DriveSystem

Maintenance

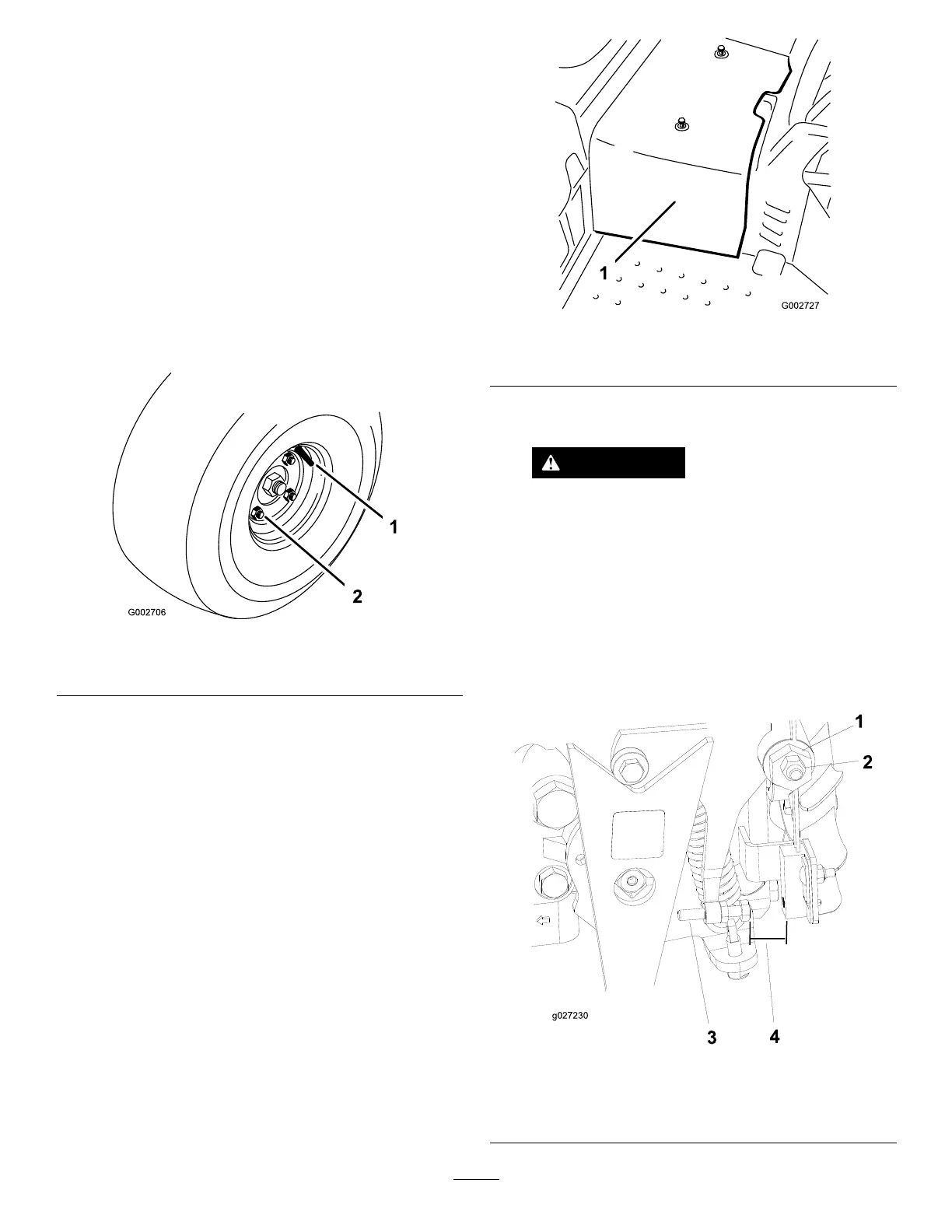

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Checkthetirepressurebeforeoperatingthemachine

(Figure34).Thecorrectairpressureinthefrontand

reartiresisasfollows:

•Treadedtires:70kPa(10psi)

Note:Ifadditionaltractionisrequiredforblade

operation,reducethepressureto55kPa(8psi).

•Smoothtires:55to70kPa(8to10psi)

g002706

Figure34

1.Valvestem2.Lugnut

TorquingtheWheelLug

Nuts

ServiceInterval:Aftertherst8hours

Every100hours

Torquethelugsnutsto95to122N∙m(70to90ft-lb).

