Maintenance

26

Changing Oil

Change oil while engine is still

warm from recent operation.

Warm oil flows more freely and

carries away more impurities.

1. Stop engine, wait for parts to

stop moving, and disconnect

spark plug wire.

2. Remove dipstick (Z, Figure 5-1).

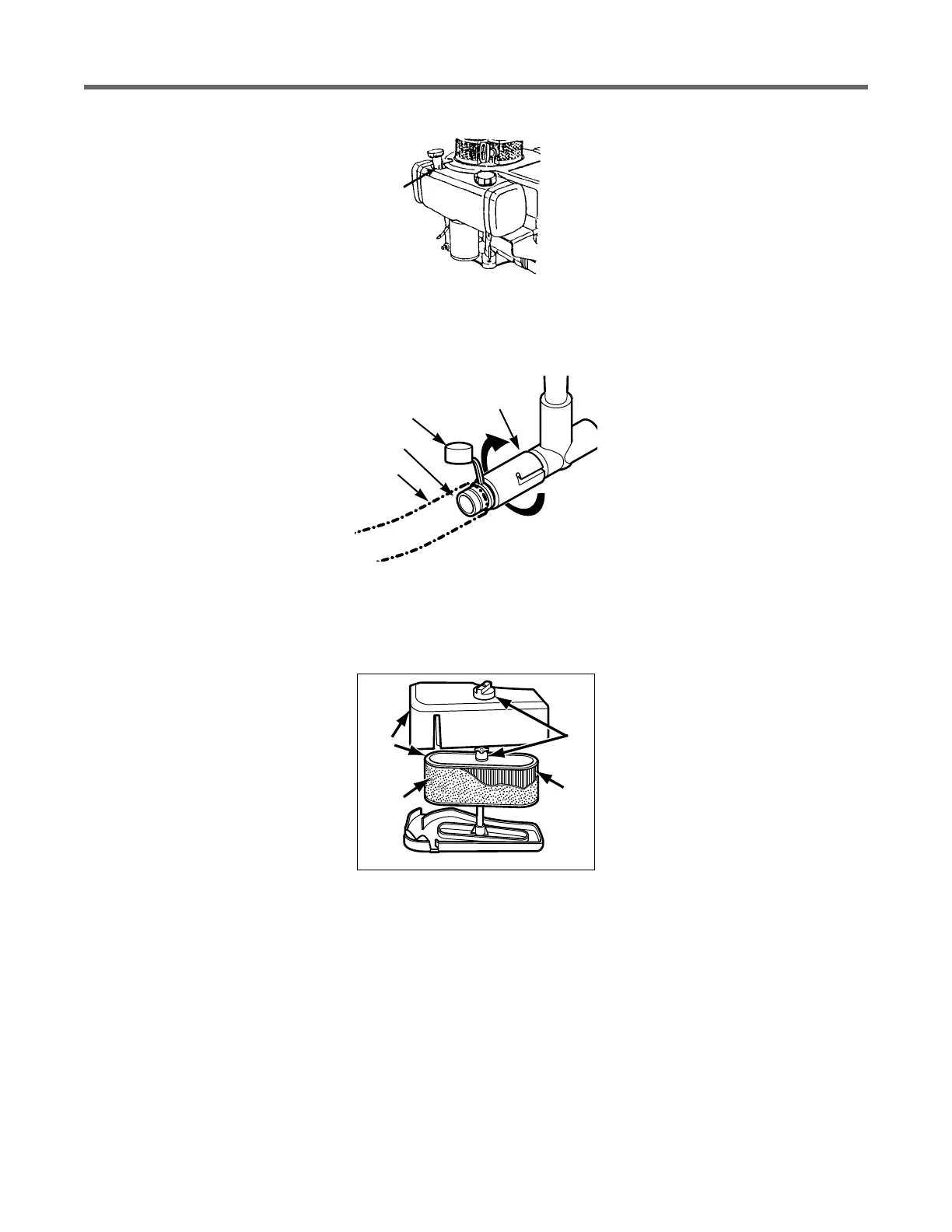

3. Remove protective cap (A,

Figure 5-2) to expose oil drain

port (B).

4. Push oil drain hose (D) (in-

cluded in hardware bag with unit)

onto oil drain port. Route other

end of hose to an appropriate oil

collection receptacle.

5. Twist oil drain fixture (C) to the

open position. Pull out. Drain oil

completely.

6. Push in and twist oil drain fix-

ture to the closed position. Remove

drain hose. Replace protective cap

(A).

7. Refill engine with fresh oil and

securely replace dipstick.

NOTE: Please dispose of all waste

materials in an ecologically re-

sponsible manner. Use proper

waste material storage containers

ENGINE CLEANING

• Stop engine, wait for parts to

stop moving, disconnect spark

plug wire, and allow engine to

cool before inspecting or clean-

ing engine.

• Daily or more often, before run-

ning engine, remove grass and

chaff from recoil finger guard or

rotating screen to prevent engine

damage caused by overheating.

Also keep cooling vanes, governor

linkage, springs and controls free

of debris.

• Daily or more often, before run-

ning engine, clean muffler area

(be sure muffler is cool) to remove

all grass and combustible debris.

If engine is equipped with a spark

arrestor screen, remove assembly

every 50 hours for

cleaning and inspection. Replace

if damaged.

