RLC-SVX02G-E4

36

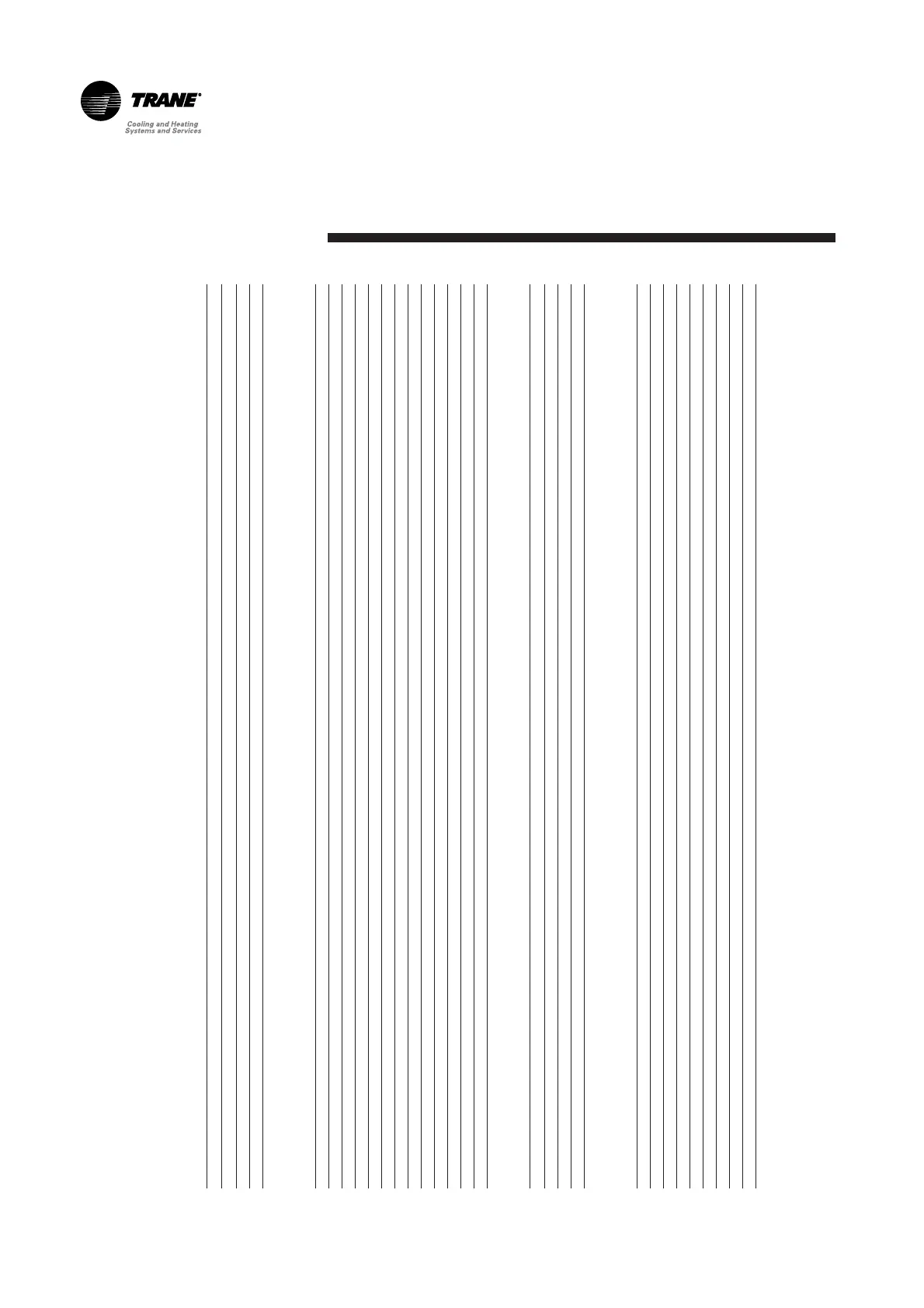

Installation - Mechanical

Chart 1 - Recommended Low Evaporator Refrigerant Cutout and % of Glycol for RTAC Chillers

