CGWF-SVX01A-EN 21

Installation Mechanical

Alternate Moving Methods

If it is not possible to rig from the previous method shown inFigure 4 and Figure 5,

the unit my also be moved by jacking each end high enough to move an equipment

dolly under each end of the unit frame. Once securely mounted on the dollies, the

unit may be rolled into position. Jacks should be positioned to lift under the lifting

angles installed on the unit by the contractor.

Access Restrictions

All CGWF/ CCAF units will pass through a standard 36-inch doorway. Typical

dimensions are shown in Figure 7 - Figure 11.

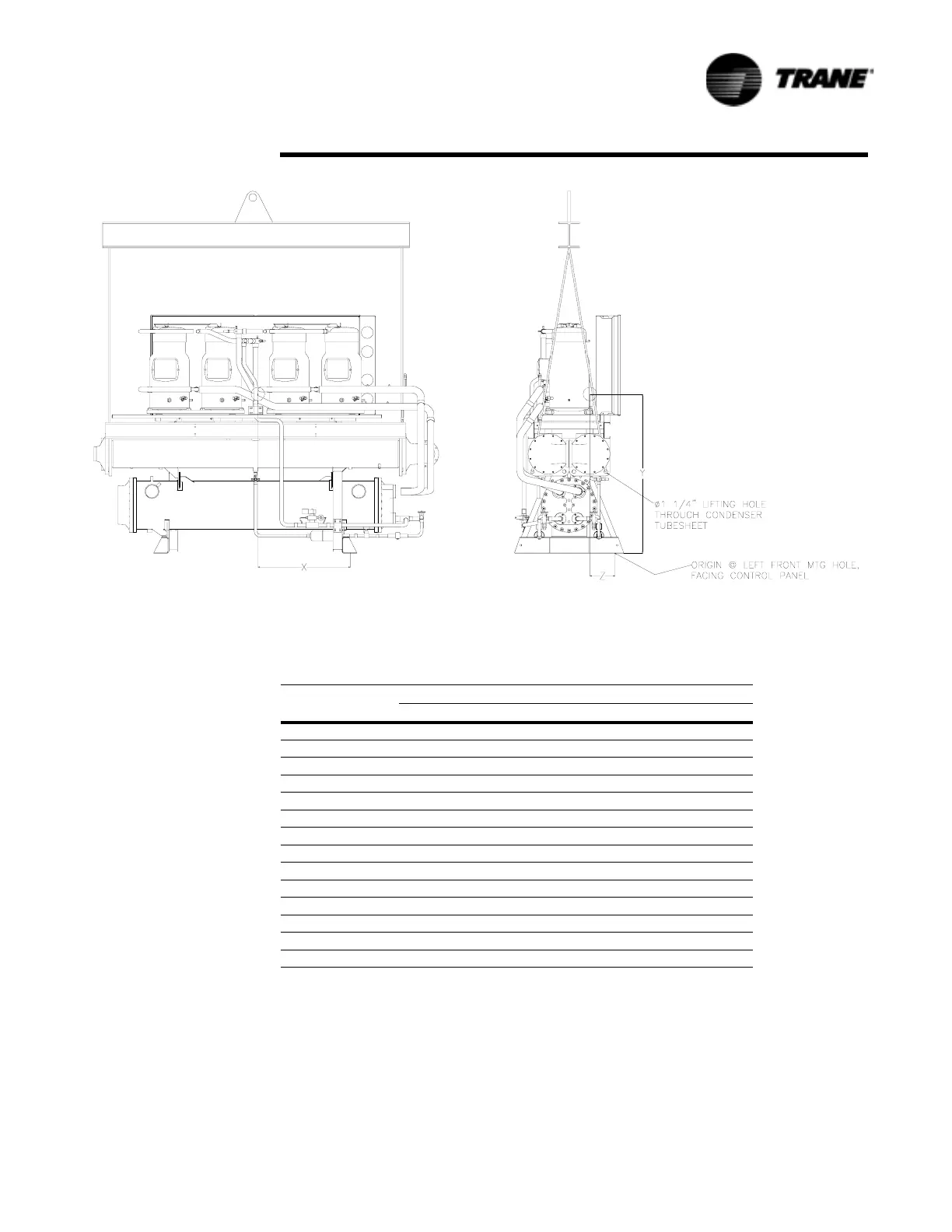

Figure 5 Typical Rigging Setup For CGWF 60 Ton Units.