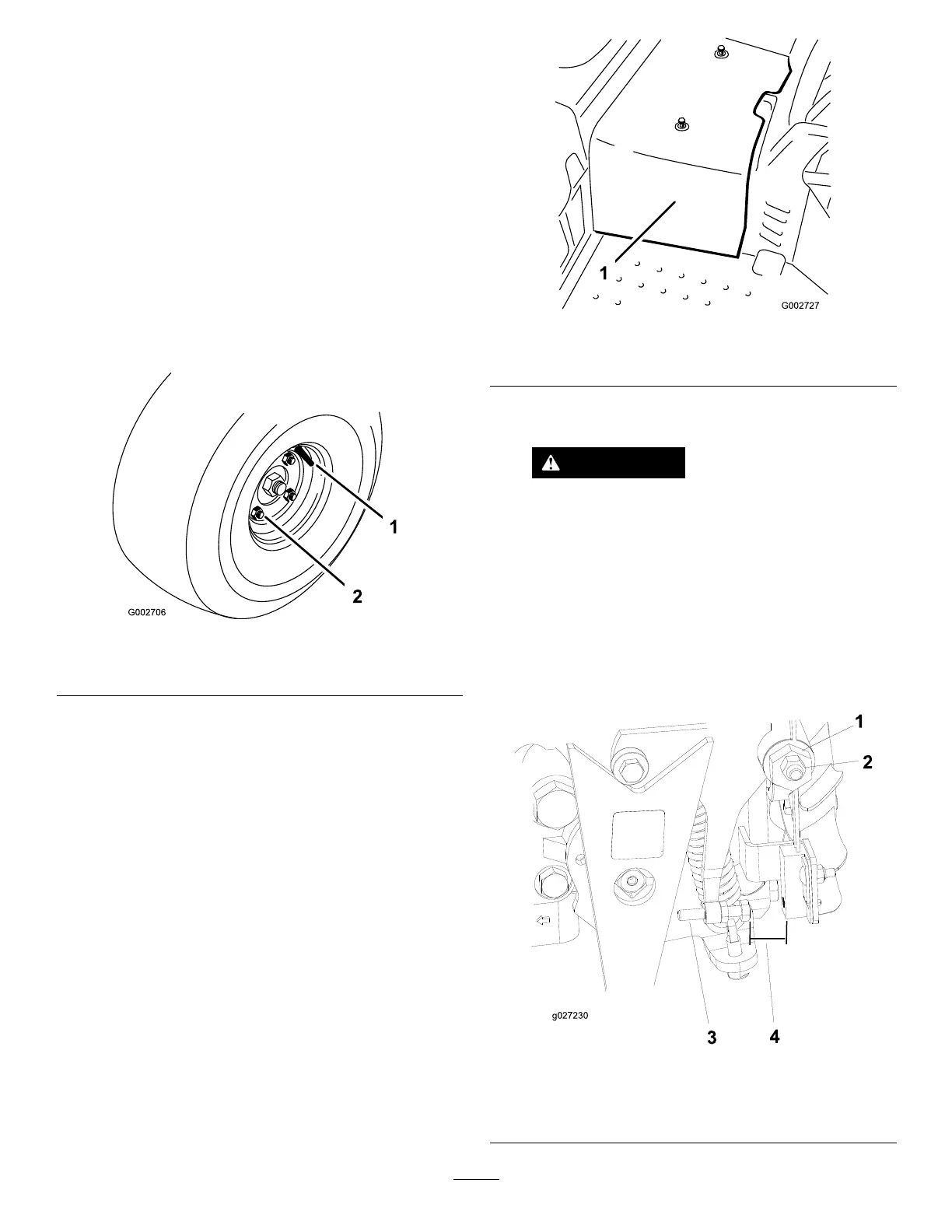

AdjustingtheTraction

DriveforNeutral

Ifthemachinemoveswhenthetractionpedalisinthe

neutralposition,adjustthetractioncam.

1.Parkthemachineonalevelsurface,shutoffthe

engine,engagetheparkingbrake,andremove

thekey.

2.Loosenthe2screwssecuringthecentershroud

tothemachineandremovetheshroud(Figure

35).

g002727

Figure35

1.Centershroud

3.Raisethefrontwheeland1rearwheeloffthe

oorandplacesupportblocksundertheframe.

WARNING

Thefrontwheeland1rearwheelmustbe

raisedofftheground,orelsethemachine

willmoveduringtheadjustment.This

couldcausethemachinetofalland

injuresomeoneunderthemachine.

Makesurethatthemachineisadequately

supported,withthefrontwheeland1

rearwheelraisedofftheground.

4.Loosenthelocknutonthetraction-adjustment

cam(Figure36).

g027230

Figure36

1.Traction-adjustmentcam

3.Screw

2.Locknut

4.Gap

29

Loading...

Loading...