• Grass or chaff may clog engine's

air cooling system, especially after

prolonged operation cutting tall,

dry grass. See engine owner's

manual for instructions on clean-

ing underneath the engine blower

housing.

AIR CLEANER SERVICE

Improper air cleaner maintenance

can cause engine damage. Refer to

the engine owner's manual for

more complete air cleaner service

information.

SERVICE SCHEDULE:

Outer foam pre-cleaner - wash and

re-oil every 25 operating hours or

every season, whichever occurs

first.

Inner paper cartridge - clean or re-

place every 100 operating hours or

every season, whichever occurs

first.

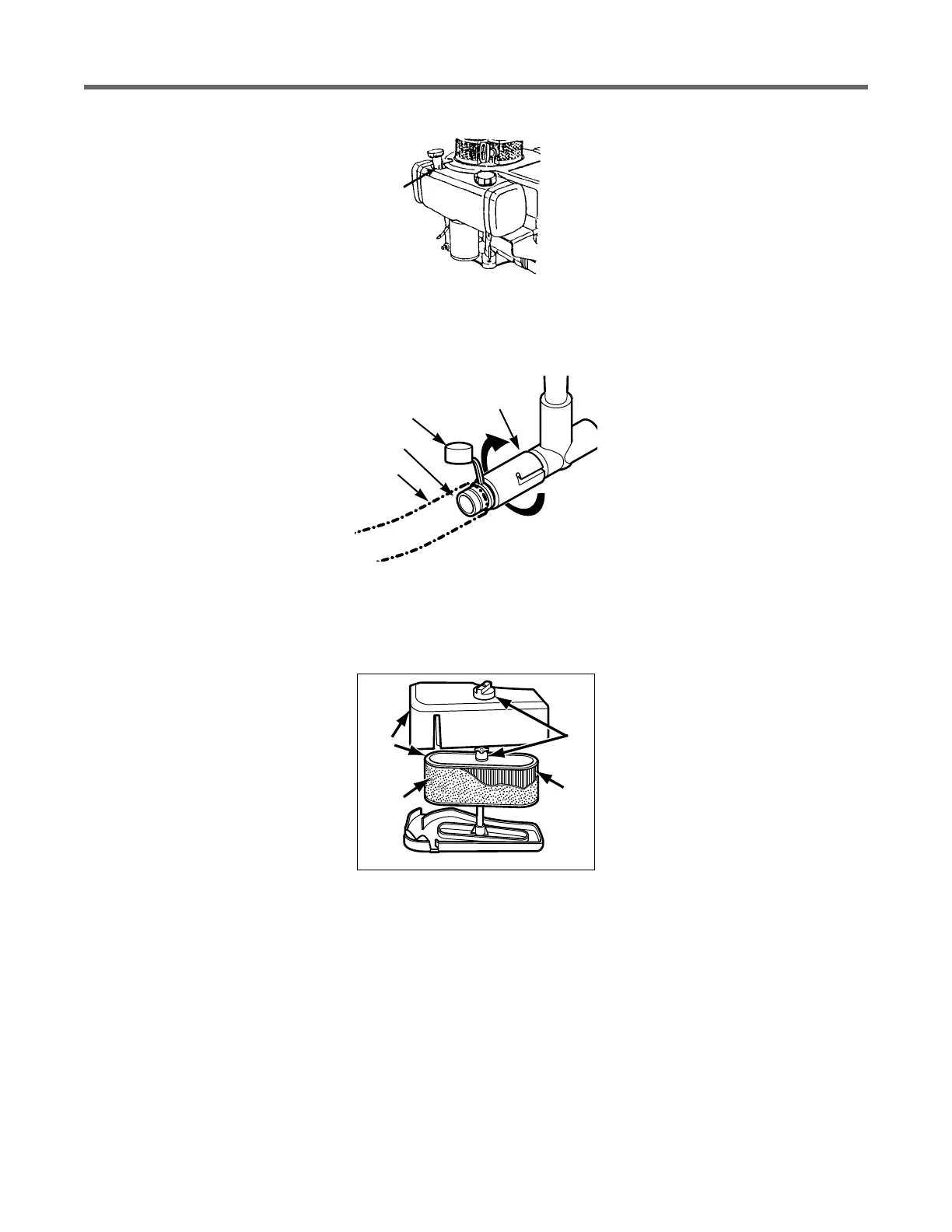

To Service Air Cleaner (Figure 5-3)

1. Stop engine, wait for parts to

stop moving, and disconnect

spark plug wire.

2. Unscrew mounting screws

and/or remove knobs (D). Remove

covers (E). Remove paper car-

tridge (B) and foam pre-cleaner

(A). Separate foam pre-cleaner

from paper cartridge.

3. Wash foam pre-cleaner (A) in

liquid detergent and warm water.

Squeeze dry in a clean cloth.

4. Saturate foam pre-cleaner in

clean engine oil. Wrap in clean,

absorbent cloth and squeeze to re-

move all excess oil.

5. Replace paper cartridge (B) if

necessary.

6. Reassemble air cleaner compo-

nents. Tighten knobs/screws (D)

securely. Secure cover assembly

(E) on air cleaner body.

Figure 5-1: Briggs and Stratton en-

gine oil fill.

Figure 5-2: Oil drain.

Z

C

A

B

D

Figure 5-3: Briggs and Stratton air

cleaner assembly.

E

D

B

A

Loading...

Loading...