WSHP-SVX01Y-EN

57

Figure 61. Fan motor and sheave adjustment

1. Belt

2. Adjustment bolt and plate

3. Sheave

Vertical 0.5–5 tons - Units with Deluxe

24V or Tracer®® ZN524 controls

For vertical sizes GEVG 006-060, the ECM is

programmed for constant torque and delivers airflow

similar to a PSC motor while operating at a higher

efficiency.

Figure 62. ECM control box

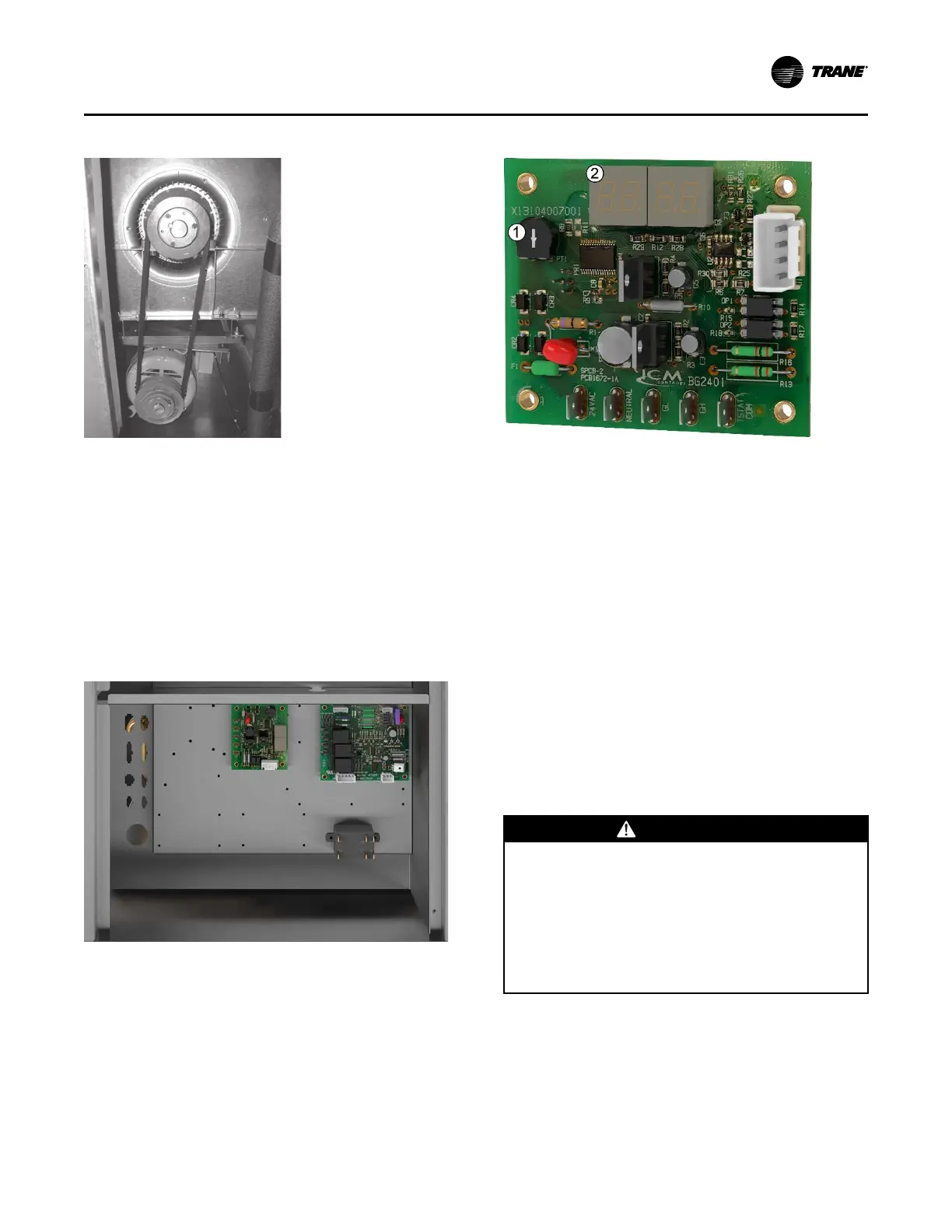

Figure 63. ECM control board

1. Potentiometer will be used to adjust the PWM

output

2. Seven segment display

Using a screwdriver, the potentiometer will be used to

adjust the PWM output from 20% to 100% PWM.

Increasing the PWM will increase the motor speed.

When setting the airflow for air balancing, the high-

speed terminal (GH) must have 24 Vac signal. This will

ensure that the PWM output will be adjusted for the full

load airflow.

The display will show the commanded motor speed

percentage. If running on low speed (GL), the low-

speed value will be displayed. If running in GH the

high-speed value will be displayed. If both GH and GL

input signals are present, the PWM output value will be

the GH value.

Waterside Economizer

Installation

WWAARRNNIINNGG

HHaazzaarrddoouuss VVoollttaaggee!!

FFaaiilluurree ttoo ddiissccoonnnneecctt ppoowweerr bbeeffoorree sseerrvviicciinngg ccoouulldd

rreessuulltt iinn ddeeaatthh oorr sseerriioouuss iinnjjuurryy..

DDiissccoonnnneecctt aallll eelleeccttrriicc ppoowweerr,, iinncclluuddiinngg rreemmoottee

ddiissccoonnnneeccttss bbeeffoorree sseerrvviicciinngg.. FFoollllooww pprrooppeerr

lloocckkoouutt//ttaaggoouutt pprroocceedduurreess ttoo eennssuurree tthhee ppoowweerr

ccaann nnoott bbee iinnaaddvveerrtteennttllyy eenneerrggiizzeedd.. VVeerriiffyy tthhaatt nnoo

ppoowweerr iiss pprreesseenntt wwiitthh aa vvoollttmmeetteerr..

IInnssttaallllaattiioonn

Loading...

Loading...