1

2

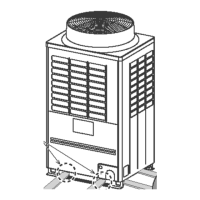

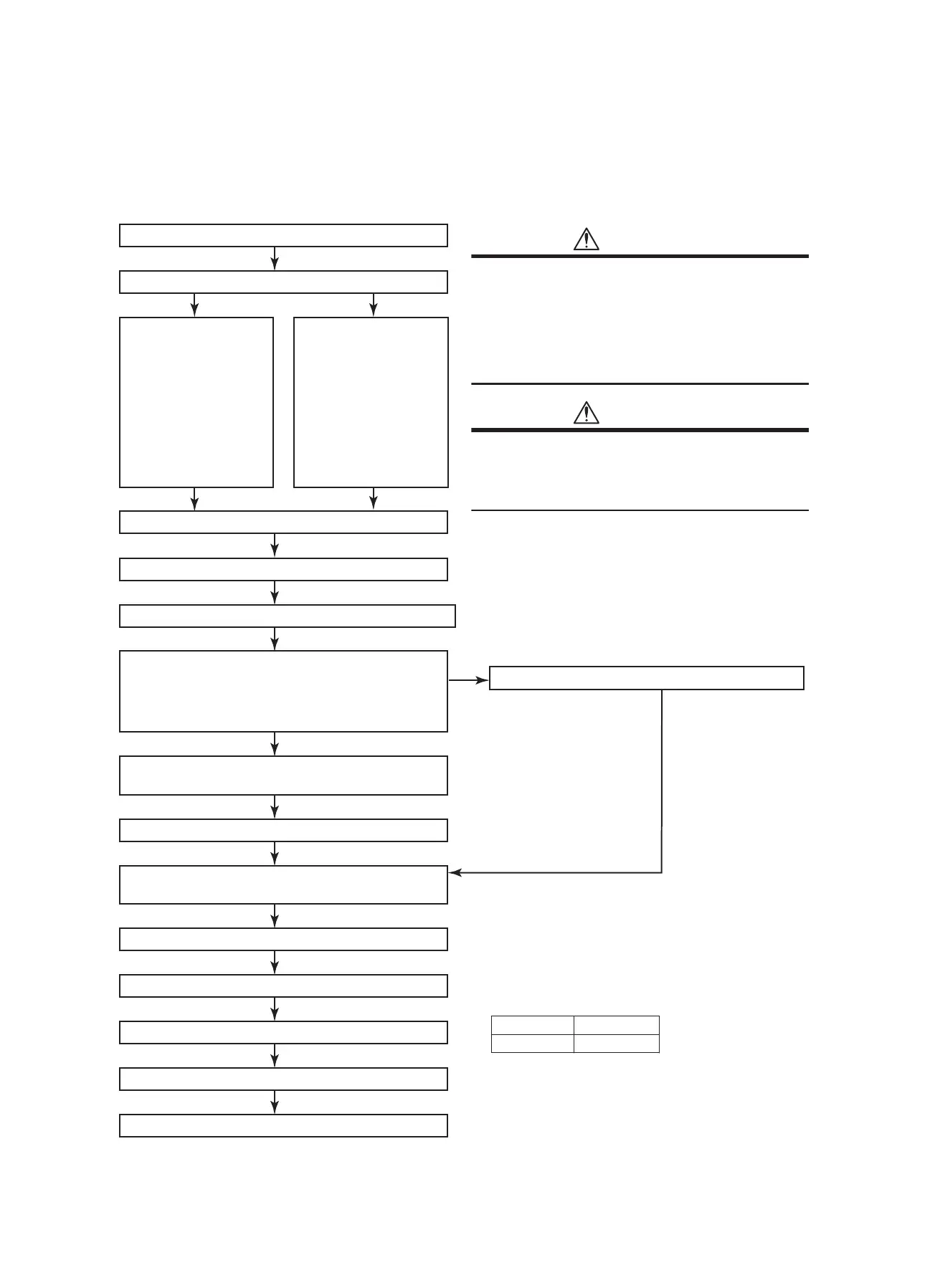

REPLACING COMPRESSORS

12-1. Compressor Replacement Procedure (Outline)

NOYES

NO

START

Is the outdoor unit the only one in the system?

Recover refrigerant

from the failed unit in

accordance with “

11

OU

TD

OOR UNIT

REFRIGERANT

RECOVERY

METHOD”.

Manually open PMV1, 3

and 4 of the failed unit

(by short-circuiting the

pins of CN30 on I/F P.C.

board and turning off the

power switch), and

recover refrigerant using

a refrigerant recovery

device (

*

1).

Turn off the power switch of the failed outdoor unit.

Remove the troubled compressor.

Check the color of the oil in the troubled compressor.

ASTM grade: Is it 4 or above?

(Judge the condition of the oil against color samples,

and decide whether to replace the troubled

compressor only or all compressors.)

YES

Replace both the troubled compressor and the

normal compressor.

Measure the amount of oil in the normal compressor.

Adjust the amount of oil according to the oil quantity

measurement result(s).

Install the new compressor(s) (*2).

Perform a leakage check of the failed outdoor unit.

Perform

vacuum drying in the failed outdoor unit.

Refrigerant charging

END

Measure the amount of oil in the troubled compressor.

Replace the troubled compressor only.

WARNING

In situations such as indoor unit relocation and repairs,

it is not possible to recover all the refrigerant held by the

system in the outdoor units.

It could cause a serious accident, such as blow out or

injury.

Be sure to perform refrigerant recovery using a

refrigerant recovery device.

WARNING

When detaching a pipe by heating with a burner at

brazed joint, take care as any oil left in the piping may

burn in a momentary flash of fire when the brazed filler

metal melts.

*

1 The full-opening of PMV1, 3 and 4 via short-circuiting of the CN30

pins is automatically undone after 2 minutes, causing the valves

to fully close. To maintain fully open state, turn off the power

switch of the outdoor unit within 2 minutes.

*

2 The SMMS-e (6 series) and the SMMS-i (4 series) use different

types of compressors.

Be sure to check the service part code.

This flowchart only shows the standard compressor

replacement procedure. Since the situation can differ

site by site, perform the task in accordance with the

following judgment criteria:

(1) New compressors are charged with 0.502 gal of oil

per unit.

(2) The amount of oil held by an outdoor unit is as

shown below.

(3) When a compressor is dismantled, it usually

contains 0.211 - 0.370 gal oil.

The amount of oil held by an oil separator is usually

0-0.264 gal for MAP0726∗∗

Model MAP-

0726∗

Amount of oil [gal]

1.136

− 228 -

Loading...

Loading...