RLC-SVX023A

42

4 UNT-PRC002-GB

Technical Data

FWD 08 12 20 30 45

Power supply (V/Ph/Hz) 230/1/50

Capacities

Cooling capacity on water (1) (kW) 5,2 8,3 15 18,8 30,1

Heating capacity on water (2) (kW) 6,3 11,9 18,9 20,9 38,2

Fan motor (type) 2 x direct drive centrifugal

Fan power input (3) (kW) 0,23 0,46 0,65 1,04 1,51

Current amps (3) (A) 1,1 2,2 3,1 4,7 5,5

Start-up amps (A) 3,2 5,5 9,3 14,1 16,5

Air flow

minimum (m

3

/h) 490 980 1400 1800 2700

nominal (m

3

/h) 820 1650 2300 3000 4500

maximum (m

3

/h) 980 1970 2600 3600 5400

Main coil

Water entering/leaving connections (type) ISO R7 rotating female

(Dia) 3/4" 3/4" 1 1/2" 1 1/2" 1 1/2"

Electric heater (accessory for blower only)

Electric power supply (V/Ph/Hz) 230/1/50 230/1/50 or 400/3/50 400/3/50 400/3/50 400/3/50

Heating capacity (kW) 2/4 8 10 12 12

Hot water coil (accessory for blower only)

Heating capacity (4) (kW) 6,3 12 17,4 22,4 34,5

G2 filter (filter box accessory)

Quantity 2 2 2 2 2

Dimensions ( LxWxth) (mm) 386x221x8 486x271x8 586x321x8 586*421*8 586*621*8

G4 filter (filter box accessory)

Quantity - 2 2 2 2

Dimensions ( LxWxth) (mm) - 486x264x48 586x314x48 586*414*48 586*614*48

Condensate pump (accessory) (type) Centrifugal

Water flow - lift height (l/h - mm) 24 - 500

Not available for FWD30 and FWD45

Sound level (L/M/H speed)

Sound pressure level (5) (dB(A)) 36/40/43 38/41/44 46/50/53 47/52/57 47/52/58

Sound power level (5) (dB(A)) 46/50/53 48/51/54 56/60/63 57/62/67 57/62/68

Unit dimensions

Width x Depth (mm) 890 x 600 1090 x 710 1290 x 820 1290 x 970 1290 x 1090

Height (mm) 250 300 350 450 650

Shipped unit dimensions

Width x Depth (mm) 933 x 644 1133 x 754 1333 x 864 1333 x 1008 1333*1133

Height (mm) 260 310 360 460 660

Weight (kg) 32 46 61 76 118

Colour galvanised steel

Recommended fuse size

Unit alone (aM/gI) (A) 8/16 8/16 8/16 8/25 8/25

Unit with electric heater (gI) (A) 16 (2kW),25 (4kW) 40 (230V),3*16 (400V) 3*20 3*25 3*25

(1) Conditions: Water entering/leaving temperature: 7/12 °C, Air inlet temperature 27/19°C DB/WB - Nominal air flow

(2) Conditions: Water entering/leaving temperature: 50/45 °C, Air inlet temperature 20°C DB - Nominal air flow

(3) At high speed with nominal air flow.

(4) Water entering/leaving temperature 90/70 °C, air inlet temperature 20 °C DB, Nominal air flow.

(5) A rectangular glass wool duct 1m50 long is placed on the blower.The measurement is taken in the room containing the blower unit.

Heat exchanger operating limits:

FWD:

*water temperature: max 100° C

*absolute service pressure: min 1 bar/max 11 bars

Accessories - Hot water coil:

*water temperature: min. +2° C/max. 100° C

*absolute service pressure: min 1 bar/max 11 bars

Maintenance Procedures

Table 6 - POE Oil Properties

Description Acceptable Levels

Moisture content less than 300 ppm

Acid Level

(mg KOH/g)

less than 0.5 TAN

Running the chiller at minimum load is the best for the quickest return of oil to the separator and sump. The machine

still needs to sit for approximately 30 minutes before the level is taken. At minimum load, the discharge superheat

should be highest. The more heat in the oil as it lays in the sump, the more refrigerant will boil off in the sump and

leave more concentrated oil. The oil level in the oil sump can be measured to give an indication of the system oil

charge. Follow the procedures below to measure the level.

