ElectricalSystem

Maintenance

ChargingtheBattery

RemovingtheBattery

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponentscausing

sparks.Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,do

notallowthebatteryterminalstotouchany

metalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

parkposition,stoptheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removetheleftsideconsoletoaccessthe

battery.RefertheAccessingtheBatteryprocedurein

PremaintenanceProcedures,page23forinstructions.

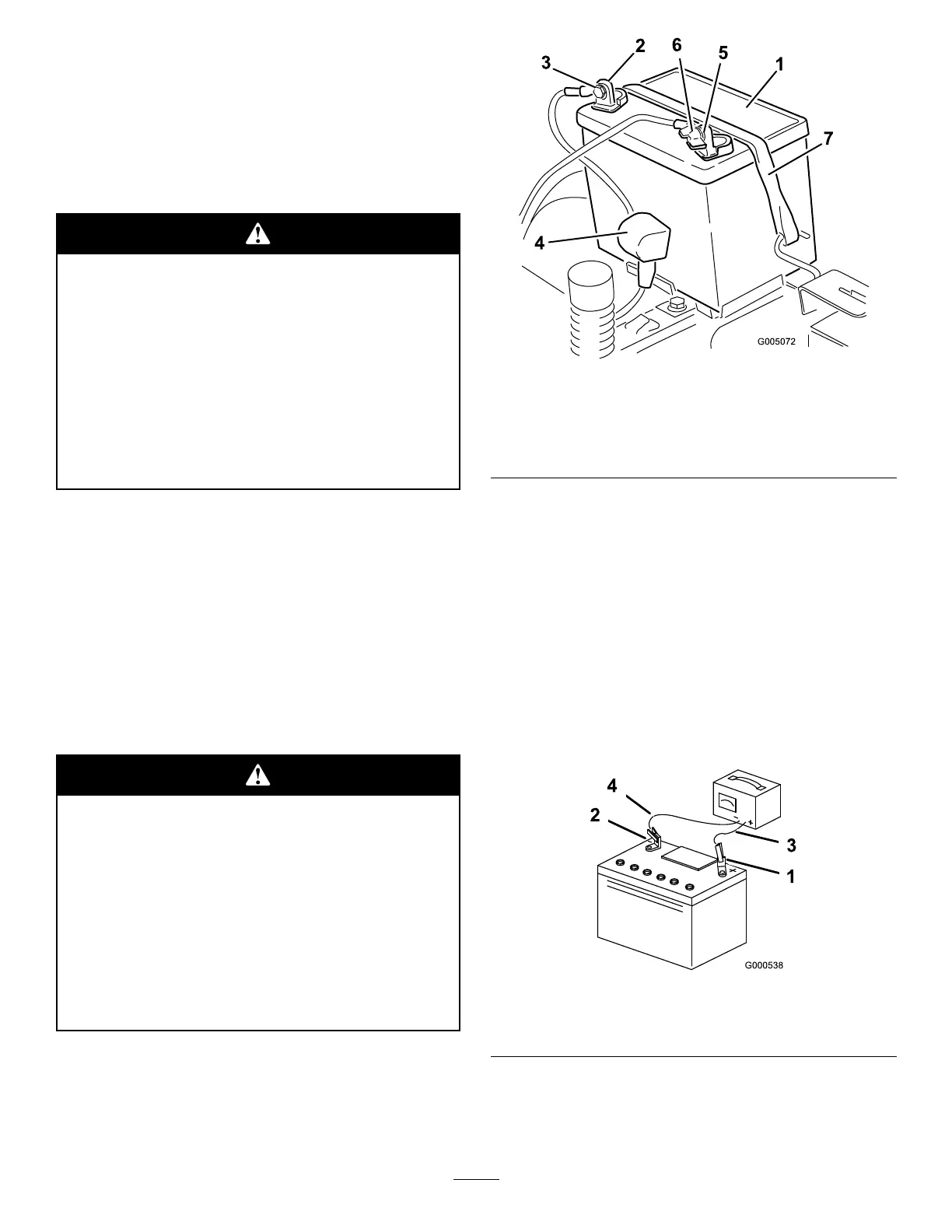

4.Disconnectthenegative(black)groundcablefrom

thebatterypost(Figure31).Retainallfasteners.

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative(black)

cable.

5.Slidetherubbercoverupthepositive(red)cable.

Disconnectthepositive(red)cablefromthebattery

post(Figure31).Retainallfasteners.

6.Removethebatteryhold-down(Figure31)andlift

thebatteryfromthebatterytray.

