18

OVERFLOW DEVICE

In order to avoid serious damages

to the suction motor, the machine is

equipped with a mechanical oat that

intervenes when the recovery tank is

full, closing the air ow of the suction.

When this happens, it is necessary to

empty the recovery tank (see under

paragraph “RECOVERY TANK EMP-

TYING AND CLEANING”).

STOP OF THE MACHINE AFTER

CLEANING OPERATION

IN AUTOMATIC OR MANUAL

WORKING MODE:

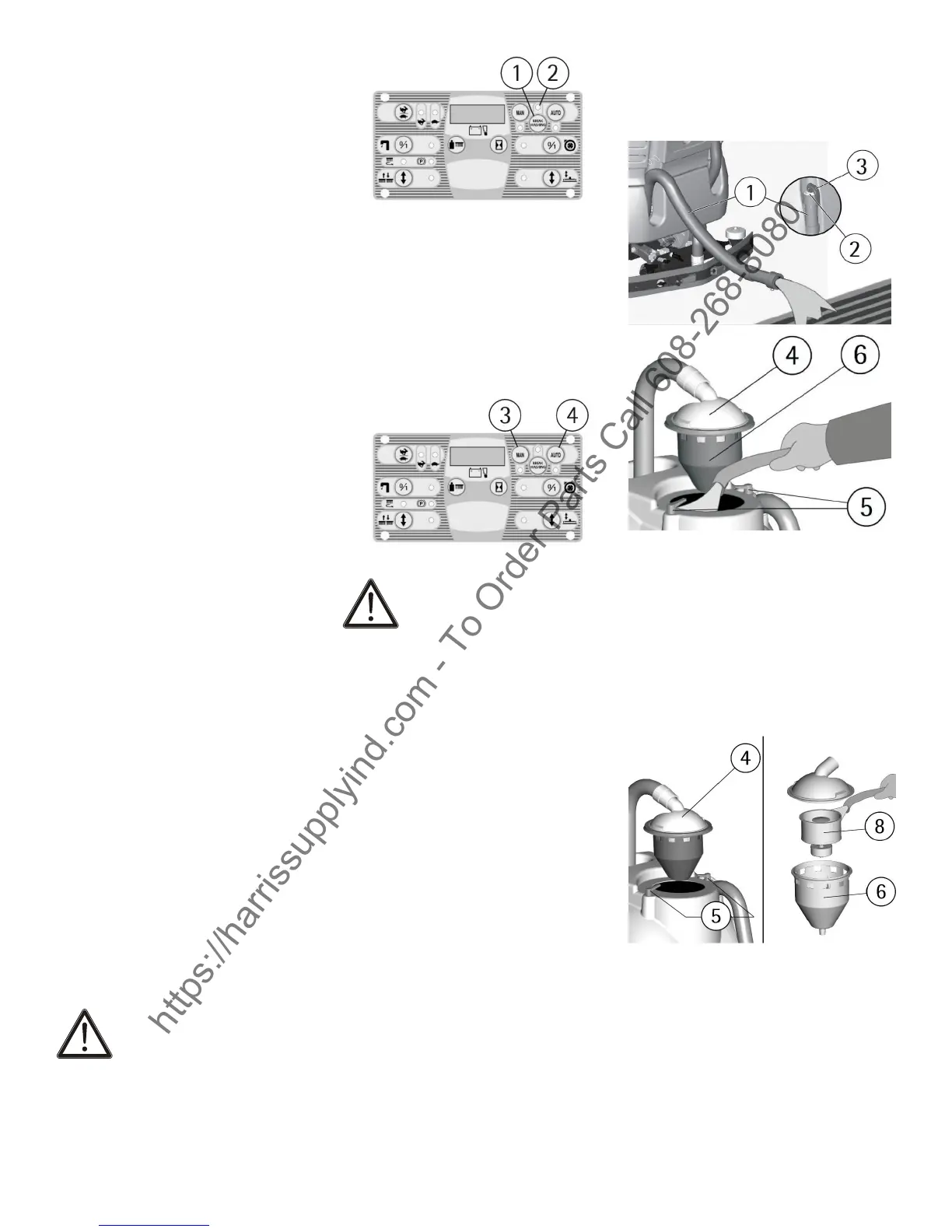

1. A the end of the washing cycle,

pressing the push button (1), the func-

tioning of BREAK WASHING is cho-

sen. When the signal lamp (2) is on,

then the machine then the machine

is in BREAK WASHING mode. In this

way automatically the brushes lift, the

solenoid valve shuts down and it is

possible to nish the drying operation

for a total time of about 15 seconds,

afterwards also the squeegee is lifted

and the suction stops.

NOTE: all these phases are carried

out with the machine operating, so

that the squeegee can dry the clean-

ing area from the “drying phase of the

brushes” and furthermore can dry the

suction hose of its dirty water.

At any time it is possible to interrupt

the procedure BREAK WASHING by

stopping the drive.

2. During the phase of BREAK WASH-

ING, when the accelerator pedal is

released for more than 3 seconds, the

squeegee raises itself and the suction

switches off automatically.

3. After three seconds, the accelerator

can be pressed again, if a machine's

transfer has to be made (you can

make the transfer even if the pedal is

not lifted once the 15 seconds have

passed).

4. Turn the switch key counterclock-

wise to switch off the machine.

ATTENTION:

The mode (BREAK WASHING) is

specic for the transfer at the end of

the cleaning operation.

