28 CNT-SVX08F-EN

Sequence of Operations for Generic Mode

Sequence of Operations for Generic Mode

Configuring the MP501 in generic mode will control a variety of applications. The MP501 controls

a process based on an input that is one of the following:

• Temperature

•Percent

• Pressure

•Flow

• Parts per million (ppm)

Note: Th

e generic mode applications

do not follow a LonMark profile.

Power-up Sequence

When 24 Vac power is initially applied to the MP501, the following sequence occurs:

10. The Status LED goes on.

11. All the outputs are turned off.

12. The controller reads all the inputs to determine their initial values.

13. A user-adjustable (power-up control wait) delay timer begins. If set to less than 10 seconds, a

10

-second wait

will be applied.

14. The Status LED goes off.

15. The delay timer expires.

16. The Status LED goes on.

17. If a hardwired input (4–20 mA)

is no

t detected and no value has been communicated, the

actuator output is overridden to closed and generates a Process Input Failure diagnostic.

18. Normal operation begins if no diagnostics have been generated.

Loop Enable/Disable

The proportional, integral, derivative (PID) control loop in the controller can be enabled by either

the binary input (BI1) on the board or by a communicated signal. The communicated signal has

priority over the hardware input. The PID loop is enabled if the communicated signal is invalid and

nothing is connected to the hardware input (refer toTable 6).

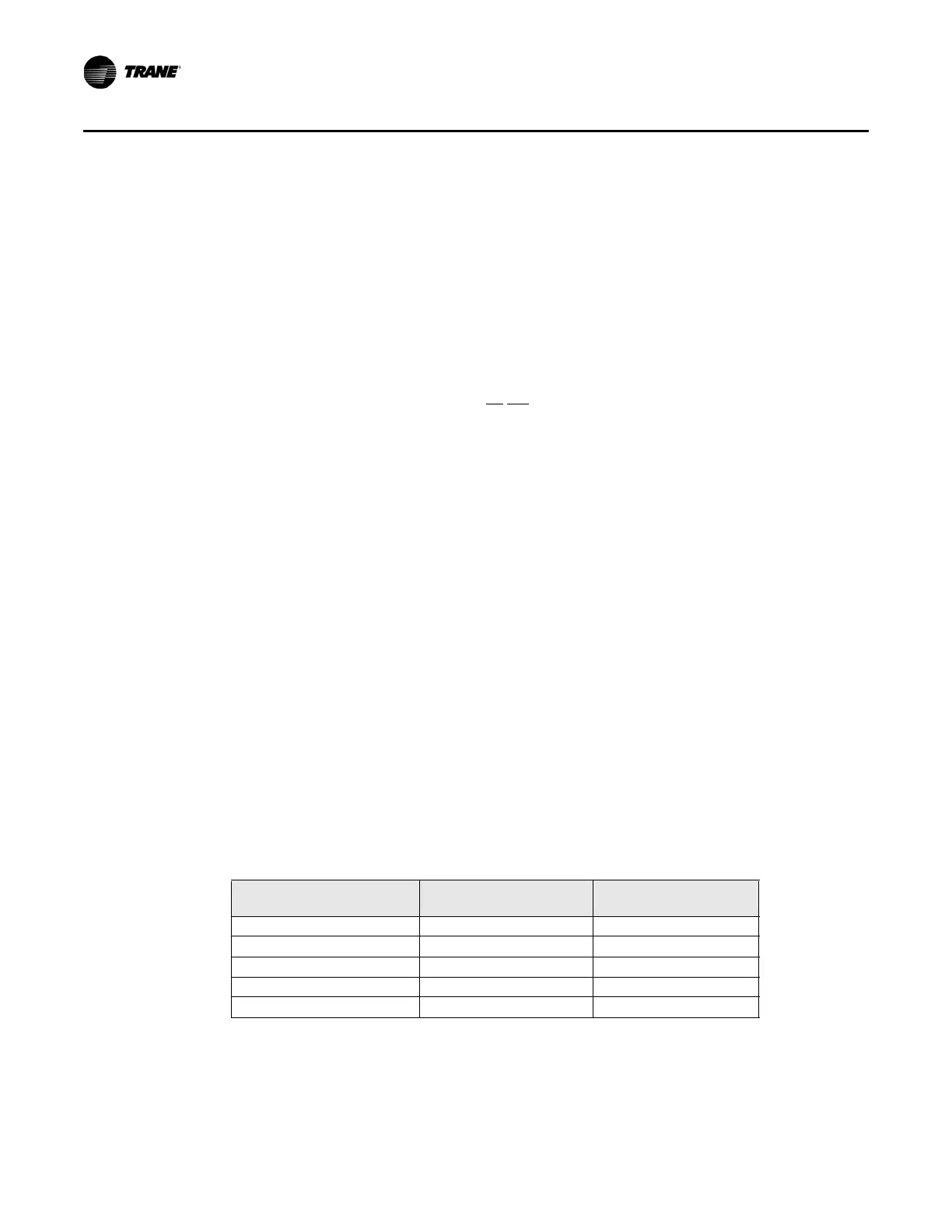

Table 6. Loop enable summary

Communicated Signal

(nviLoopEnable) Hardware Input (BI1) The PID Loop Is…

Enable Does not matter Enabled

Disable Does not matter Disabled

Not valid Enable Enabled

Not valid Disable Disabled

Not valid Invalid Enabled

If the PID loop is enabled, the controller compares the input to its setpoint and calculates an output

between 0% and 100%. The controller takes that PID output value and controls the outputs

appropriately. If the PID loop is disabled, the outputs go to predefined positions. Refer to the

section, “PID Control,” p. 29l.

Loading...

Loading...