1. Run the unit fully unloaded for approximately 20 minutes.

2. Cycle the compressor off line.

Oil Level Check

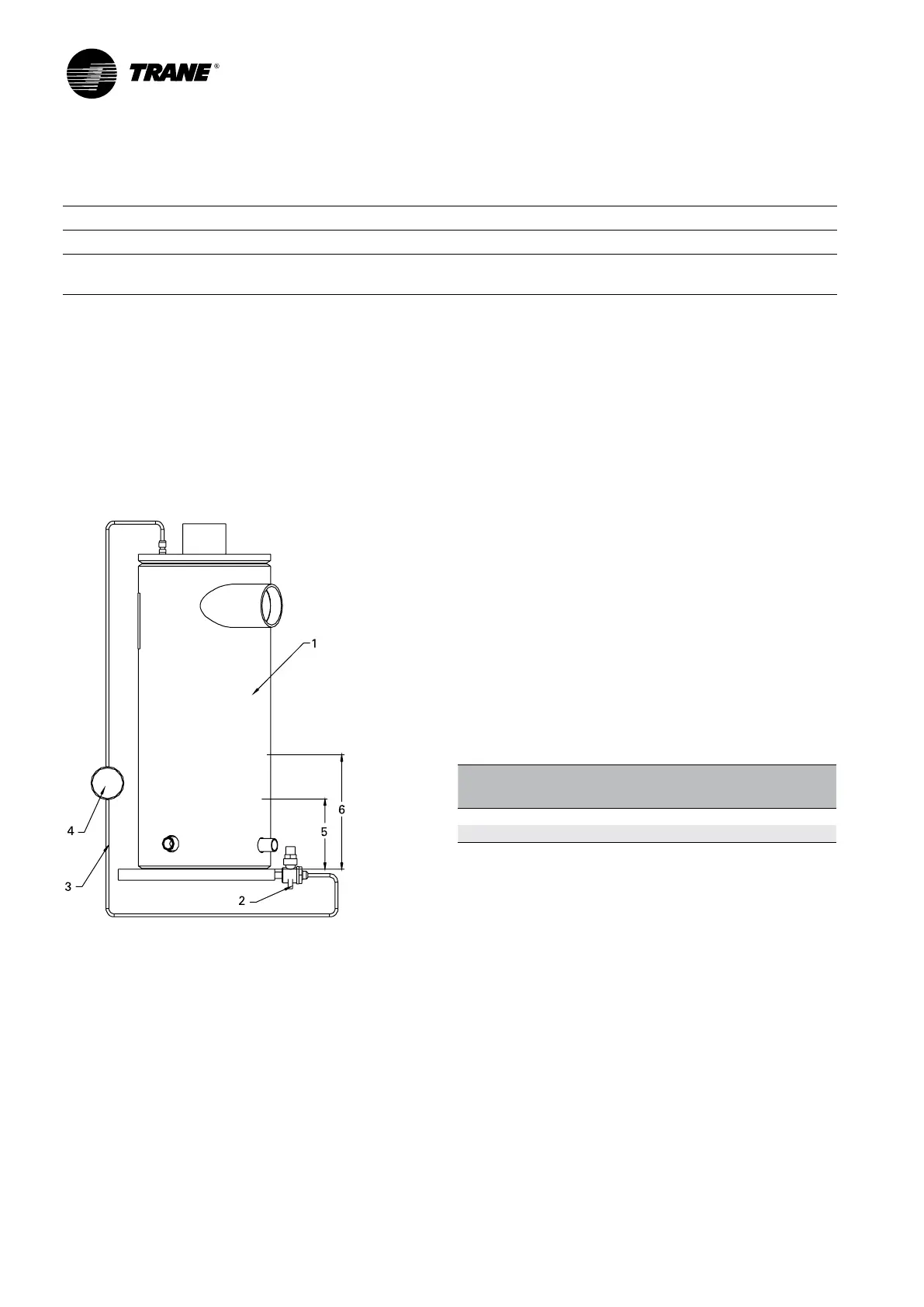

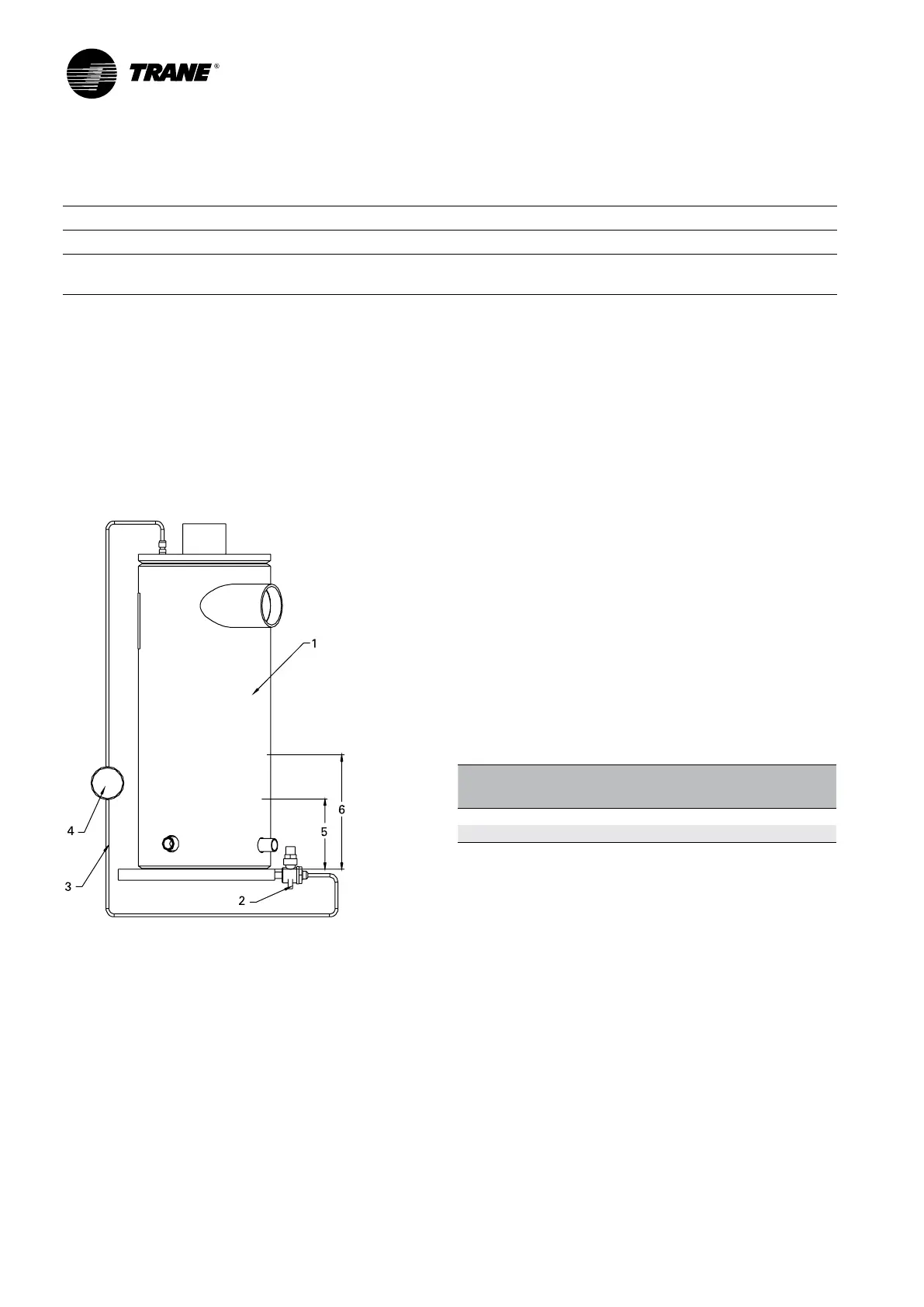

Figure 9 – Determining oil level in the oil separator

1 = Oil separator

2 = Valve

3 = 1/4” refrigeration hose

4 = Sight glass

5 = Minimum oil level

6 = Maximum oil level

How to measure the oil level:

1. Use the oil drain valve (bottom side) and the

service valve on the oil separator (top side). This

measurement can be made, when the circuit is not

running. Note: the bottom plate of the oil separator is

approximately 25mm thick.

2. The initial oil charge should be approximately at the

level in of the above chart. This is the approximate

oil level if all the oil is in the oil lines, filter, and oil

sump, and the unit is in vacuum so that there is no

refrigerant dissolved in the oil.

After the unit has run for a while, the oil level in the

sump can vary greatly. However, if the unit has run

‘normal’ conditions for a long time, the minimum and

maximum oil levels should correspond to values shown

in below table. However excessive oil in the system will

deteriorate the evaporator approach temperature.

Oil

separator

size

Compressors type

Min. oil

level (mm)

Max. oil

level (mm)

8” “M” type 50 mm 180 mm

10” “N” type 50 mm 140 mm

The field charging procedure depends on the

circumstances that resulted in the need for oil charge.

1. Some services procedures may result in loss of

small quantities of oil that must be replaced (oil

analysis, compressor filter replacement, re-tubing the

evaporator, and so forth).

2. Additionally, some maintenance procedures

may result in virtually all the oil being removed

(compressor motor burn or total removal of the charge

to trouble shoot a unit).

3. Finally, leaks may result in a loss of oil that must be

replaced.

Oil charging data.

The oil quantity is written on the nameplate of the unit.

Loading...

Loading...