Re-start the cleaning operation:

A. by pressing the push button (4)

the automatic (AUTO) functioning is

chosen to start working in automatic

mode.

B. by pressing the push button (3) the

manual (MAN) functioning is chosen

to start working in manual mode and

all functions have to be re-established

manually.

DAILY MAINTENANCE

ATTENTION:

All the following maintenance and

cleaning operations that refer to the

following components that are in con-

tact with liquids and therefore:

• Solution and recovery tanks

• Solution and recovery lters

• Squeegee with their rubbers and

hoses

• Brushes

must be carried out using gloves to

protect from contact with dangerous

solutions.

RECOVERY TANK EMPTYING AND

CLEANING

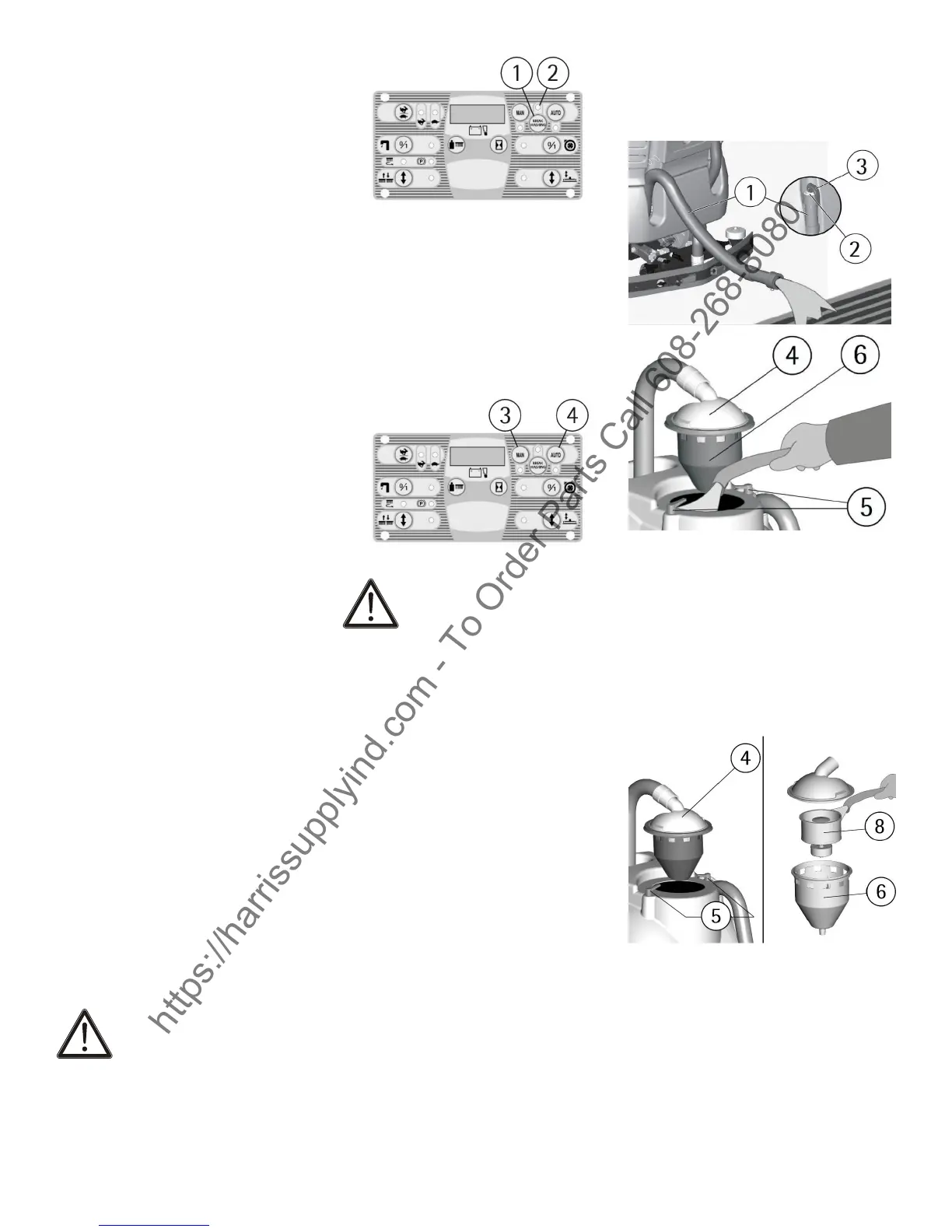

1. Remove the exhaust hose (1) from

the holding bracket.

2. Remove the plug (2) from the

exhaust hose by pulling on the lever

(3) and empty the recovery tank into

appropriate containers, in compliance

with the respective rules.

3. Take off suction cover (4) after rotat-

ing the blocking levers (5).

4. Take off the lter and lter protection

(6).

5. Rinse the inside of the tank with a

water jet.

6. Reassemble all parts.

SUCTION FILTER CLEANING

1. Take off suction cover (4) after rotat-

ing the blocking levers (5).

2. Take off the lter (8) and the lter

protection (6).

3. Clean all parts with a water jet,

especially the inside surfaces and the

lter bottom.

4. Reassemble all parts.

BRUSHES CLEANING

Disassemble the brushes and clean

them with a water jet (for the brushes

disassembly see under paragraph

“BRUSHES DISASSEMBLY”).

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Loading...

Loading...