1. Use clevis pins for attachment of chains to lifting

holes, lifting chains (cables) may be adjusted for

level lifting.

2. Do not Forklift Unit.

3. All units are heavier on the control panel side. Use

Table 5 to adjust rigging accordingly.

4. Minimum beam length 6ft.

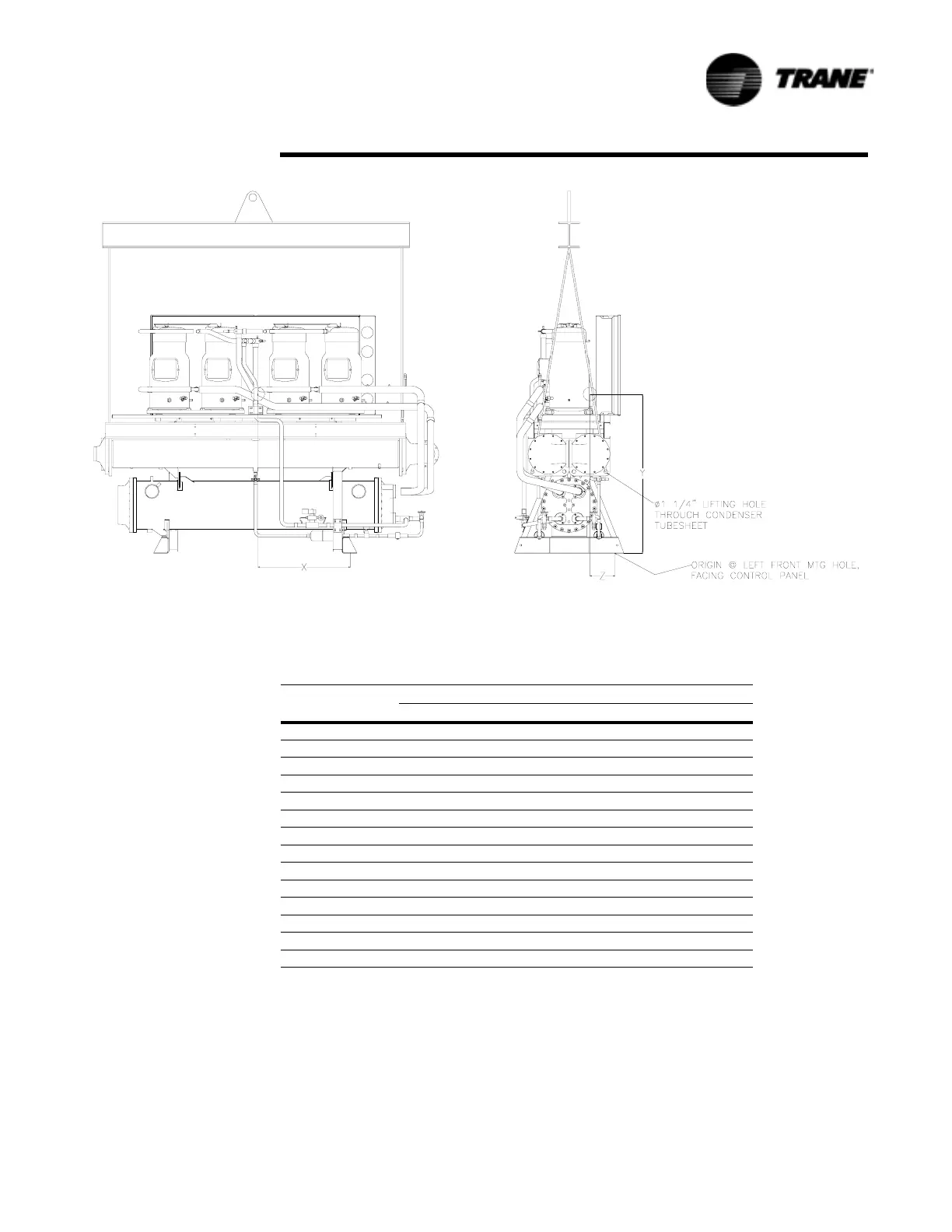

Table 5 Center of Gravity Dimensions

Unit Size Location of Center of Gravity (in)

XYZ

CGWF

20 18 24 9

25 18 25 9

30 18 26 9

40 23 26 8

50 23 27 9

60 28 31 13

CCAF

20 28 31 8

25 28 30 8

30 28 28 8

40 33 29 8

50 33 27 8

60 33 26 8

Loading...

Loading...