23

OVEN SYSTEMS

The Conveyor System

This section contains information about the

following components, as well as testing

procedures:

- G

ear Drive (Conveyor Motor)

- G

ear Drive (Conveyor Motor) Speed

Contr

oller (CMSC)

G

ear Drive (Conveyor Motor)

The conveyor motor is a 1610 RPM, 3-phase

motor with a built-in H

all E

ffect Sensor. The

speed of the conv

ey

or motor is controlled by the

v

oltage fr

equency applied to the windings from

the CMSC.

The H

all Effect Sensor sends a DC

pulse back to the contr

ol boar

d to v

erify motor

speed.

The contr

ol boar

d uses these pulses to

determine the output DC v

oltage to the

CMSC.

Single-belt HhC 2020 ovens contain one gear

drive. Dual-belt ovens contains two gear drives.

T

esting Procedure

1.

Disconnect line voltage from the unit.

2.

T

ake a resistance reading of the motor

windings and use F

igur

e 33 to v

erify that

the r

esistance r

eadings ar

e correct.

3.

I

f the r

esistance r

eadings are correct,

r

econnect the motor wiring and then apply

line v

oltage to the unit and check for

voltage applied to the motor windings.

4.

If no voltage is present, ensure the CMSC is

operating pr

operly (see below).

5. If CMSC is operating properly, inspect the

wir

e harness for damage or shorts.

6.

If the wire harness is intact and undamaged,

and the CMSC is operating pr

operly, the

gear drive is damaged or defective and must

be r

eplaced.

G

ear Dr

ive (Conveyor Motor) Speed

C

on

troller (CMSC)

The CMSC converts single-phase line voltage to

a thr

ee-phase output, and contr

ols the speed of

the gear driv

e via fr

equency output. The CMSC

r

eceiv

es an input voltage (0-10 VDC) from the

control board and adjusts the frequency output

to the gear drive.

Testing Procedure

WARNING: Capacitors within the CMSC

can retain charge after power is removed.

Exercise extreme caution when handling the

terminals.

WARNING: DO NOT connect incoming

AC power to output terminals U, V, or W.

This will seriously damage the Conv

eyor

M

otor S

peed Controller.

1.

E

nsur

e that no faults appear on the display

of the CMSC during o

v

en operation.

The

control will display the frequency output if

the system is operating correctly.

2. Check the input voltage on terminals L1 &

L2 (200-240

VAC) and the DC voltage

input on terminals 0V & AI (0.1-10

VDC).

3.

I

f no input voltage is present, inspect the

wire harness for damage or shorts (pages

37-38).

4. If DC control voltage is not present, check

v

oltage output at I/O board. If no voltage is

pr

esent at the I/O board, replace the board.

J10-A13 to J9-C6 = front belt

J10-A14 to J10-A6 = r

ear belt.

5. Check ohms of motor (Figure 33).

6.

If wire harness is intact and undamaged,

the CMSC is damaged or defective and

must be replaced.

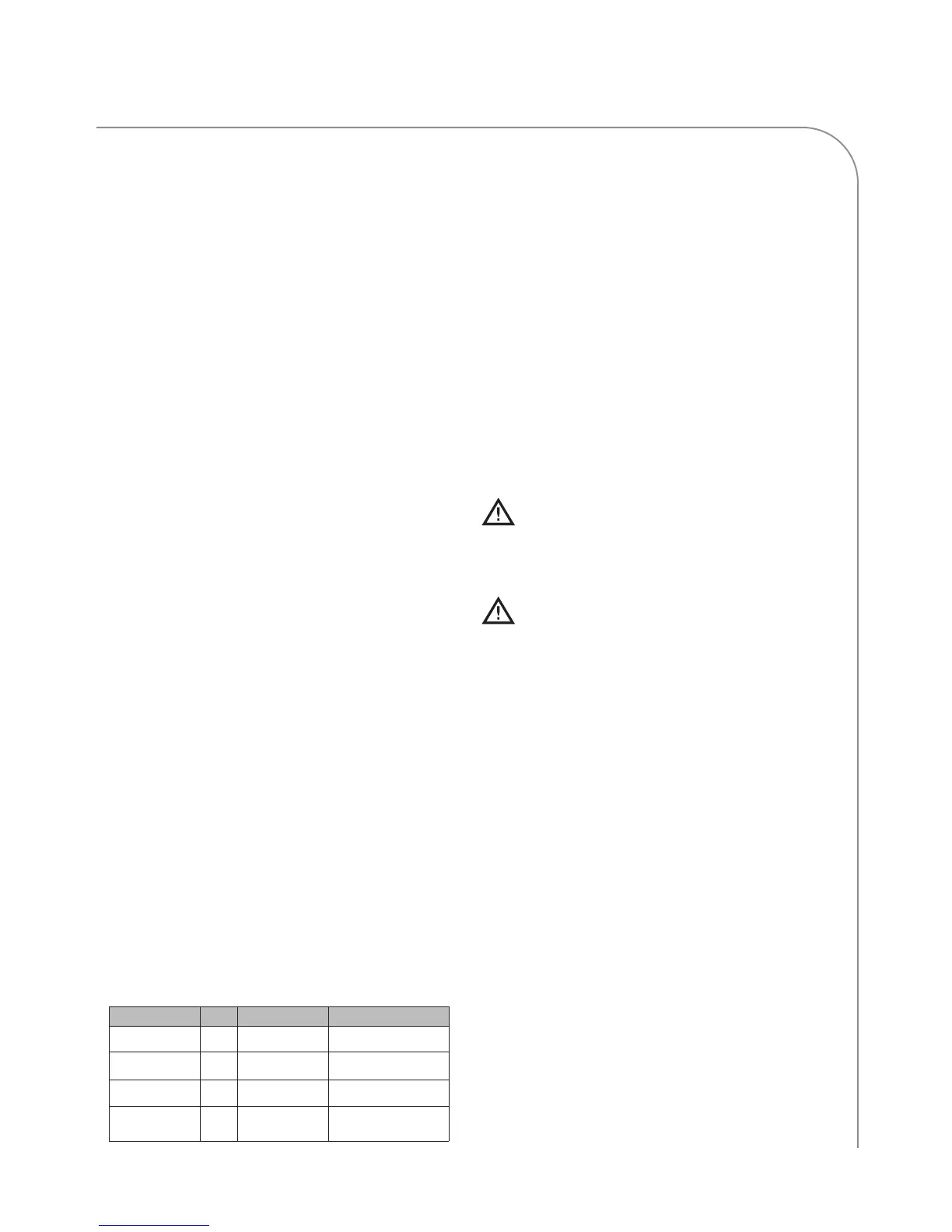

To From Description Expected Resistance

White G

rey

W

inding (A-B)

215-217 W

White Black Winding (A-C)

215-217 W

Grey Black Winding (B-C)

215-217 W

White, Grey, or

Black

G

reen

Windings to

chassis

O

pen

Figure 33: Conveyor Motor Ohm Chart

Loading...

Loading...