2345678234567

41.2––33344–11223

2 -0.8 – – 8 9 9 10 – – 7 8 8 9 –

0 -2.8 – 13 13 14 15 16 – – 12 13 14 15 –

-2 -4.8 – 17 18 19 21 – – – 17 18 20 – –

-4 -6.8 – 21 22 25 – – – – 21 23 – – –

-5 -7.8 – 23 24 – – – – – 23 27 – – –

-6 -8.8 – 25 28 – – – – – 25 – – – –

-7 -9.8 – 27 – – – – – – 28 – – – –

-8 -10.8 – 29 – – – – – – – – – – –

-9 -11.8 – 32 – – – – – 29 – – – – –

-10 -12.8 – – – – – – – 31 – – – – –

-11 -13.8 – – – – – – – 33 – – – – –

-12 -14.8 34 – – – – – – – – – – – –

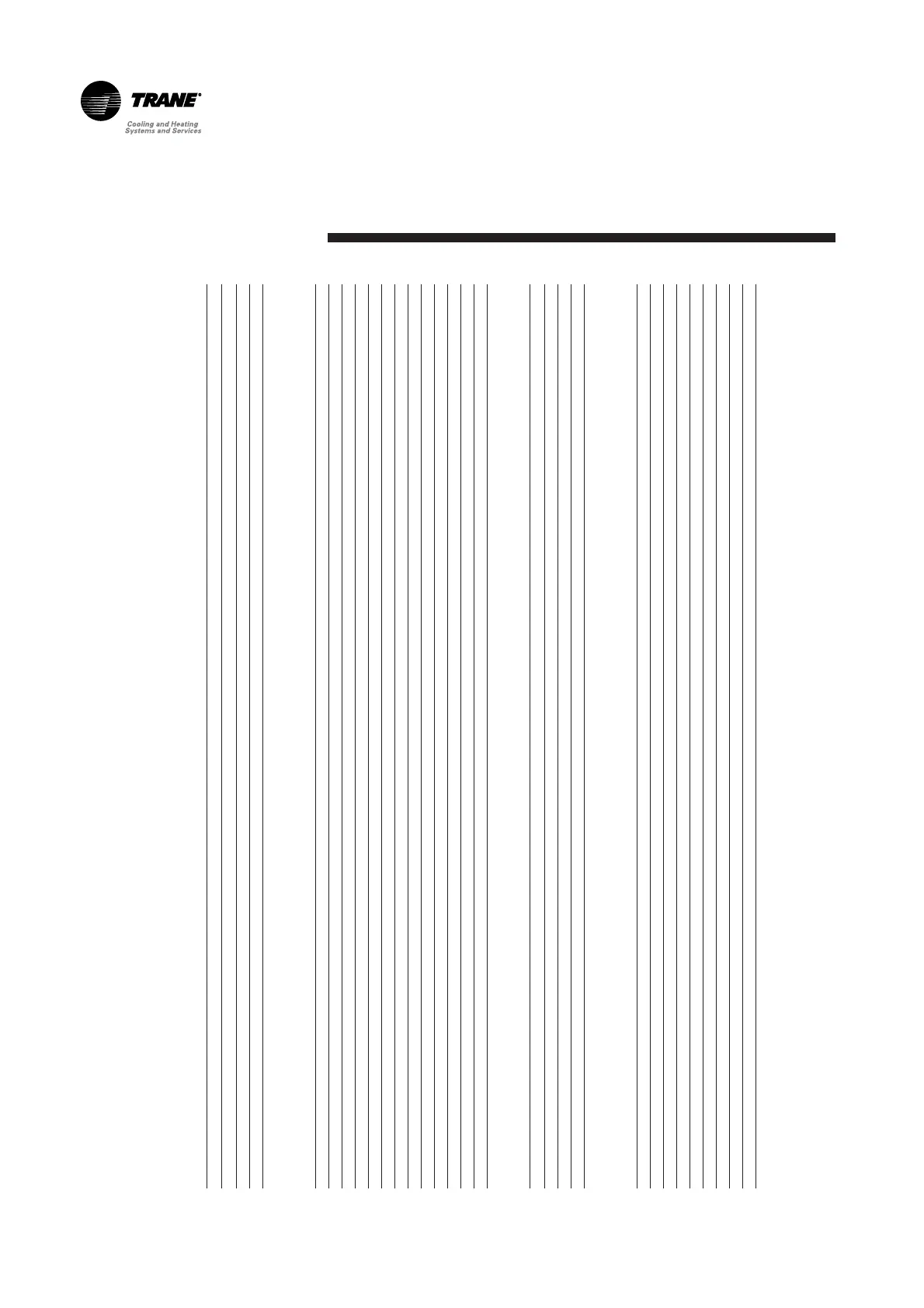

Chart 2 - Recommended Low Evaporator Refrigerant Cutout and % of Glycol for RTAC Chillers

2345 678234567

41.2––34456–22345

2 -0.8 – – 10 11 13 16 – – 9 10 11 14 –

0 -2.8 – 15 16 19 – – – – 15 17 – – –

-2 -4.8 – 21 – – – – – – 21 – – – –

-4 -6.8 – – – – – – – – – – – – –

-5 -7.8 – – – – – – – – – – – – –

-6 -8.8 – – – – – – – – – – – – –

-7 -9.8 – – – – – – – – – – – – –

-8 -10.8 – – – – – – – – – – – – –

(1) Percent of glycol by weight

- = Operation is not permitted

CAUTION!

Glycol concentration should always by equal or higher to the value given in this table. However, if the concentration is much higher than the value given, unit capacity will be

uselessly reduced.

With ethylene glycol

Standard Units

High Efficiency units/Extra efficiency units

%

Glycol (1)

%

Glycol (1)

%

Glycol (1)

%

Glycol (1)

%

Glycol (1)

%

Glycol (1)

%

Glycol (1)

%

Glycol (1)

%

Glycol (1)

%

Glycol (1)

%

Glycol (1)

%

Glycol (1)

%

Glycol (1)

Chilled

Water

Set Point

Leaving

Water

Temperature

Cutout

Evaporator Fluid

Delta T °C

With monopropylene glycol

Standard Units

High Efficiency units/Extra efficiency units

%

Glycol (1)

%

Glycol (1)

%

Glycol (1)

%

Glycol (1)

%

Glycol (1)

%

Glycol (1)

%

Glycol (1)

%

Glycol (1)

%

Glycol (1)

%

Glycol (1)

%

Glycol (1)

%

Glycol (1)

%

Glycol (1)

Chilled

Water

Set Point

Leaving

Water

Temperature

Cutout

Evaporator Fluid

Delta T °C

Loading...

Loading...