Note:Duetothedeeprecessaroundthespark

plug,blowingoutthecavitywithcompressedair

isusuallythemosteffectivemethodforcleaning.

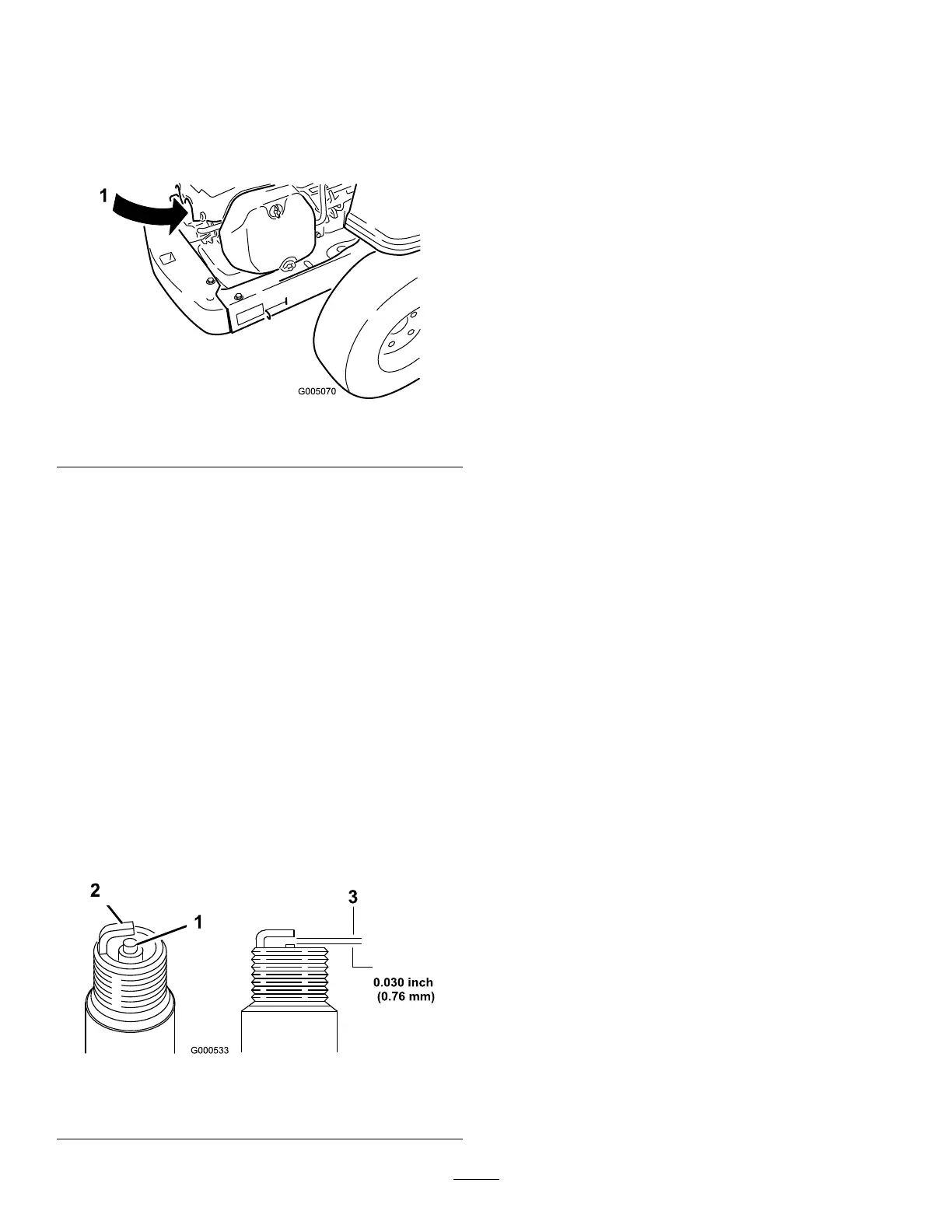

Thesparkplugismostaccessiblewhentheblower

housingisremovedforcleaning.

3.Removethesparkplugandmetalwasher.

Figure28

1.Sparkplugandwirelocation

CheckingtheSparkPlug

ServiceInterval:Every200hours—Checksparkplug

conditionandgap.

Every2years—Checksparkplug

conditionandgap.

