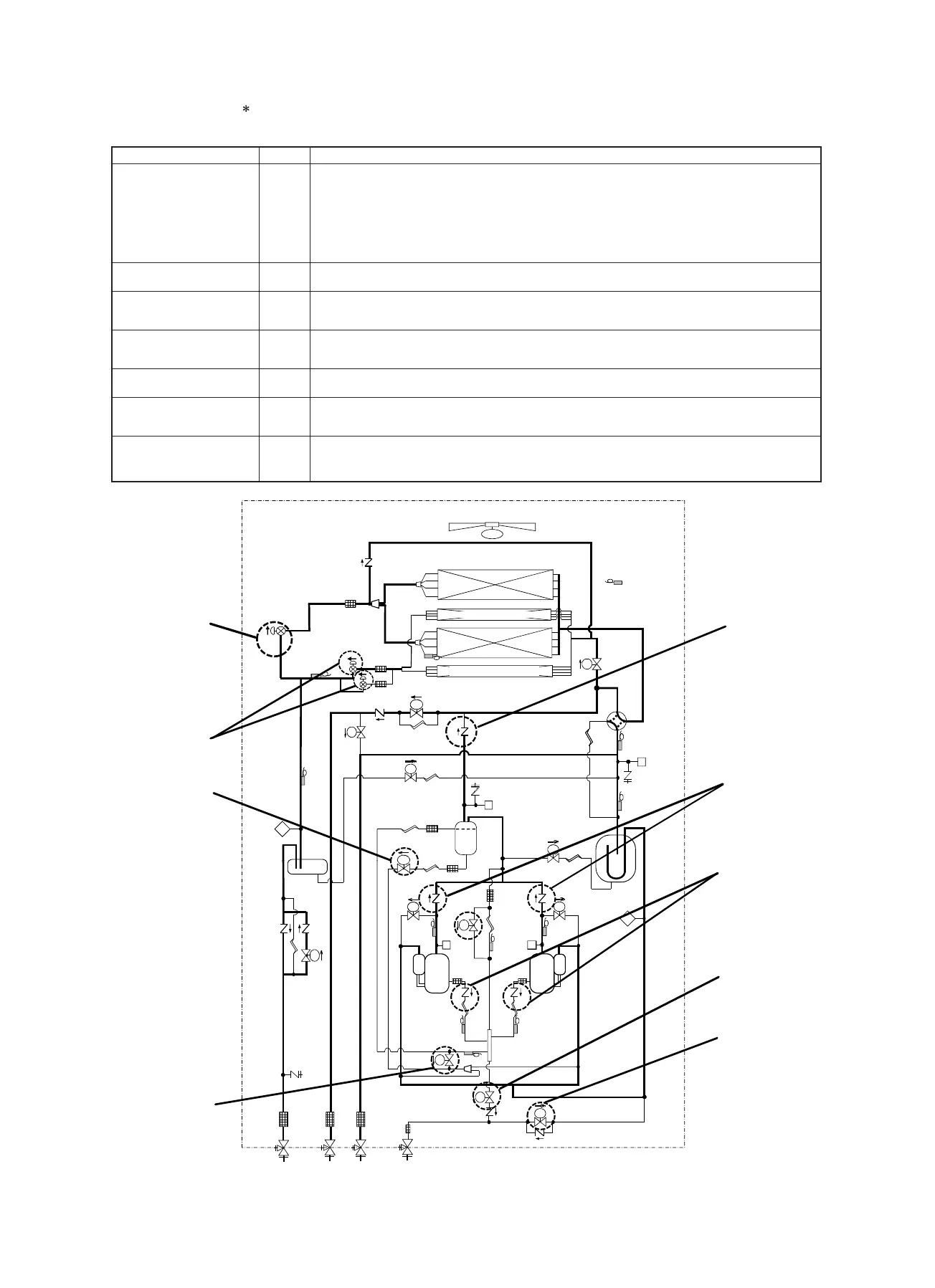

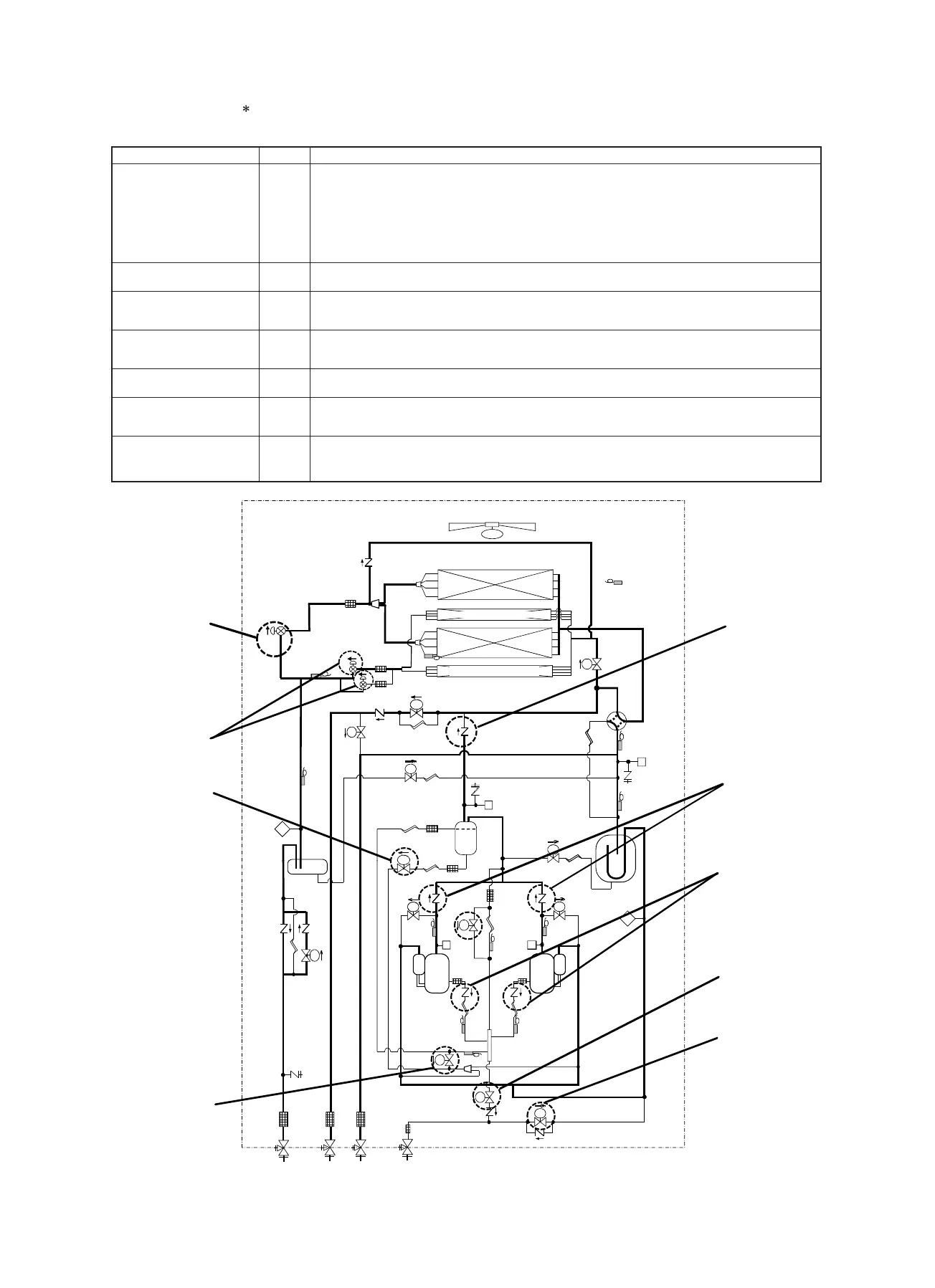

<MMY-MAP0726 >

Check items and procedures to follow when checking oil circuit with compressor(s) disconnected

− 235 −

Check item Location Procedure

Leakage of outdoor PMV

Leakage of check valve in

discharge pipe convergent

section

A,B

C

1) Pressure nitrogen from check joint of the liquid pipe under condition that PMV1, 3 and 4 are fully closed,

confirm the pressure using high-pressure check joint.

