Maintenance

32

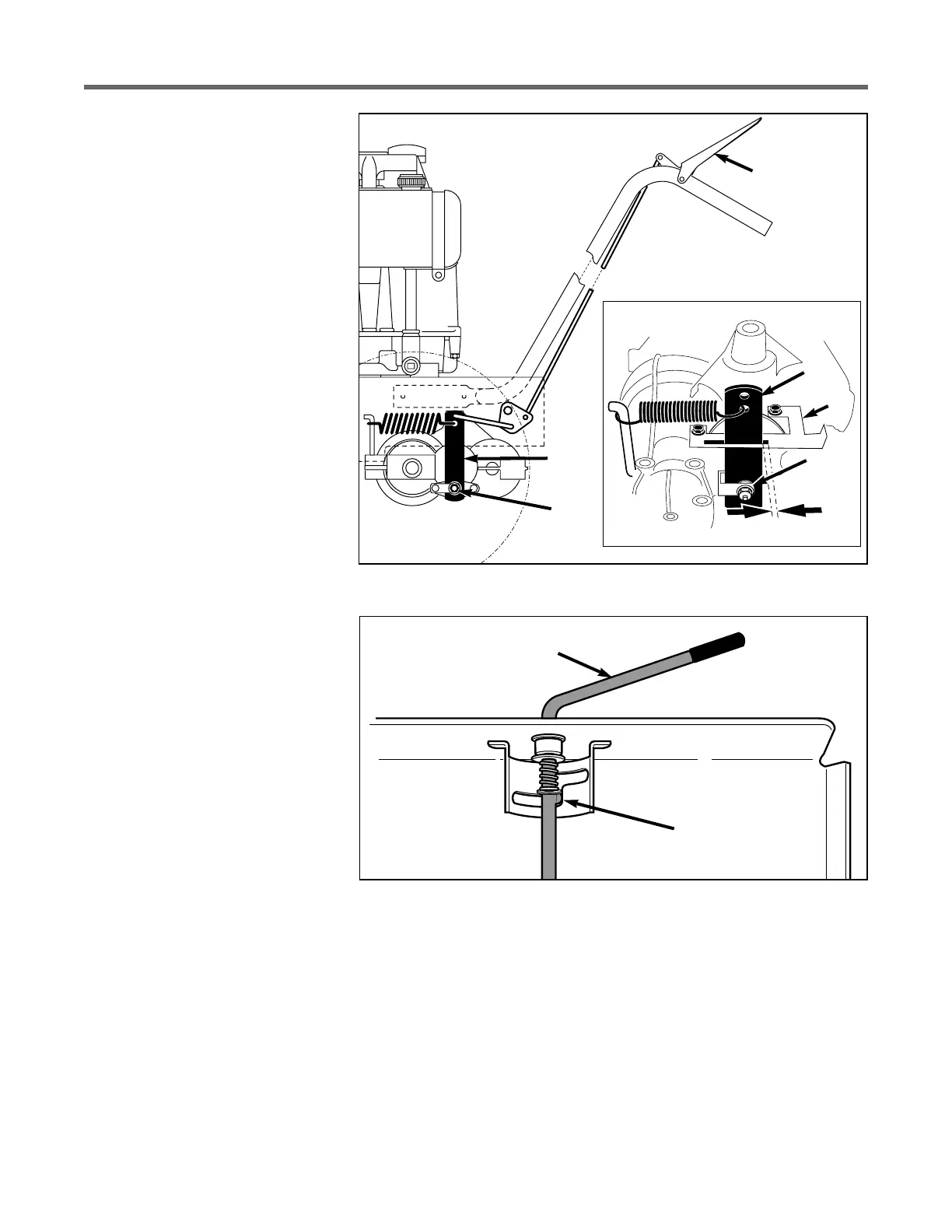

Figure 5-13: Wheel brake adjustment.