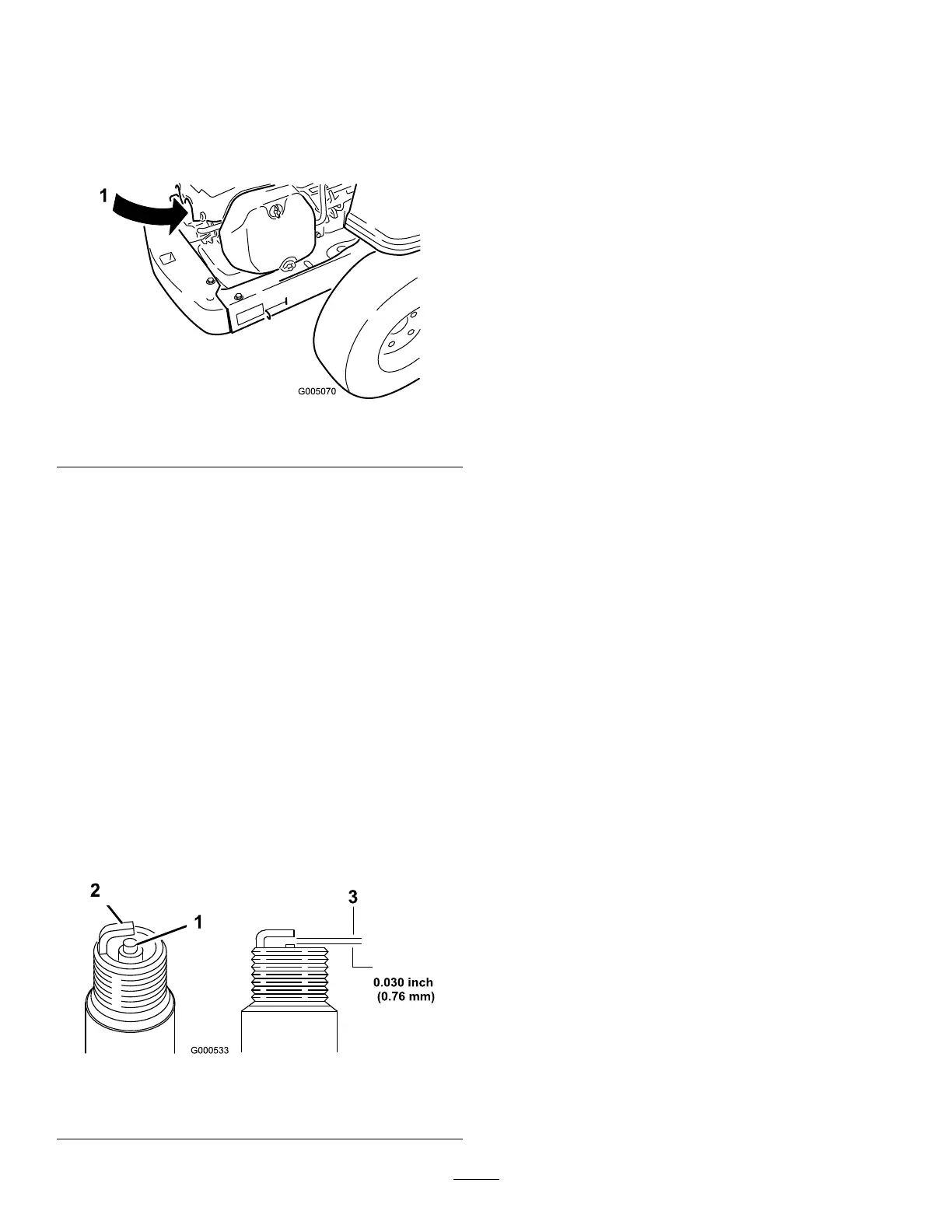

1.Lookatthecenterofthesparkplug(Figure29).

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty.

Important:Nevercleanthesparkplug.Always

replacethesparkplugwhenithasablack

coating,wornelectrodes,anoilylm,orcracks.

2.Checkthegapbetweenthecenterandsideelectrodes

(Figure29).Bendthesideelectrode(Figure29)if

thegapisnotcorrect.

Figure29

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

InstallingtheSparkPlug

ServiceInterval:Every500hours—Replacethespark

plug.

1.Installthesparkplug.Makesurethattheairgapis

setcorrectly.

2.Tightenthesparkplugto30ft-lb(41N-m).

3.Pushthewireontothesparkplug(Figure28).

CleaningtheBlowerHousing

ServiceInterval:Beforeeachuseordaily—Checkair

intakeandcoolingareas(cleanas

necessary).

Every100hours—Cleantheblower

housing(moreoftenunderextremely

dusty,dirtyconditions).

Toensurepropercooling,makesurethegrassscreen,

coolingns,andotherexternalsurfacesoftheengine

arekeptcleanatalltimes.

Removetheblowerhousingandanyothercooling

shrouds.Cleanthecoolingnsandexternalsurfacesas

necessary.Makesurethecoolingshroudsarereinstalled.

Torquetheblowerhousingscrewsto5.5ft-lb(7.5N-m).

Important:Operatingtheenginewithablocked

grassscreen,dirtyorpluggedcoolingns,and/or

coolingshroudsremoved,willcauseenginedamage

duetooverheating.

27

Loading...

Loading...