12-2. Replacement of Compressors

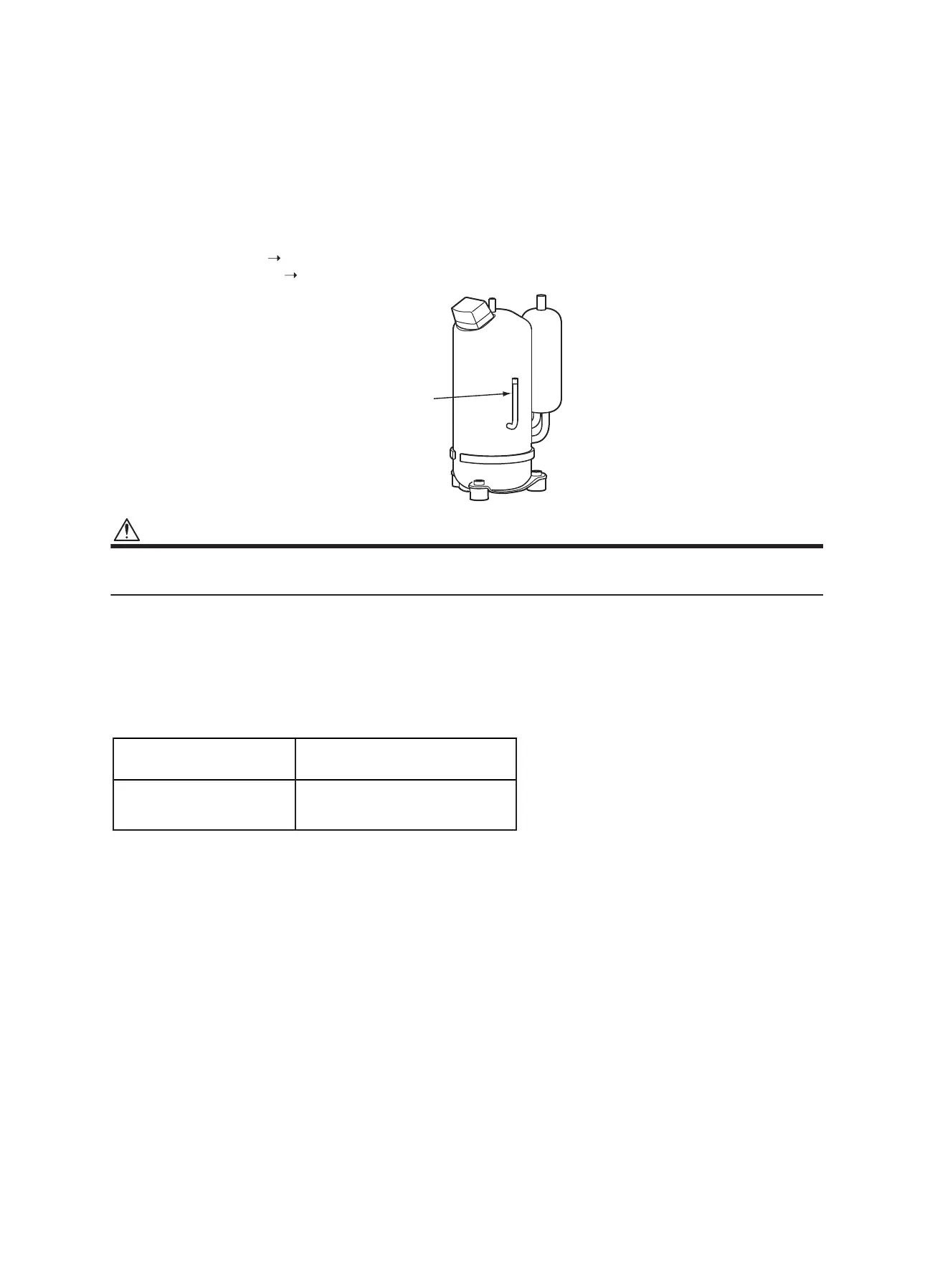

<Checking color of oil in troubled compressor>

• Lay the faulty compressor down, draw a small amount of oil via the oil equalization pipe, and check its color

against color samples.

• Determine the number of compressors to be replaced according to the color checking result.

ASTM grade: Below 4 Replace the troubled compressor only.

ASTM grade: 4 or above Replace both the troubled compressor and the normal compressor(s).

WARNING

When detaching a pipe by heating with a burner at brazed joint, take care as any oil left in the piping may burn in

a momentary flash of fire when the brazing filler metal melts.

<Adjusting amount of oil in new compressor> (0.502 gal at shipment)

• Perform the adjustment on the basis of how much oil the troubled compressor contained, A [gal], by

following the steps below.

1 Amount of oil in faulty compressor A [gal]: 0 ≤ A < 0.264

(1) Adjust the amount of oil in the new compressor to 0.264 gal.

(Lay the new compressor down and draw 0.238 [gal] of oil via the oil-equalization

pipe.)

Notes:

• Do not draw more than 0.238 [gal] of oil as it may cause damage to the compressor.

• If the troubled compressor contained 0.132 [gal] or less, there may have been a problem with the oil

equalization circuit, etc. Perform checks in accordance with “12-3. Check Procedure to Search Cause of

Compressor Oil Shortage”.

Compressor

Oil equalization

pipe

(lbs)

Compressor model

DA421A3TB-20M1

48.2

※Please check the type name of the compressor as it was dismantled.

D:Weight

[When replacing troubled compressor only]

<Measuring amount of oil in troubled compressor>

Amount of oil in troubled compressor: A [gal] = (Weight of compressor as it was dismantled

(lbs) - D) x 0.1249 (Specific volume of oil: 0.1249 [gal/lbs])

(not include oil)

− 230 −