Figure31

1.Battery5.Negativebatterypost

2.Positivebatterypost6.Wingnut,washer,andbolt

3.Bolt,washer,andnut7.Batteryhold-down

4.Terminalboot

ChargingtheBattery

ServiceInterval:Beforestorage—Chargethebattery

anddisconnectbatterycables.

1.Removethebatteryfromthechassis;referto

RemovingtheBattery.

2.Chargethebatteryforaminimumof1hourat6to

10amps.Donotoverchargethebattery.

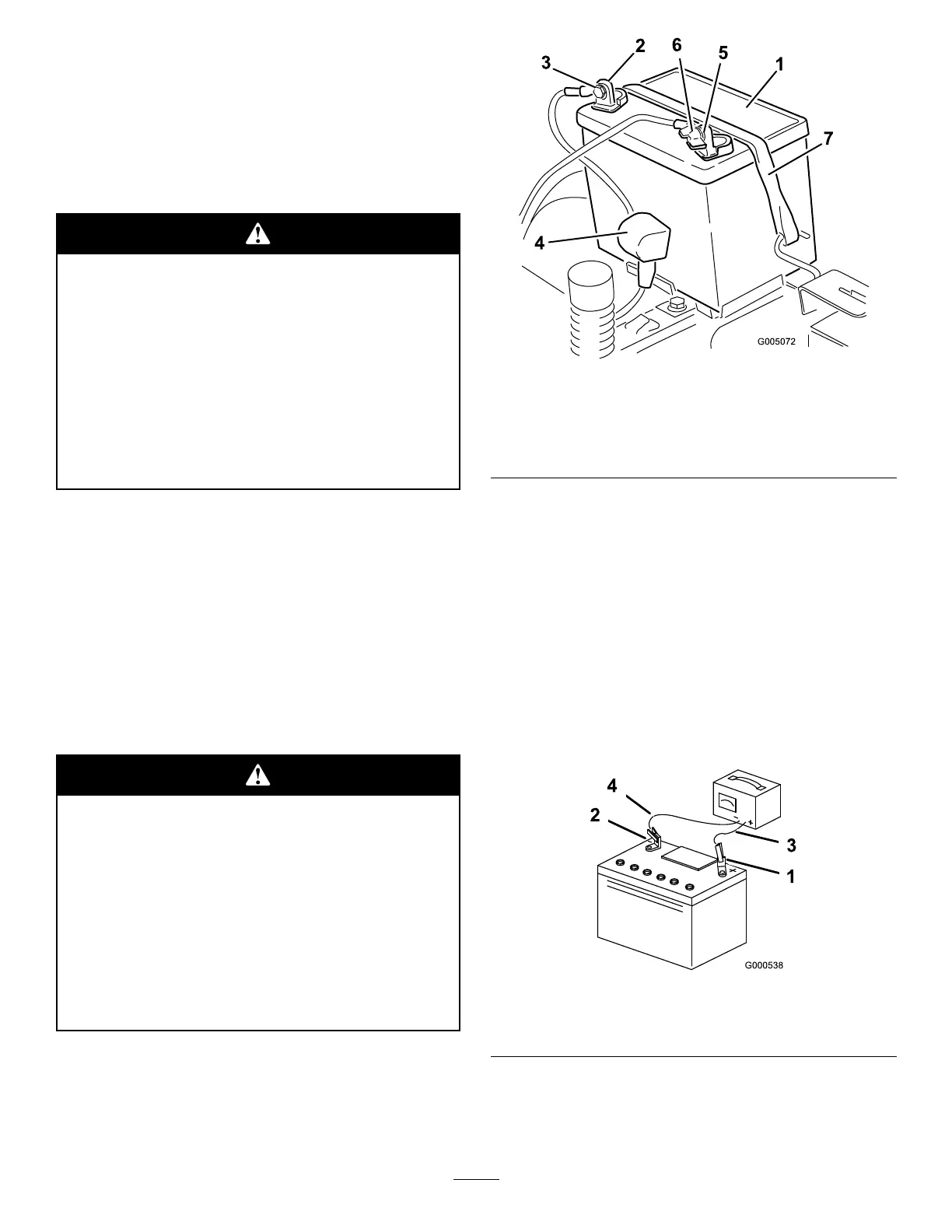

3.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthe

chargerleadsfromthebatteryposts(Figure32).

Figure32

1.Positivebatterypost

3.Red(+)chargerlead

2.Negativebatterypost

4.Black(-)chargerlead

Note:Donotrunthemachinewiththebattery

disconnected,electricaldamagemayoccur.

29

Loading...

Loading...