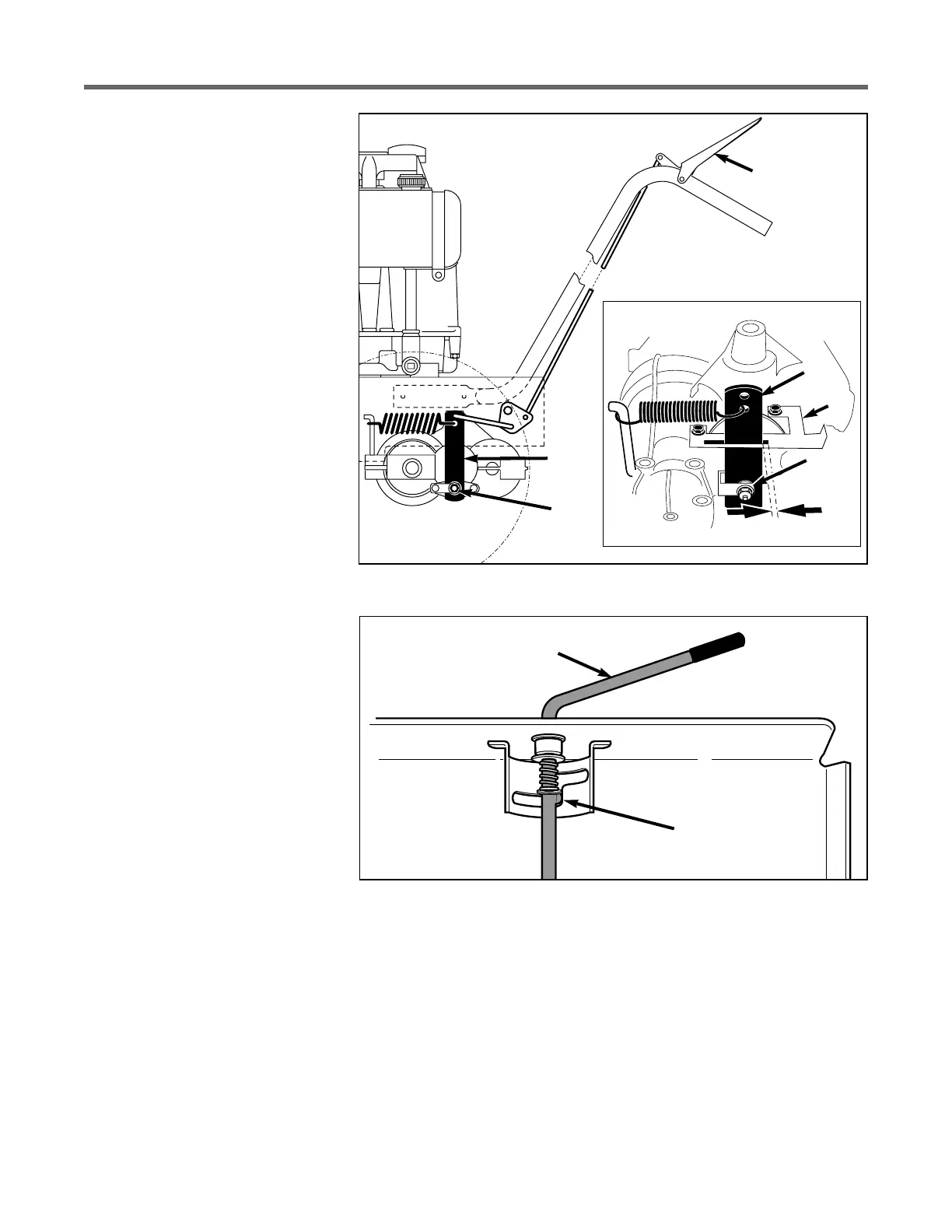

Figure 5-14: Gear Select Lever in neutral (N) position.

WHEEL BRAKE ADJUSTMENT

This adjustment may be required

if the machine does not hold on a

hill with the Operator Presence

Control disengaged, or if the brake

drags with the Operator Presence

Control engaged and the transmis-

sion in neutral.

1. Stop engine, wait for all parts

to stop moving, and disconnect

spark plug wire.

2. Disengage (release) the

Operator Presence Control (M,

Figure 5-13).

3. Slowly adjust at nut (O), if nec-

essary, until the distance between

the back of brake arm (N) and

bracket (P) is 3/8”-5/16". Use

small adjustments (1/4 turn maxi-

mum). NOTE: It may be neces-

sary to relieve spring tension when

decreasing distance. To do so,

have an assistant engage the

Operator Presence Control while

you adjust the nut.

TRANSMISSION NEUTRAL

ADJUSTMENT

Follow this procedure to adjust

neutral on the transmission.

1. Stop engine, wait for all parts

to stop moving, and disconnect

spark plug wire.

2. Rotate shift rod (I, Figures 5-14

and 5-15) clockwise until it stops

in the neutral (N) position (from

forward gear positions).

3. Hold down Operator Presence

Control (M, Figure 5-13) and push

unit forward and backward. Unit

should move freely. If not, con-

tinue with Step 4.

4. Remove cotter pin securing

shift link (P, Figure 5-15) to shift

rod (I).

5. Move shift arm (X) back and

forth as necessary into each detent

until transmission is in neutral.

NOTE: Moving shift arm (X)

clockwise all the way to the left,

and then one notch back counter-

clockwise, should put transmission

into neutral. When transmission is

in neutral, unit will move freely

when pushed while holding the

Operator Presence Control lever

down. If transmission is NOT in

neutral, there will be a slight drag

on the wheels when pushing unit.

6. When shift arm (X) is in neutral

position, rotate shift link (P) until

hooked end fits back into hole in

bottom end of shift rod (I).

NOTE: Shift rod (I) must be held

in the neutral position (see Figure

5-14) while shift link (P) is

adjusted.

7. Secure shift link (P) into shift

rod (I) with cotter pin removed

earlier.

8. Re-check neutral by pushing

unit back and forth and shifting

lever (I) from reverse to neutral. A

small fine-tune adjustment may be

required.

M

N

O

N

O

P

3/8”-

5/16”

I

Detent for

Neutral Position

Loading...

Loading...