If pressure of the high-pressure check joint rises, leakage from any of PMV1, 3, 4 (A, B) and discharge check

valve (C) is considered. Therefore replace all PMV1, 3, 4 (A, B) and discharge check valve (C).

2) If pressure did not rise, open PMV1 fully and then confirm pressure of the high-pressure check joint.

When pressure was up, open fully PMV4 only and confirm pressure of the high-pressure check joint again.

3) When pressure was up, there is leakage from discharge check valve (C). Therefore replace them.

If pressure did not rise, there is leakage from discharge check valve. Therefore replace them.

Leakage of check valve in

discharge pipe

E

4) With pressure applied to the check joint of with nitrogen, if gas escapes from the discharge pipe section of the

disconnected compressor, there is a leak from the check valve of discharge pipe (E). Replace the part.

Leakage of check valve in

oil equalization circuit

F

5) With pressure applied to the check joint of with nitrogen, if gas escapes from the oil equalization pipe section

of the disconnected compressor, there is a leak from the oil equalization pipe check valve (F).

Replace the part.

Leakage of SV3A valve G

6) With pressure applied to the check joint of with nitrogen, manually open the SV3B valve. If gas escapes from

the suction pipe section of the disconnected compressor, there is a leak from the SV3A valve.

Replace the part.

Clogging of SV3E valve

Clogging of oil-return distributor

I

8) With pressure applied to the check joint of with nitrogen, manually open the SV3E valve. If gas does not

escape from the suction pipe section of the disconnected compressor, the SV3E valve or oil-return distributor

is clogged. Replace the part.

Clogging of SV3D valve

Clogging of oil-return capillary

Clogging of oil-return distributor

J

9) With pressure applied to the check joint of with nitrogen, manually open the SV3D valve. If gas does not

escape from the suction pipe section of the disconnected compressor, the SV3D valve, oil-return capillary or

oil-return distributor is clogged. Replace the part.

Leakage of SV3B valve H

7) Then manually open the SV3A valve. If gas escapes from the suction pipe section of the disconnected

compressor, there is a leak from the SV3B valve. Replace the part.

FM

Propeller

Fan

(Right side)

Main heat exchanger

Fusible plug

FPFP

PMV4

GEARED PMV3

SV

SV15

(TO)

(TE2)

(TE1)

(TL1)

(SV5)

SV

(SV6)

Check joint

(high pressue)

High pressue sensor

4-way

Valve

(TS1)

(TS2)

Check joint

(low pressue)

Low pressue sensor

Accumlator

SV

Oil separator

Centrifugal

(SV3D)

type

(SV2)

SV

SV

Sub-heat exchanger (Right side)

(SV11)

(Left side)

Main heat exchanger

GEARED PMV1

SV

SV

Liquid tank

(SV14)

Check joint

(Liquid)

(SV41)

SV

(SV42)

(SV3C)

(TD1)

(TD2)

(TK4)

High

pressure

SW

High

pressure

SW

Comp 1

(INV)

C

C

om

om

p

p

2

2

(TK1)

(TK2)

(SV3A)

(SV3E)

(TK5)

Oil

header

SV

B.P.

(SV3B)

SV

SV

(I(INVNV))

SV

SV

SV

SV

SV

Liquid side

Service valve

Discharge-gas

side

Service valve

Balance pipe

Service valve

Suction-gas

side

Service valve

Fusible plug

FP

A

B

J

I

C

E

F

G

H

Sub-heat exchanger (Left side)

Loading...

Loading...