber is not

much bent

Increase the pressure rotating the

wing nut (6) clockwise. Check that

the wheels which adjust the height

do not rest on the oor, in this case

adjust them as indicated in paragraph

"Height adjustment".

The bending is not uniform

Adjust the squeegee inclination rotat-

ing counterclockwise the wing nut (7)

to increase the bending in the central

part, or clockwise to increase the

bending on the extremities.

Height adjustment

Once that the pressure and inclination

of the squeegee have been adjusted,

it is necessary to x this optimum con-

dition making touch slightly the wheels

onto the oor. Rotate the registers

(8): clockwise to lower the wheels or

counterclockwise to raise them. Both

wheels must be adjusted in the same

measure.

ATTENTION:

Every type of oor requires a specic

adjustment. For example, concrete

oors (where the friction results to

be high) need little pressure, while

smooth oors (ceramics) need higher

pressure.

If the cleaning operations are made

always on the same type of oor, the

adjustment can change only in func-

tion of the rubber wear.

SPLASH GUARD ASSEMBLY

The two splash guards have to be as-

sembled onto the brushes base group

as indicated in the following gures.

Insert the metal strips inside the

suitable slots present on the rubber.

Place the round hole at the extrem-

ity of the strip onto the pin (1) placed

in the front part of the brushes base

group. Secure the strips through the

nut blocking it.

Block the coupling lever (2) in the

rear part of the brushes base group

to the ring placed at the extremity of

the metal strip still free. Please act as

above for both splash guard rubbers.

With the brushes assembled, the

splash guard must slightly touch the

oor.

For the disassembly it is necessary

to proceed inversely with above-men-

tioned operations.

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Loading...

Loading...